Integrated light conversion glass diffusion plate and preparation method thereof

A light conversion and diffusion plate technology, applied in optics, optical components, instruments, etc., can solve the problems of increasing the thickness of the diffusion plate, increasing the assembly process of the diffusion plate, etc., and achieves improved stability, better color expression, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

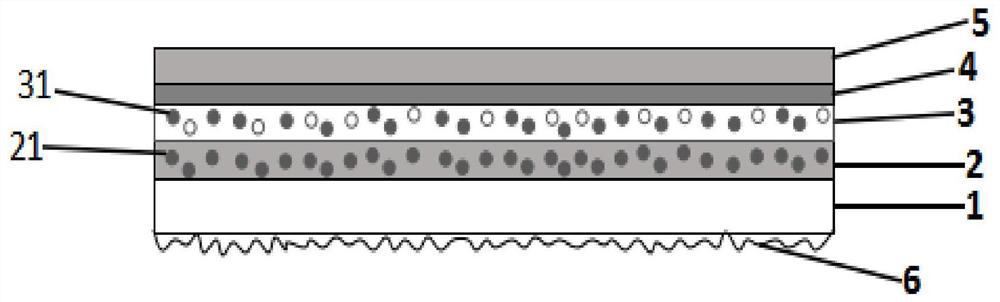

[0028] An integrated light-conversion glass diffusion plate, comprising a glass substrate 1, a diffusion layer 2, a quantum dot light conversion layer 3, an adhesive layer 4, and an optical film 5; On the surface, the quantum dot light conversion layer 3 is attached to the diffusion layer 2, and the optical film 5 is bonded on the quantum dot light conversion layer 3 through the adhesive layer 4 (the The material of the adhesive layer 4 is optical glue); the diffusion layer 2 is formed by coating the light diffusion material on the glass substrate 1 and curing; the light diffusion material includes the following components by weight percentage: resin 50 %, 35% of diffusion particles, 5% of silane coupling agent and 10% of diluent; the quantum dot light conversion layer 3 is dispersed in UV glue by quantum dots 31 and coated on the diffusion layer 2 and cured Forming.

[0029] Preferably, the light incident surface of the glass substrate 1 is provided with scattering patterns ...

Embodiment 2

[0038] An integrated light-conversion glass diffusion plate, comprising a glass substrate 1, a diffusion layer 2, a quantum dot light conversion layer 3, an adhesive layer 4, and an optical film 5; On the surface, the quantum dot light conversion layer 3 is attached to the diffusion layer 2, and the optical film 5 is bonded on the quantum dot light conversion layer 3 through the adhesive layer 4 (the The material of the adhesive layer 4 is optical glue); the diffusion layer 2 is formed by coating the light diffusion material on the glass substrate 1 and curing; the light diffusion material includes the following components by weight percentage: resin 45 %, 40% of diffusion particles, 12% of diluent and 3% of silane coupling agent; the quantum dot light conversion layer 3 is dispersed in silica gel ink by quantum dots 31 and coated on the diffusion layer 2 and cured Forming.

[0039] Preferably, the light incident surface of the glass substrate 1 is provided with scattering pa...

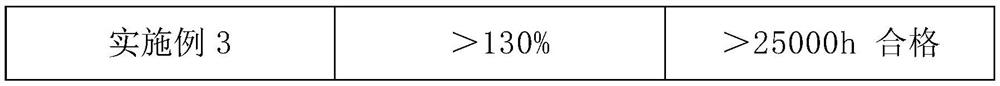

Embodiment 3

[0048] An integrated light-conversion glass diffusion plate, comprising a glass substrate 1, a diffusion layer 2, a quantum dot light conversion layer 3, an adhesive layer 4, and an optical film 5; On the surface, the quantum dot light conversion layer 3 is attached to the diffusion layer 2, and the optical film 5 is bonded on the quantum dot light conversion layer 3 through the adhesive layer 4 (the The material of the adhesive layer 4 is optical glue); the diffusion layer 2 is formed by coating the light diffusion material on the glass substrate 1 and curing; the light diffusion material includes the following components by weight percentage: resin 54 %, 30% of diffusion particles, 1% of silane coupling agent and 15% of diluent; the quantum dot light conversion layer 3 is dispersed in silica gel ink by quantum dots 31 and coated on the diffusion layer 2 and cured Forming.

[0049] Preferably, the light incident surface of the glass substrate 1 is provided with scattering pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com