Aluminum foil annealing process

An annealing process and aluminum foil technology, which is applied in the field of aluminum and aluminum alloys, can solve the problems of insufficient heating efficiency, influence efficiency, and insufficient internal grain size, and achieve good finished version quality, improved production efficiency, and good version quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An annealing process for aluminum foil, the aluminum foil is 5182 alloy, the size is 0.12×1580mm, three rolls of aluminum materials are annealed together in a furnace, the difference in outer diameter is 30mm, and the difference in width is 10mm, which includes the following steps:

[0022] (1) Straighten and level the aluminum foil coils one by one on the stretch-bending straightening machine, and take a sample of 2m to the platform to detect the version. The measured wave height is 1.8mm, the wave distance is 600mm, and the quality of the version is good;

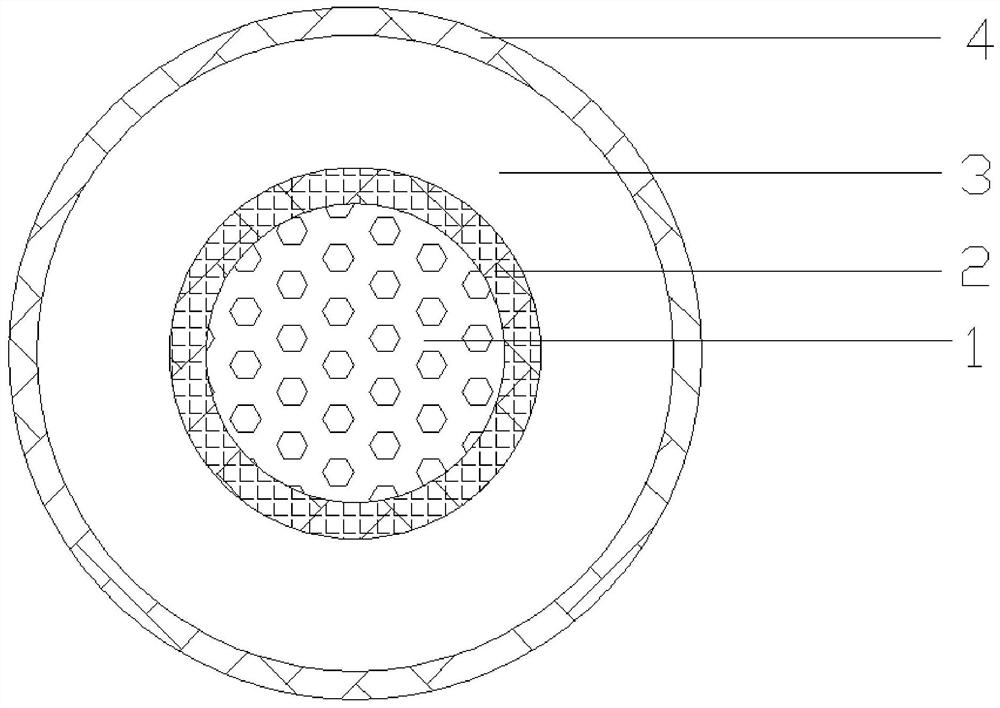

[0023] (2) if figure 1 As shown, on the steel sleeve 1 with a width of 1850mm, the inner ring of the 5182 alloy 0.35×1700mm is used for coiling and production. The steel sleeve is used for coiling the aluminum foil product to be annealed; then the coiled material to be annealed foil is coiled to form the aluminum foil layer 3, and the 5182 alloy 0.35×1700mm product is used to coil the inner ring for production, in ...

Embodiment 2

[0027] An annealing process for aluminum foil, the aluminum foil is 5052 alloy, the specification is 0.2×1280mm, 4 rolls of aluminum materials are annealed together in a furnace, the difference in outer diameter is 100mm, and the difference in width is 50mm, which includes the following steps:

[0028] (1) Straighten and level the aluminum foil coils one by one on the stretch-bending straightening machine, and take a sample of 2m to the platform to detect the pattern. The measured wave height is 2mm, the wave distance is 340mm, and the pattern quality is good;

[0029] (2) if figure 1 As shown, on the steel sleeve 1 with a width of 1850mm, the inner ring of the 5052 alloy 0.3×1400mm is used for coiling and production. The steel sleeve is used for coiling the aluminum foil product to be annealed, and then the coiled material to be annealed foil is formed into the aluminum foil layer 3, and the 5052 alloy 0.3×1400mm product is used to coil the inner ring for production, in 5052 ...

Embodiment 3

[0033] An annealing process for aluminum foil, the aluminum foil is 5005 alloy, the specification is 0.15×1430mm, 4 rolls of aluminum materials are annealed together in a furnace, the difference in outer diameter is 50mm, and the difference in width is 100mm, which includes the following steps:

[0034] (1) Straighten and level the aluminum foil coils one by one on the stretch-bending straightening machine, and take a sample of 2m to the platform to detect the pattern. The measured wave height is 1.6mm, wave distance is 280mm, and the pattern quality is good;

[0035] (2) if figure 1 As shown, on the steel sleeve 1 with a width of 1850mm, the inner ring of the 5005 alloy 0.5×1600mm is used for coiling and production. The steel sleeve is used for coiling the aluminum foil product to be annealed, and then the coiled material to be annealed foil is formed into the aluminum foil layer 3, and the 5005 alloy 0.5×1600mm product is used to coil the inner ring for production, in 5005 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com