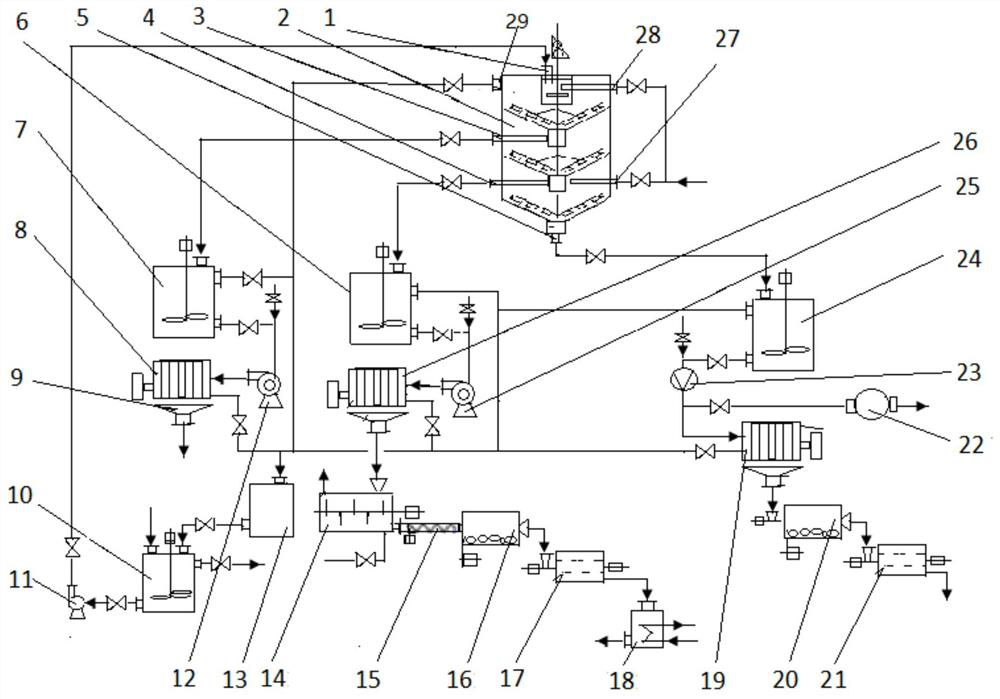

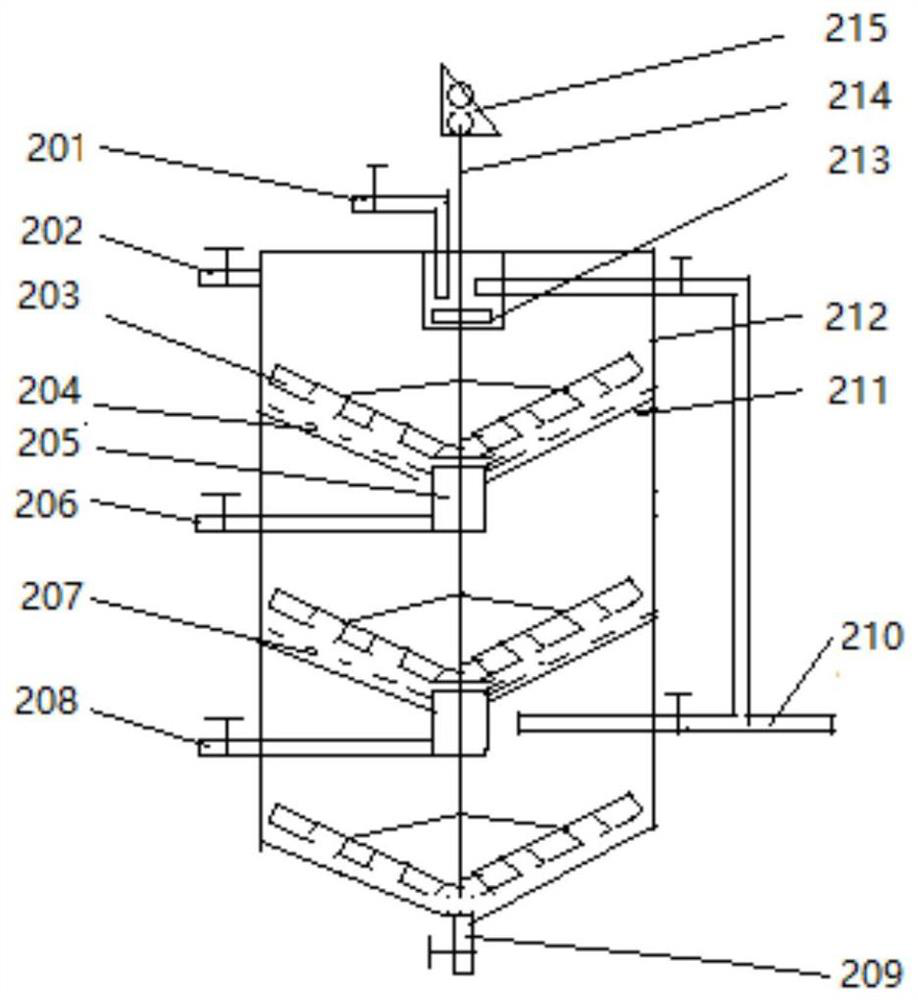

Automatic grading treatment application device for high-content calcium sulfate salty mud

An automatic grading and calcium sulfate technology, which is applied in the direction of filtration separation, separation method, dispersion particle separation, etc., to achieve the effect of protecting the environment, good use effect and reducing desulfurization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: When using Taishan salinized salt mud as a raw material to carry out salt mud washing and fractionation, the initial components of the salt mud after testing are as follows: H 2 O 29.77%; Ca 2+ 15.64%; Mg 2+ 3.17%; SO 4 2- 23.74%; Cl - 4.91%; CO 3 2- 4.45%.

[0039] Converted to compound: H 2 O 29.77%; NaCl 8.09%; CaSO 4 2H 2 O 41.86%; CaCO 3 7.42%; Ca(OH) 2 5.41%; Mg(OH) 2 7.57%.

[0040] When 200-mesh and 400-mesh screens are used in the mud washing tank 2, only the mesh number of the screen is changed, and when the others remain unchanged, the component content after fractionation is as follows:

[0041] When using a 200 mesh sieve, the components of the sieve (dry basis) are as follows: CaSO 4 1 / 2H 2 O 72.19%; CaCO 3 20.43%; Ca(OH) 2 3.09%; Mg(OH) 2 4.23%.

[0042] When using a 400 mesh sieve, the components of the sieve (dry basis) are as follows: CaSO 4 1 / 2H 2 O 65.92%; CaCO 3 : 22.85%; Ca(OH) 2 : 6.79%; Mg(OH) 2 : 4.63%. ...

Embodiment 2

[0044] Example 2: The Taishan salinization salt mud in Example 1 was used as a raw material to carry out the salt mud washing and fractionation test, and the results are as follows.

