Permanent magnet axial magnetic flux magnetic levitation motor and fan

A technology of axial magnetic flux and magnetic levitation, applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of small size, easy wear of bearings, etc., achieve high power factor, prolong service life, and reduce thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

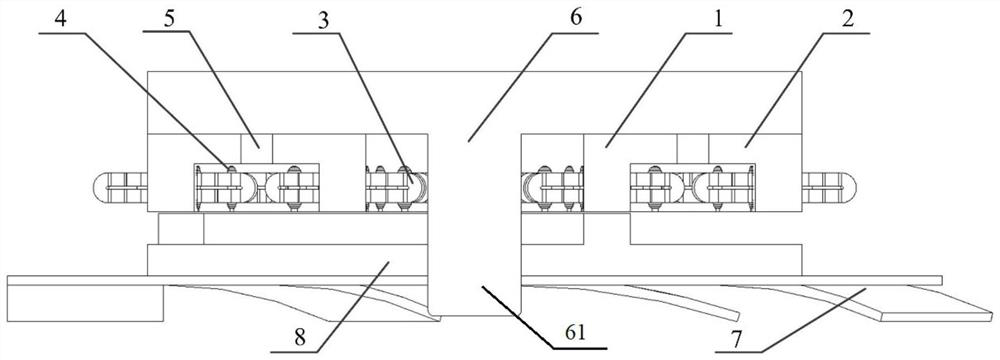

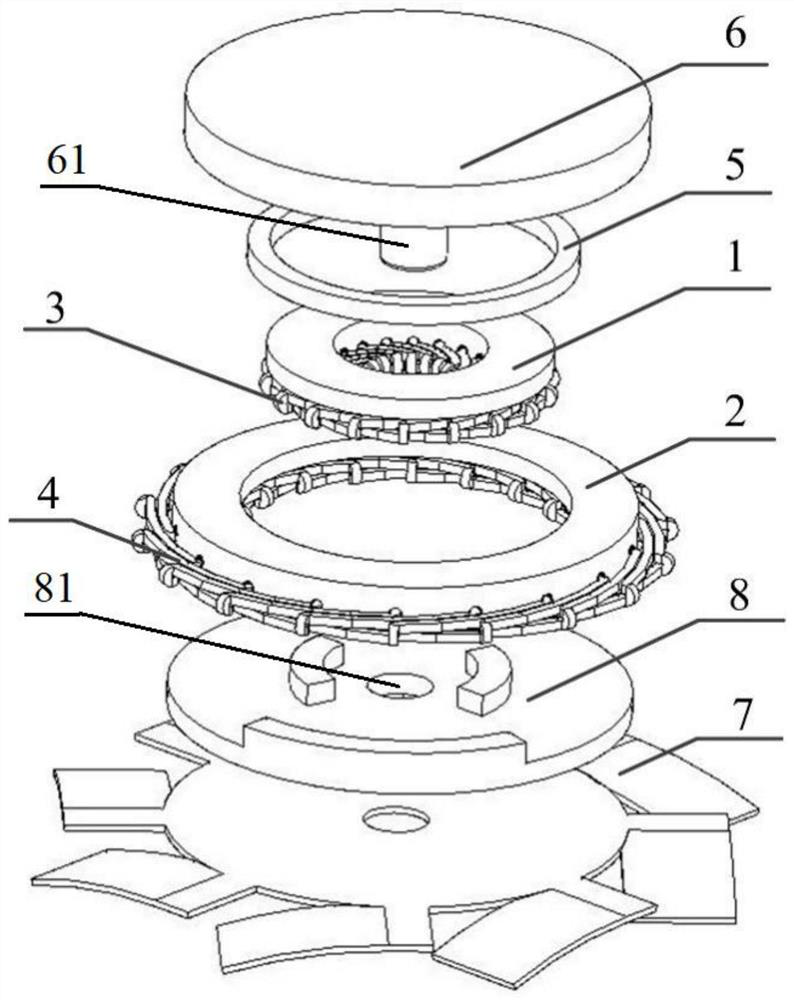

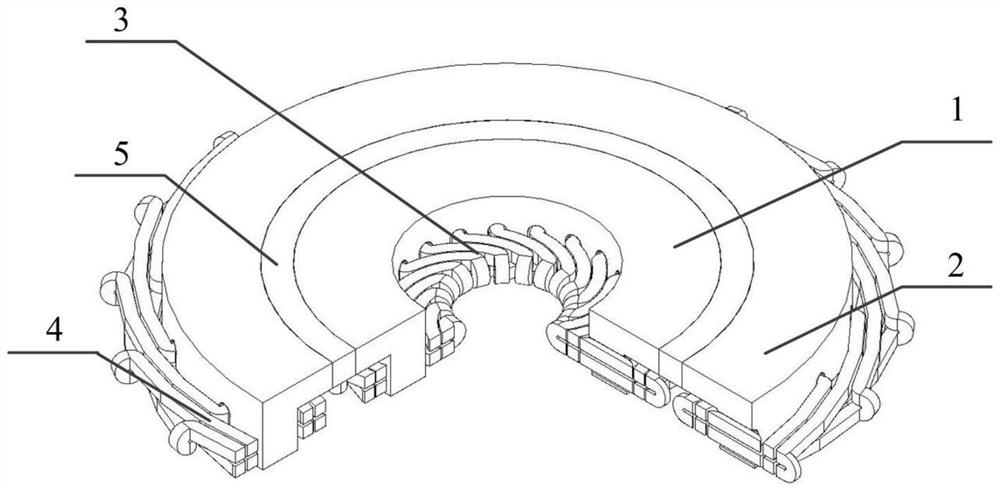

[0031] A permanent magnet axial flux magnetic levitation motor, including a stator core, a winding, a permanent magnet 5, a base 6 and a rotor core 8, the stator core includes an inner stator 1 and an outer stator 2, and the winding includes an inner winding 3 and an outer stator The winding 4 and the permanent magnet 5 are arranged between the inner stator 1 and the outer stator 2, the inner stator 1, the outer stator 2 and the permanent magnet 5 are all fixedly connected with the base 6, and the inner stator 1 and the outer stator 2 are respectively arranged on the same side. There are installation slots for inner winding 3 and outer winding 4. The inner winding 3 and outer winding 4 are respectively arranged in the installation slots for inner winding 3 and outer winding 4. The base 6 is provided with a connecting shaft 61, and the rotor core 8 passes through The bearing is rotatably connected to the connecting shaft 61 of the base 6 , the stator core and the rotor core 8 ar...

Embodiment 2

[0038] refer to Figure 1-Figure 4 , the present application also provides a fan, including the impeller 7 and the above-mentioned permanent magnet axial flux magnetic levitation motor, the impeller 7 is coaxially fixedly connected with the rotor core 8, the impeller 7 is coaxially matched with the base 6, and the impeller 7 includes a plurality of arc-shaped blades and a disk, and a plurality of arc-shaped blades are equidistantly arranged on the outer periphery of the disk. The rotor core 8 and the impeller 7 are rotationally matched with the connecting shaft 61 of the base 6 through bearings.

[0039] The present invention has the following technical effects:

[0040] 1) The present invention provides a permanent magnet axial flux magnetic levitation motor, which adopts the motor structure of permanent magnet axial flux, permanent magnet excitation and two sets of windings, and utilizes its unilateral magnetic pull and the reluctance between the stator and rotor cores The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com