Composite ruthenium catalyst and its preparation method and application

The technology of a ruthenium catalyst and a ruthenium-carbon catalyst is applied in the field of composite ruthenium catalyst and its preparation, and can solve the problems of heavy metal ruthenium residue, difficulty in product separation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One embodiment of the present invention provides a method for preparing a composite ruthenium catalyst, comprising the steps of:

[0030] Dissolving chiral (TS-DPEN) (p-cymene) ruthenium (II) chloride in a solvent, then adding ruthenium carbon catalyst for impregnation, and evaporating to remove the solvent to obtain a composite ruthenium catalyst.

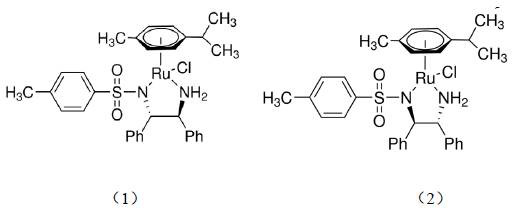

[0031] Among them, chiral (TS-DPEN) (p-cymene) ruthenium (II) chloride includes but not limited to (p-cymene) [(S,S)-TS-DPEN] ruthenium (II) chloride , whose structure is shown in formula (1), and (p-cymene)[(R,R)-TS-DPEN] ruthenium(II) chloride, whose structure is shown in formula (2).

[0032]

[0033] Studies have found that using chiral (TS-DPEN) (p-cymene) ruthenium (II) chloride directly as a catalyst for chiral synthesis has the problem of separation from chiral synthesis products, resulting in the existence of Larger content of heavy metal ruthenium remains.

[0034] Based on this, the present invention adopts ...

Embodiment 1

[0070] Under argon protection, 1 g of (p-cymene)[(S,S)-TS-DPEN]ruthenium(II) chloride was dissolved in 50 mL of dichloromethane. Then add 20 grams of 5wt% ruthenium carbon catalyst, after stirring overnight, evaporate methylene chloride at 40 degrees Celsius to prepare: 21 grams of composite ruthenium catalyst, marked as composite ruthenium catalyst A.

[0071] Wherein, in the composite ruthenium catalyst A, the mass content of (p-cymene)[(S,S)-TS-DPEN]ruthenium(II) chloride is 4.8%.

[0072] In this embodiment, the reaction time of stirring overnight is 12 hours to 14 hours, the same below.

Embodiment 2

[0074] Under argon protection, 1 g of (p-cymene)[(S,S)-TS-DPEN]ruthenium(II) chloride was dissolved in 100 mL of dichloromethane. Then add 40 grams of 3 wt % ruthenium carbon catalyst, stir overnight, and evaporate dichloromethane at 40 degrees Celsius to prepare: 41 grams of composite ruthenium catalyst, marked as composite ruthenium catalyst B.

[0075] Wherein, in the composite ruthenium catalyst B, the mass content of (p-cymene)[(S,S)-TS-DPEN]ruthenium(II) chloride is 2.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com