[0045] When 100-mesh and 450-mesh screens are used in the mud washing tank 2, only the mesh number of the screen is changed, and when the others remain unchanged, the component content after fractionation is as follows:

[0046] When the primary sieve uses a 100-mesh sieve, the components of the sieve (dry basis) are as follows: CaSO 4 1 / 2H 2 O 76.76%; CaCO 3 18.89%; Ca(OH) 2 1.18%; Mg(OH) 2 2.93%;

[0047] When using a secondary sieve with a 450 mesh sieve, the components of the sieve (dry basis) are as follows: CaSO 4 1 / 2H 2 O 67.05%; CaCO 3 21.81%; Ca(OH) 2 6.53%; Mg(OH) 2 4.6%;

[0048] In this example, the semi-dry desulfurizer (dry basis) obtained after the 450-mesh sieve slurry sedimentation treatment is as follows: CaSO 4 2H 2 O 39.78%; CaCO 3 : 23.26%; Ca(OH) 2 : 4.92%;...

Embodiment 3

[0049] Example 3: The Taishan salinization salt mud in Example 1 was used as the raw material to carry out the salt mud washing and fractionation test, and the results are as follows.

[0050] When 80-mesh and 325-mesh screens are used in the mud washing tank 2, only the mesh number of the screen is changed, and when the others remain unchanged, the component content after fractionation and separation:

[0051] When the primary sieve uses a 80-mesh sieve, the oversize components (dry basis) are as follows: CaSO 4 2H 2 O 86.57%; CaCO 3 6.14%; Ca(OH) 2 4.32%; Mg(OH) 2 0.82%;

[0052] When using a secondary sieve with a 325 mesh sieve, the components of the sieve (dry basis) are as follows: CaSO 4 1 / 2H 2 O7 1.79%; CaCO 3 14.60%; Ca(OH) 2 9.24%; Mg(OH) 2 4.62%;

[0053] In this example, the semi-dry desulfurizer (dry basis) obtained after the 325-mesh sieve slurry sedimentation treatment is as follows: CaSO 4 2H 2 O 53.24%; CaCO 3 : 15.76%; Ca(OH) 2 : 3.99%; Mg(OH)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com