Clamping workbench for welding machining of fireproof door plate body

A door panel body and workbench technology, which is applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of endangering the health of workers, poor use effect, time-consuming and labor-intensive, etc., so that the fixing process is simple and convenient, and the body is guaranteed Health, the effect of improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

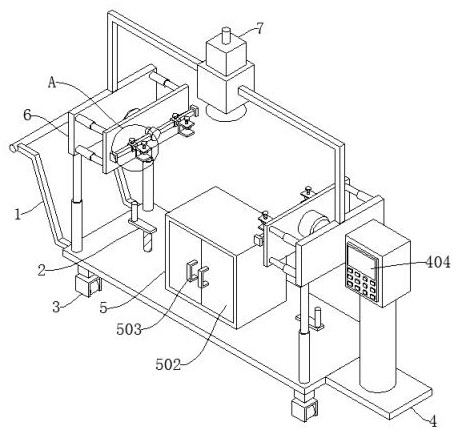

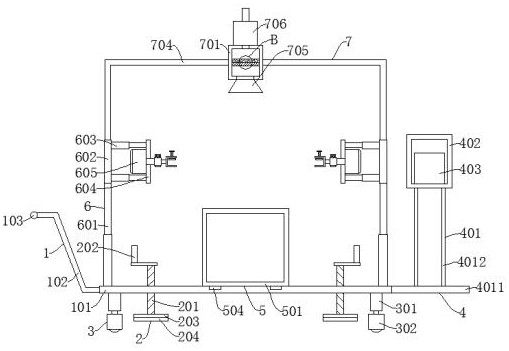

[0045] like figure 1 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, a clamping workbench for welding and processing of fire door panels includes a push-pull mechanism 1, a fixed mechanism 2, a moving mechanism 3, and a control mechanism 4 for controlling the operation of the device. The push-pull mechanism 1 is equipped with a fixed mechanism 2. A moving mechanism 3 is installed below the mechanism 1, and a control mechanism 4 is arranged on the side of the push-pull mechanism 1, which also includes a storage mechanism 5, an overturning mechanism 6, and a purification mechanism 7. The storage mechanism 5 is arranged above the push-pull mechanism 1, and the overturning mechanism 6 is arranged on The fixing mechanism 2 is away from the side of the storage mechanism 5, and the purification mechanism 7 is fixed above the turning mechanism 6;

[0046] Push-pull mechanism 1 comprises horizontal plate 101, connecting rod 102, push-pull rod 103, and connectin...

Embodiment 2

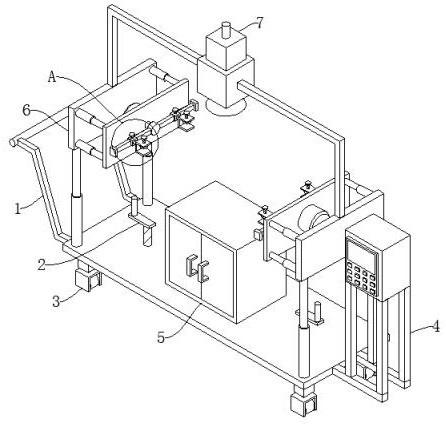

[0056] like figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the side plate 4011 and the support cylinder 4012 are replaced by a cross bar 4013 and a vertical bar 4014. During the operation of the device, the cross bar 4013 and the vertical bar 4014 cooperate to control The box 402 is supported and fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com