Assembly type indoor metal partition wall module installation and transportation integrated device

A prefabricated, metal technology, applied to walls, building components, buildings, etc., can solve problems such as low installation efficiency, achieve high installation efficiency, beautiful decorative effects, and avoid cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

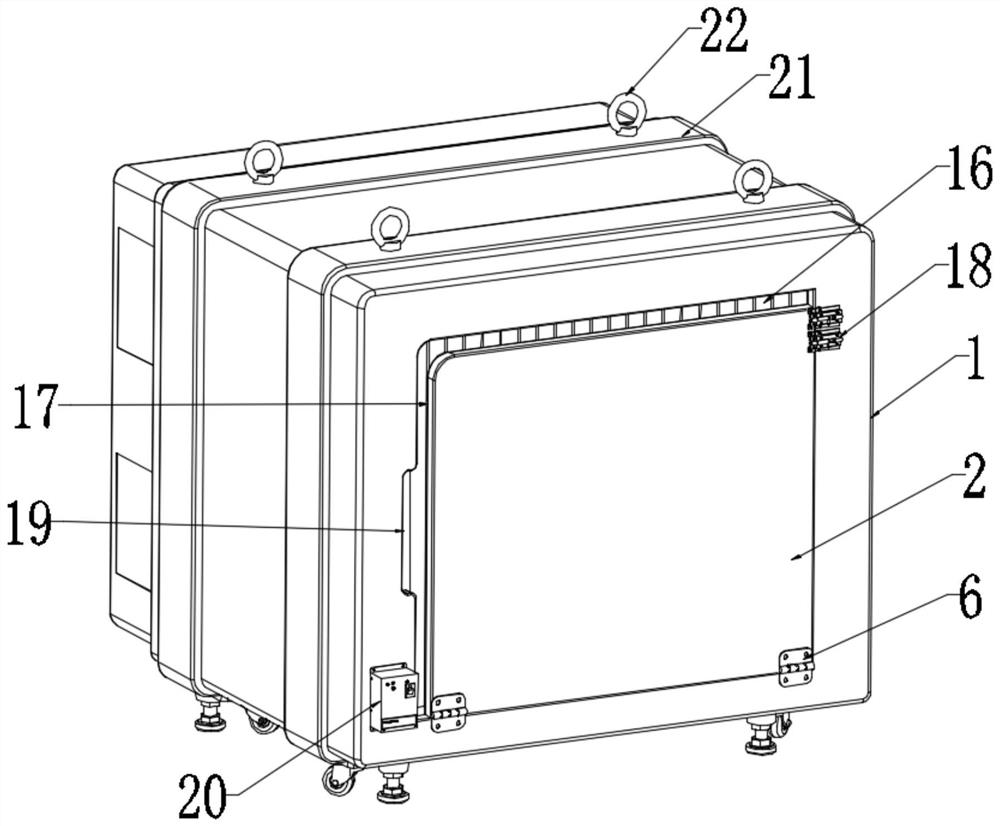

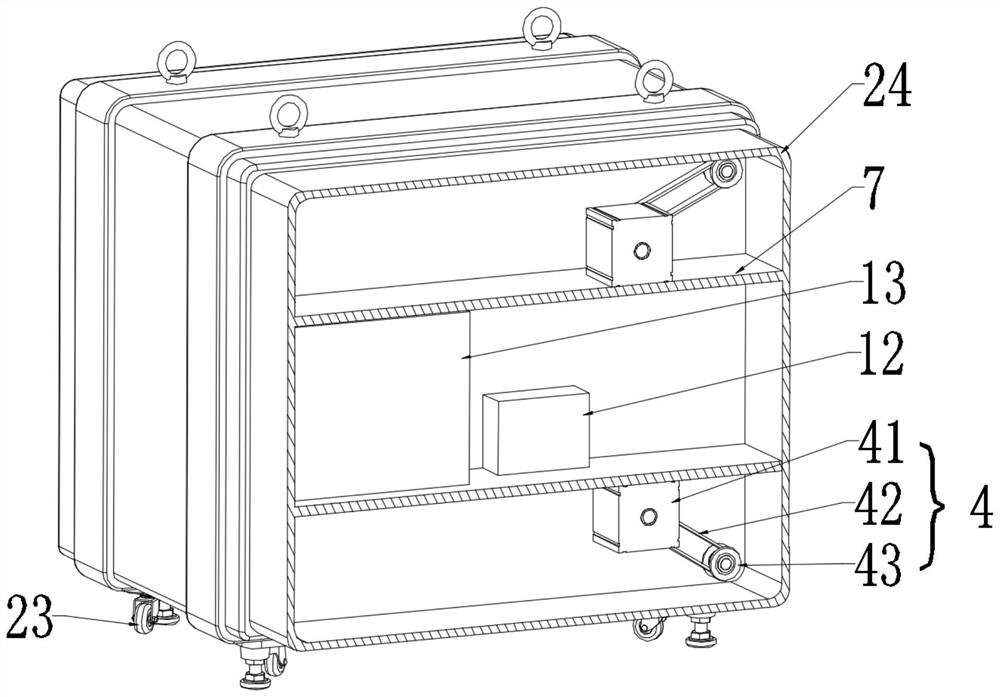

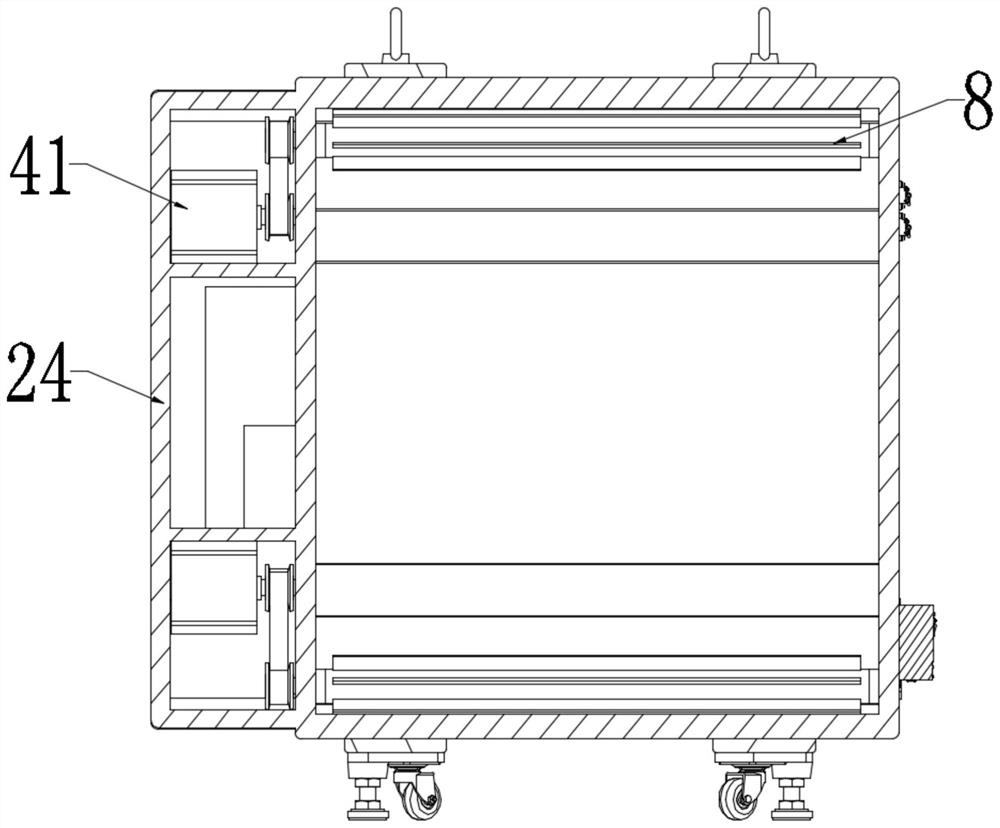

[0029] see Figure 1 to Figure 6 , this embodiment provides a prefabricated indoor metal partition wall module installation and transportation integrated device, which includes a box body 1, a box door 2, a transmission mechanism 3 and a transmission drive mechanism 4, and the front end of the box body 1 is provided with an opening 5 , the box door 2 is clamped in the opening 5, and the edge of the box door 2 and the opening 5 is connected by a hinge 6, and the transmission mechanism 3 is two groups symmetrically arranged at the upper and lower ends of the box body 1, and the box body 1 is far away from the opening 5 A control box 24 is arranged on the outer wall of the control box 24, and the transmission drive mechanism 4 is arranged in the control box 24, and the transmission drive mechanism 4 is connected with the transmission mechanism 3, and the transmission mechanism 3 includes a driving roller 31, a driven roller 32 and a conveyor belt 33, and the driving roller 31 The...

Embodiment 2

