Liquid spraying head of plant protection unmanned aerial vehicle

A technology for planting and protecting drones and spray heads, applied in aircraft parts, spray devices, liquid spray devices, etc., can solve the problems of uneven spraying area and low service life, and achieve the effect of increasing spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

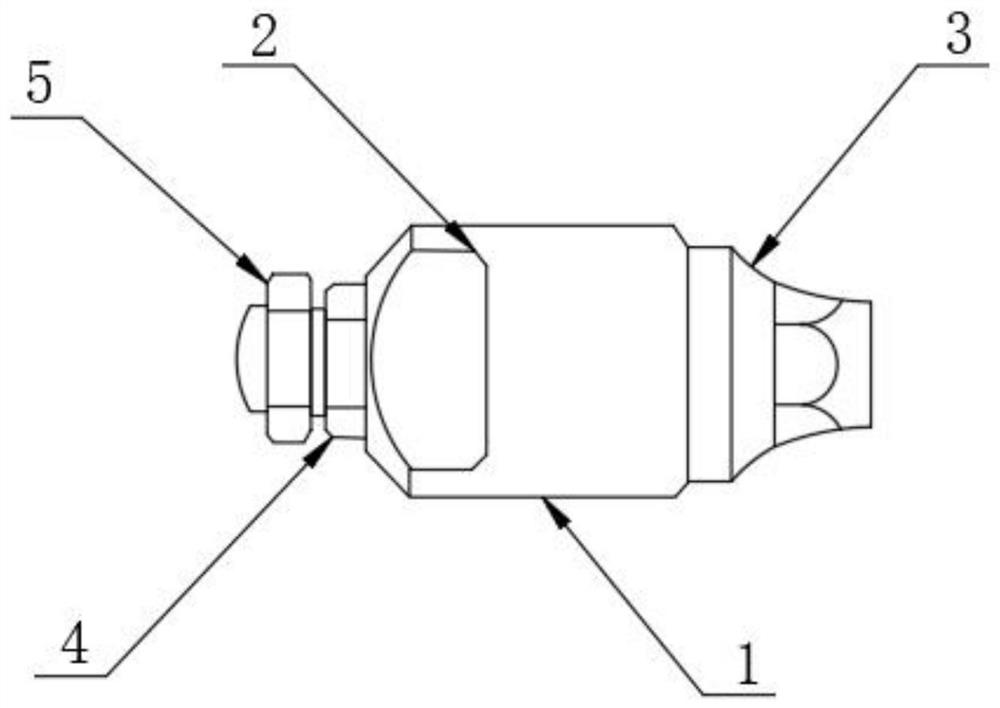

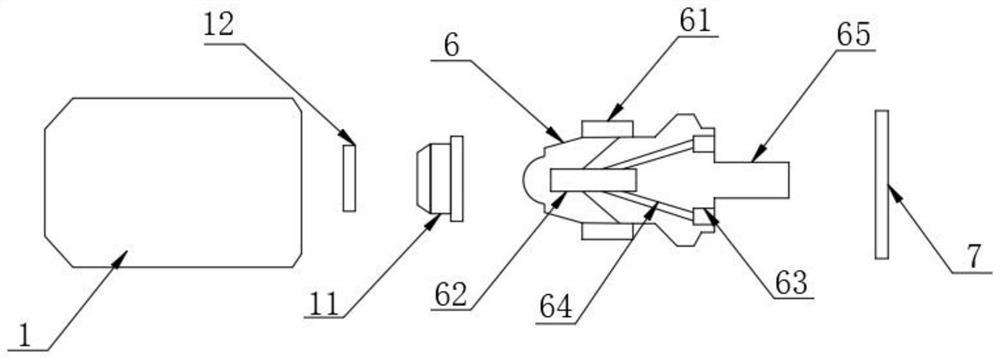

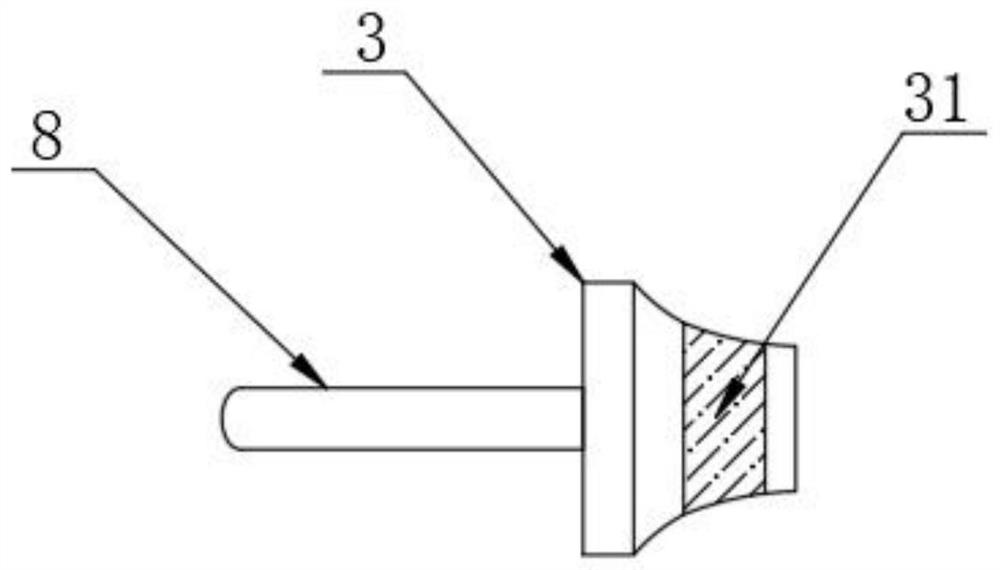

[0022] Such as Figure 1-4 The liquid spray head of a plant protection drone shown includes a liquid spray housing 1, the front surface of the liquid spray housing 1 is provided with a mounting seat 2, and one end of the liquid spray housing 1 is threadedly connected with a nozzle tail shell 3, and the spray head tail shell 3 is threaded. The other end of the liquid housing 1 is connected with a nozzle connector 4, and one side of the nozzle connector 4 is threaded with a liquid outlet 5. The liquid spray housing 1 is provided with a liquid cap 6, and the top and bottom of the liquid cap 6 are provided with reinforcements. The block 61 and the reinforcing block 61 are fixedly arranged on the top and bottom of the inner wall of the liquid spray housing 1, a mixing chamber 62 is provided inside the liquid cap 6, a sealing gasket 7 is provided on one side of the liquid cap 6, and a sealing gasket 7 is provided on the inner side of the nozzle tail case 3. Infusion tube8.

[0023]...

Embodiment 2

[0028] One side of the inner wall of the liquid cap 6 is provided with an air valve 63, the air valve 63 is arranged on the top and bottom of the infusion tube 8 and the inside of the air valve 63 is provided with a vent pipe 64, the vent pipe 64 communicates with the mixing chamber 62, and the air valve 63 is connected to the air pump on the outside After the air is transported into the mixing chamber 62 to mix with the liquid medicine, the high-pressure gas drives the liquid medicine to spray out to the outside, and the liquid medicine and gas are uniformly and stably transmitted.

[0029] One end of the liquid cap 6 is provided with a slot 65, the infusion tube 8 is plugged into the slot 65, and the sealing gasket 7 is arranged around the outside of the slot 65, and the sealing gasket 7 ensures that the internal medicinal liquid does not leak.

[0030] The specific real-time method of this embodiment: the medicinal liquid enters the slot 65 through the infusion tube 8, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com