Mechanical sealing part of sewage treatment equipment

A technology of sewage treatment equipment and mechanical seals, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of improvement, unobvious sealing effect, undisclosed connection scheme between static ring and dynamic ring, etc., and achieve enhanced deformation ability, strengthen the sealing effect, and use the effect of strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

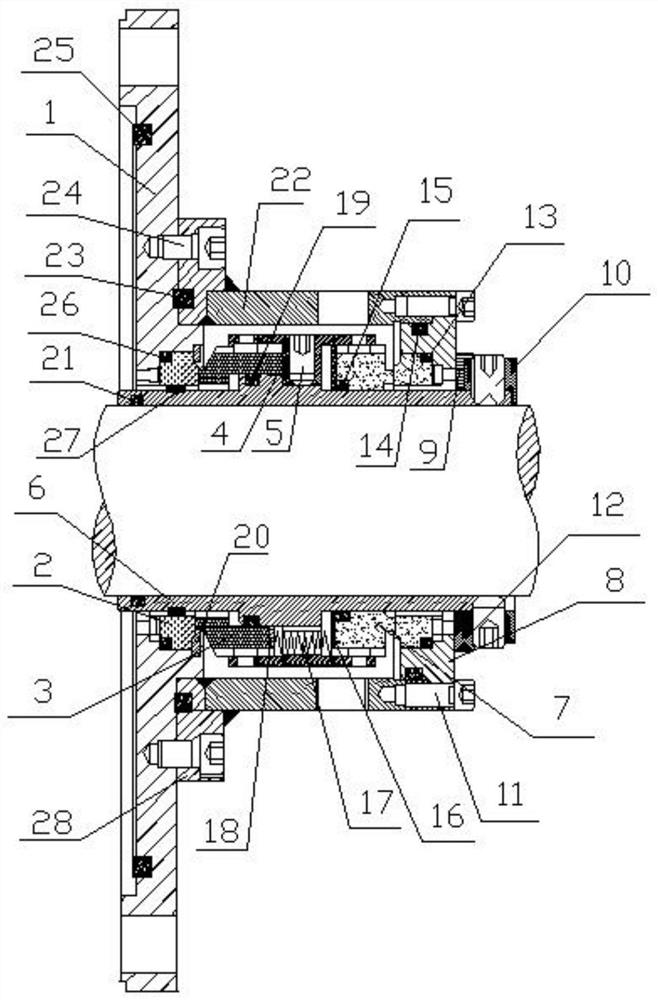

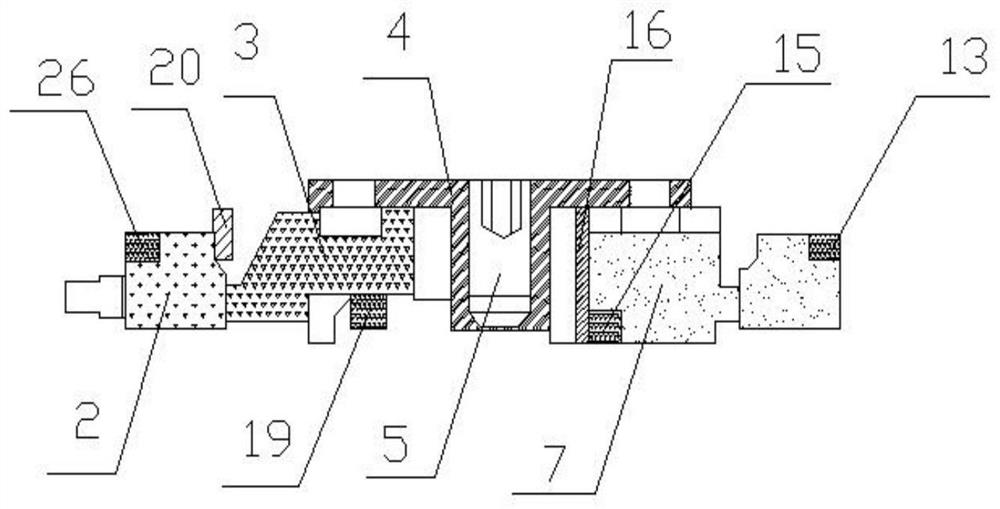

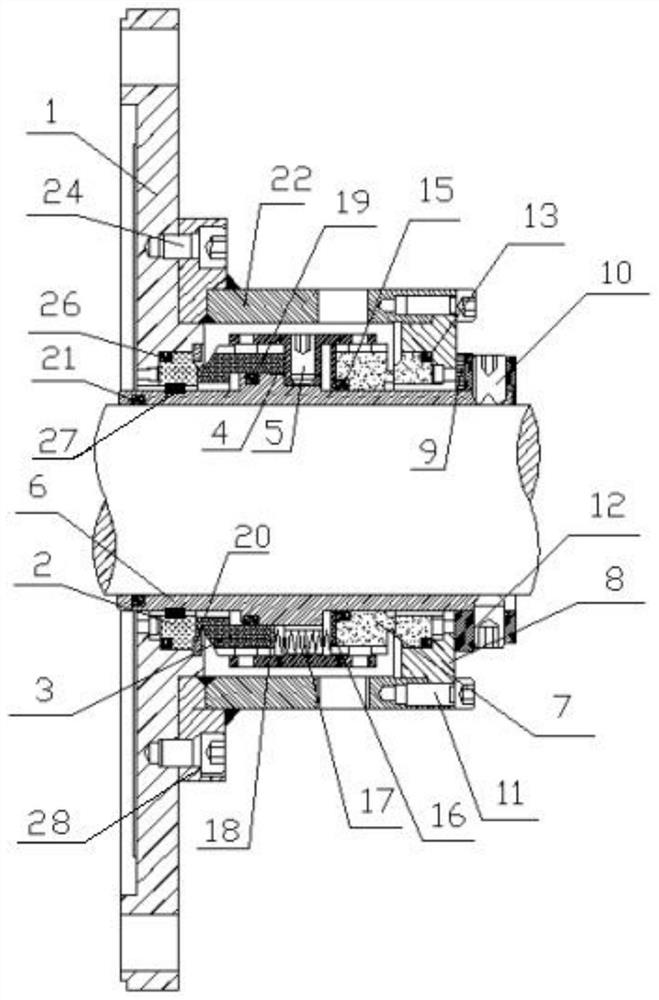

[0020] Such as image 3 with Figure 4 As shown, a mechanical seal for sewage treatment equipment includes a static ring assembly, a moving ring assembly, a gland assembly, a spring assembly, a medium end gland 1 and a mechanical seal shaft sleeve 6, and the medium end gland 1 is connected to the mechanical seal The shaft sleeve 6 is fixedly connected, and the static ring assembly includes the static ring 2 at the medium end, the static ring 26 at the atmospheric end, the static ring seal ring 13 at the atmospheric end located on the static ring 26 at the atmospheric end, and the static ring 2 at the medium end. The static ring seal ring 27 at the medium end, the static ring 2 at the medium end is connected to the gland 1 at the medium end, the positioning ring 9 is connected to the static ring 26 at the atmospheric end, and the static ring assembly is fixed, which can ensure the sealing of the device The positioning ring 9 is connected with the transmission ring 12 fixed on ...

Embodiment 2

[0024] Such as figure 1 with figure 2 As shown, a mechanical seal for sewage treatment equipment includes a static ring assembly, a moving ring assembly, a gland assembly, a spring assembly, a medium end gland 1 and a mechanical seal shaft sleeve 6, and the medium end gland 1 is connected to the mechanical seal The shaft sleeve 6 is fixedly connected, and the static ring assembly includes the static ring 2 at the medium end, the static ring 26 at the atmospheric end, the static ring seal ring 13 at the atmospheric end located on the static ring 26 at the atmospheric end, and the static ring 2 at the medium end. The static ring seal ring 27 at the medium end, the static ring 2 at the medium end is connected to the gland 1 at the medium end, the positioning ring 9 is connected to the static ring 26 at the atmospheric end, and the static ring assembly is fixed, which can ensure the sealing of the device The positioning ring 9 is connected with the transmission ring 12 fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com