Detection method of BGA solder ball for integrated circuit packaging

An integrated circuit and detection method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as low pass rate, cracking of BGA solder joints, and unwelded solder joints, so as to improve the pass rate and reduce solder joints. Unsoldered points, the effect of the detection index system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

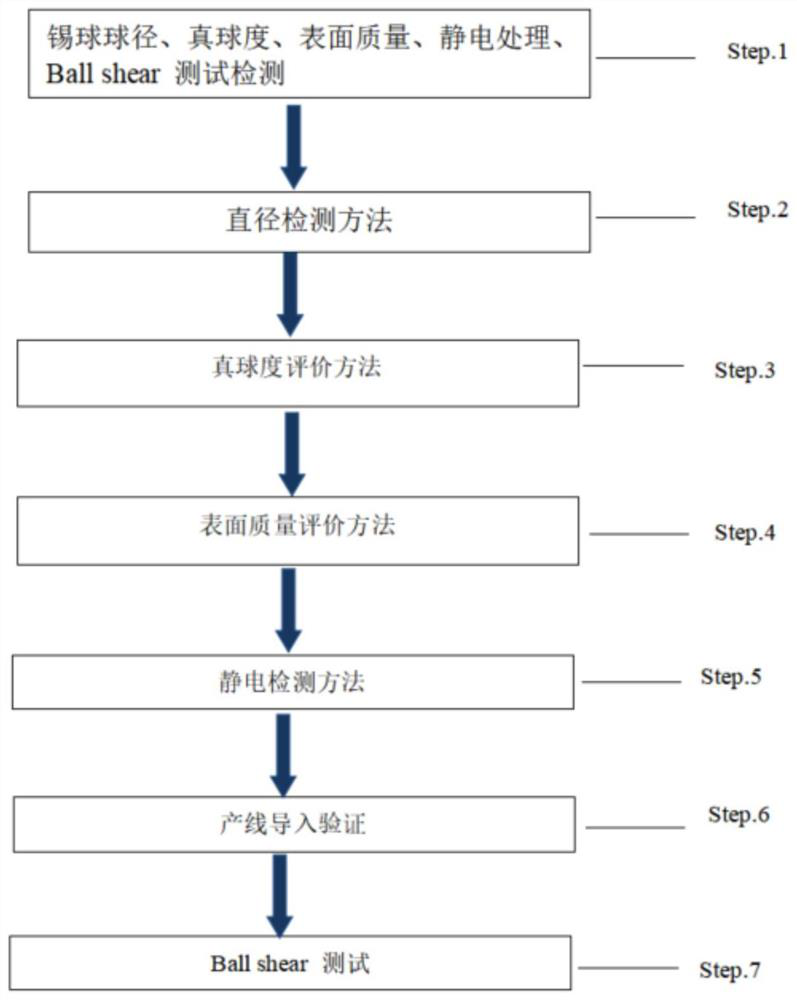

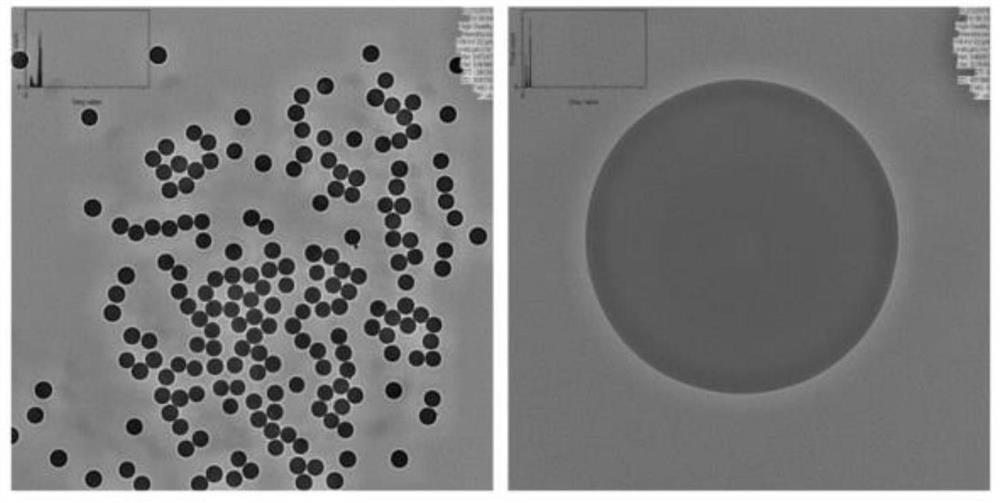

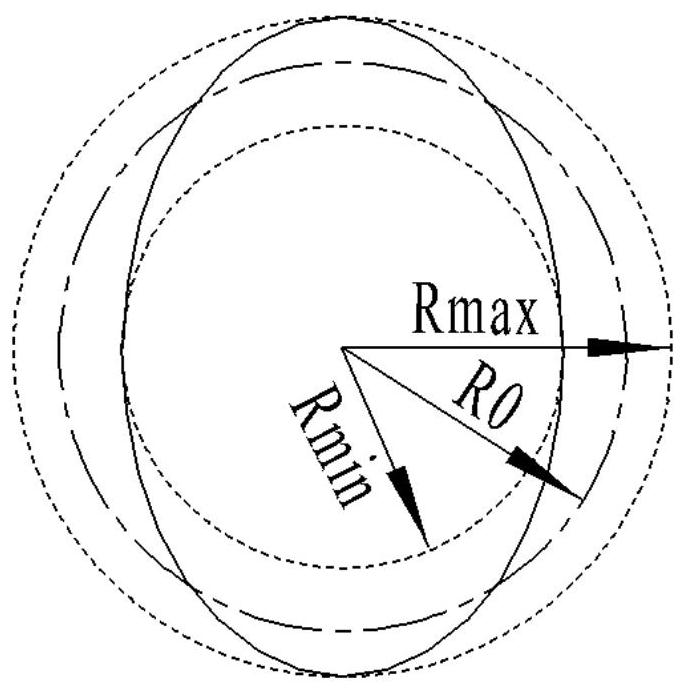

[0020] like Figure 1 to Figure 5 As shown, the present invention discloses a detection method of BGA solder balls for integrated circuit packaging, the technical solution adopted is to include Step.1, Step.2, Step.3, Step.4, Step.5, Step.6 and Step.7; said Step.1 includes solder ball diameter, true sphericity, surface quality, electrostatic treatment and Ball shear test; said Step.2 is diameter detection, specifically the ball diameter is tested by X-Ray method . In order to improve the detection efficiency and accuracy, the X-Ray magnification is selected to be 100-200 times. The average value of each solder ball diameter test three times is the final result. The allowable range of single ball diameter error is ±0.02mm, and the average ball diameter error range is ±0.01mm; the Step.3 is the evaluation of true sphericity, specifically the calculation of true sphericity of solder balls adopts the maximum ball diameter and minimum ball diameter of solder balls The ratio of t...

Embodiment 2

[0029] Embodiment 2 has the same steps as Embodiment 1, the difference is that the ball diameter and ball planting parameters are different

Embodiment 3

[0031] The steps of embodiment 3 are the same as those of embodiment 1, except that the diameter of the ball and the parameter of planting the ball are different.

[0032]In order to further illustrate the present invention, the detection results under the three different ball planting parameters of Example 2 and Example 3 are attached. The specific difference is that the solder balls in the above-mentioned embodiment 1 are solder balls manufactured by Japan Senju Metal Co., Ltd., and the ball diameter is 0.25 mm. Example 2 is a self-made solder ball, the ball diameter is 0.25mm, and the reflow temperature is 260 degrees. The solder ball has a high smoothness and flatness under magnification of 150 times, and no impurities and other pollutants, scratches, depressions, etc. can be seen with the naked eye. The surface of the brazing ball has no serious oxidation phenomenon, and the mass fraction of oxygen content on the surface is 7%. The ion blower blows at room temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com