Steel structure box-type column beam and manufacturing method thereof

A box-shaped column beam and steel structure technology, which is applied to other manufacturing equipment/tools, manufacturing tools, truss structures, etc., can solve the technical requirements that are difficult to meet penetration welding, poor weld reliability, slow production speed, etc. Solve problems, achieve the effect of easy control of welding quality and process, improved work efficiency, and less likely to hurt people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A steel structure box-shaped column beam and its manufacturing method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

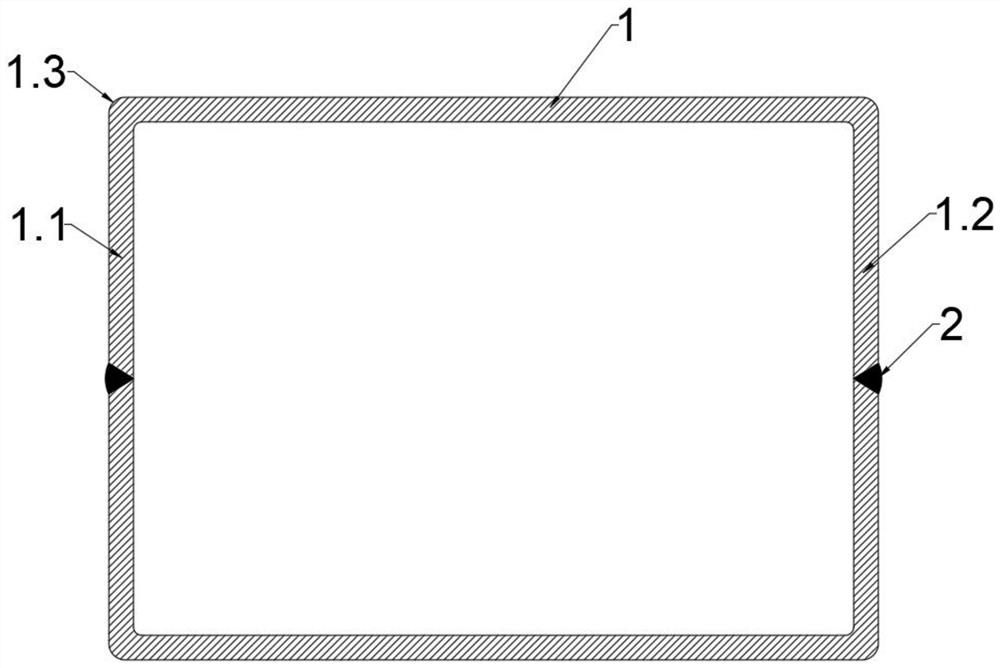

[0016] combined with figure 1 , a steel structure box-shaped column beam, including symmetrically arranged steel plates 1, two steel plates 1 are connected by welding; both ends of the steel plates 1 are bent in the same direction to form a first bending part 1.1, a second bending part 1.2, the first bending part 1.1 and the second bending part 1.2 have the same length, the first bending part 1.1 and the second bending part 1.2 form an angle of 90° with the main body of the steel plate 1, and the two The first bending part 1.1 of the steel plate 1 is flush, the second bending part 1.2 of the two steel plates 1 is flush, and the two first bending parts 1.1 are fixed by flat welding at the overlap, and the two The second bending part 1.2 is fixed by flat welding at the overlapping joint; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com