Tendon suturing system for joint replacement

A joint replacement and tendon technology, applied in the field of medical surgery, can solve the problems that tendon suture products cannot be fixed in an effective position, difficult tendon suture surgery, etc., to achieve the effect of ensuring the continuity of the tendon and benefiting the health of the tendon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

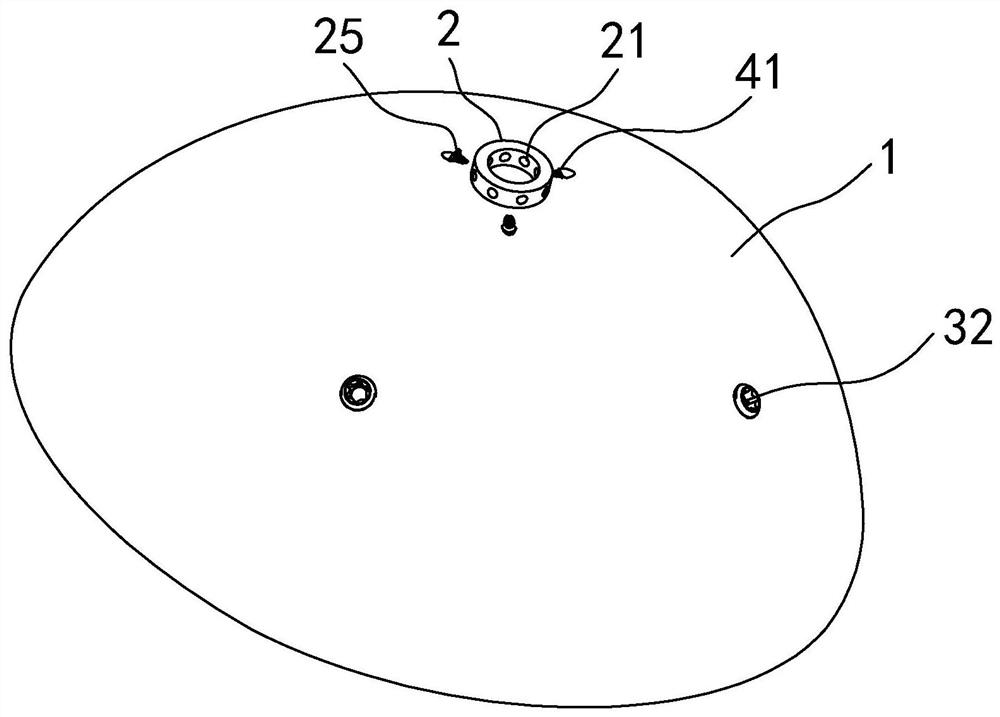

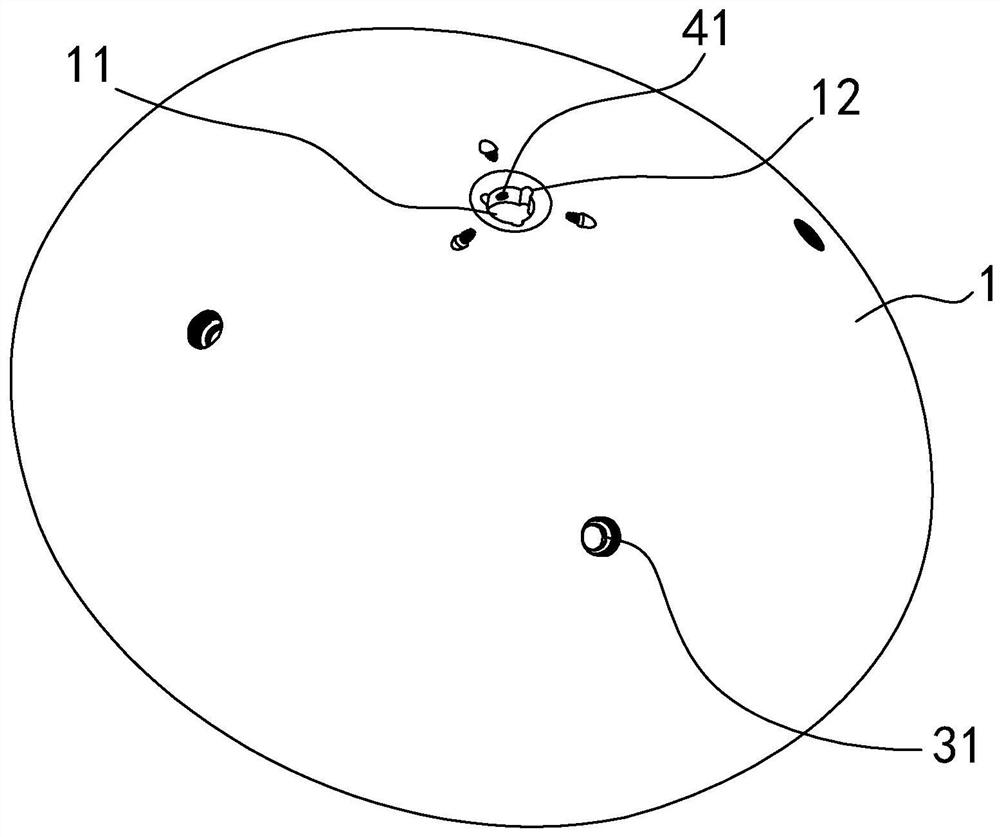

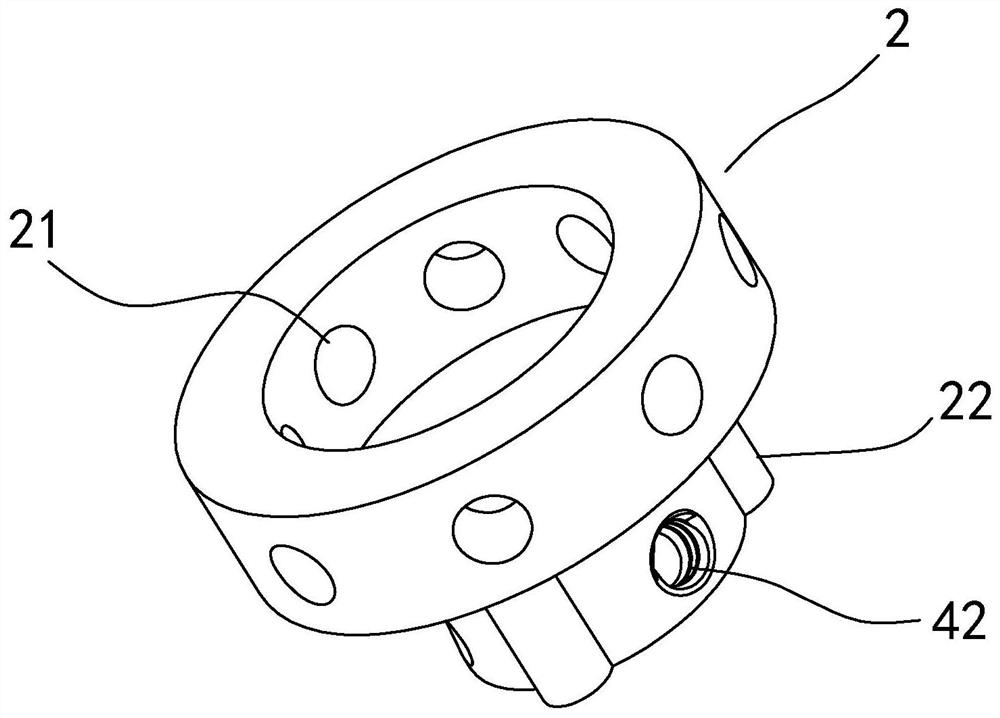

[0048] refer to Figure 1 to Figure 6 , the present invention is a kit, including a joint prosthesis 1, a stapler 2, a locking structure, a bone thread system, and a shift fork 5. The locking structure adopts thread as the main connection means. The joint prosthesis 1 has an outer convex surface, and an installation groove 11 is provided at the apex position of the outer convex surface close to the geometric shape or directly at the apex itself, and the stapler 2 is embedded in the installation groove 11 and then fixed, the stapler The upper end of the prosthesis 2 is used for binding and connecting with the artificial tendon, and the joint prosthesis 1 is connected and fixed with the external backbone through a bone thread system.

[0049] The joint prosthesis 1 can be bionically printed using 3D printing technology, so that the shape and accuracy of the product can be guaranteed, and at the same time, each threaded hole position can also be printed synchronously, and the ma...

Embodiment 2

[0055] refer to Figure 7 to Figure 9 , Embodiment 2 is basically the same as Embodiment 1, but the locking structure adopts elastic buckle as the main connection means. Specifically, the upper part of the second end of the stapler 2 is connected to the lower surface of the first end of the stapler 2 and the outer diameter of the second end is smaller than the outer diameter of the first end, thereby leaving an annular surface, A positioning column 23 extending downward is provided on the annular surface, and a positioning hole 13 matching the positioning column 23 is provided on the bottom surface of the installation groove 11. The functions of the positioning hole 13 and the positioning column 23 are the same as those in the first embodiment. Notches 12 are similar to positioning ribs 22 . And the bottom of the second end is provided with the elastic connecting cap 24 that is up big and down little down umbrella shape, and elastic connecting cap 24 is elastic material, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap