Valve capable of exhausting and overflowing

A technology for overflow valves and valve casings, applied in safety valves, balance valves, valve devices, etc., can solve problems such as system paralysis, easy freezing and blockage, improper handling of pipeline insulation measures, etc., and achieve the goal of protecting system safety and improving heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

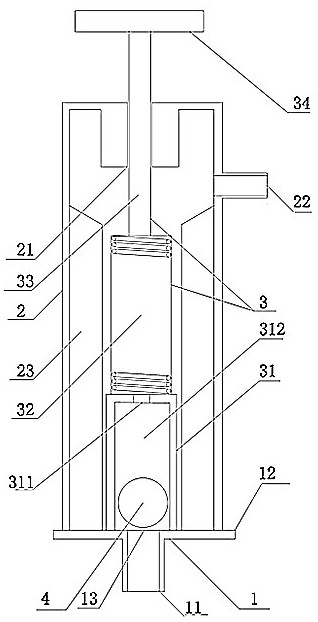

[0019] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

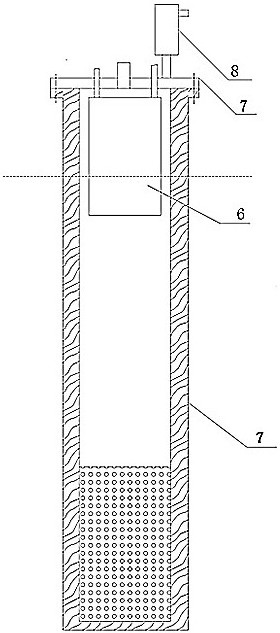

[0020] Such as figure 1 As shown, the exhaust and overflow valve 8 in this embodiment is composed of a base 1, a valve housing 2, a valve core 3, and a float 4. It is characterized in that: the valve housing 2 is assembled on the base 1, and the valve core 3 is assembled Inside the valve housing 2 , the float 4 is fitted in a float clock 31 of the spool 3 . Below the base 1 is a pipeline wire port 11 or a connecting flange, on the top is a valve casing fixing seat 12, and in the middle is a through hole 13. On the top of the valve casing 2 is a screw introduction hole 21, an overflow port 22 is reserved on one side, and a guide wing 23 is reserved on the inner side, and the lower port can be tightly combined with the valve casing fixing seat 12 on the base 1. The float clock 31 and the pressure regulating spring 32 can move up and down a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com