[0038] see Figure 1 to Figure 6, the figure shows a prefabricated indoor metal partition wall module installation and transportation integration device provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments The bottom surface of the upper conveyor belt 33 is lower than the top surface of the opening 5, and the top surface of the lower conveyor belt 33 is higher than the bottom surface of the opening 5, so that the wall panel body 10 can be taken out from the opening 5 smoothly.

[0039] Specifically, see Figure 1 to Figure 6 , the inner wall of the conveyor belt 33 is provided with a plurality of driving grooves 14, the driving grooves 14 are equidistantly and evenly arranged on the conveyor belt 33, and the driving roller 31 is provided with a plurality of driving bosses 15, and the driving boss 15 is on the driving roller 31 Arranged uniformly at equal angles,...

Embodiment 3

[0042] see Figure 1 to Figure 6 , the figure shows a prefabricated indoor metal partition wall module installation and transportation integration device provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments : a first gap 16 is provided between the top surface of the box door 2 and the top surface of the opening 5, a second gap 17 is provided between one side of the box door 2 and the side of the opening 5, and the other side of the box door 2 and the side of the opening 5, and the door 2 and the box body 1 are fixed by the bolt 18. The serial number of the wall panel body 10 can be observed through the first gap 16, so as to select and install correspondingly. When loading the wall panel body 10 , open the door bolt 18 , rotate and open the box door 2 along the hinge 6 , align the card slot 9 and load the wall panel body 10 into the box body 1 .

[0043] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com