Carrier manipulator for front shell of Bluetooth headset charging box

A Bluetooth earphone and charging box technology, applied in the field of manipulators, can solve the problems of low accuracy and low assembly efficiency, and achieve high assembly efficiency, prevent deviation, and good assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

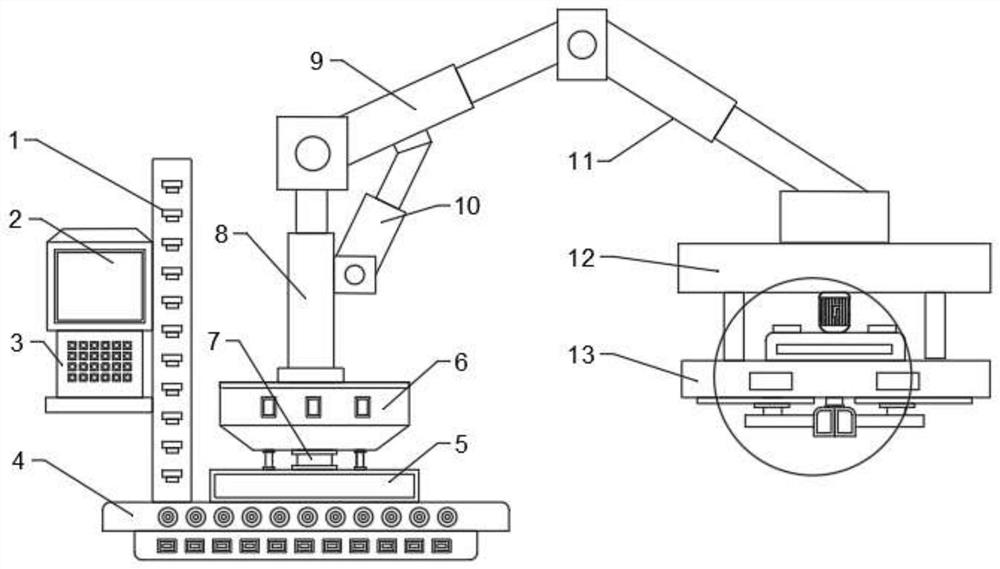

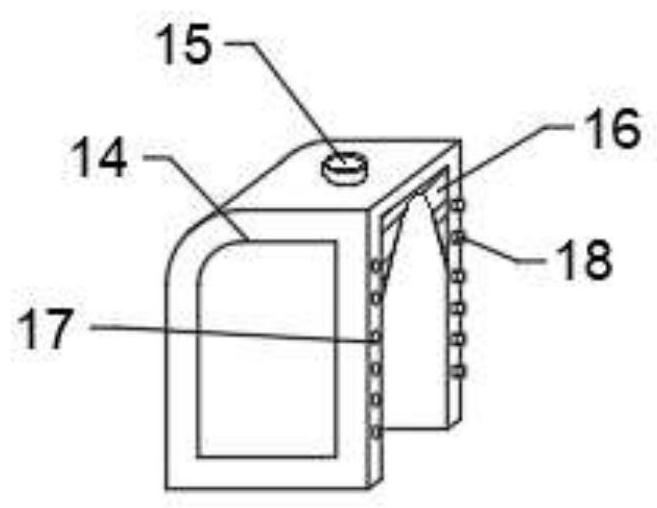

Embodiment 1

[0022] see Figure 1~4 , in an embodiment of the present invention, a carrier manipulator for the front case of a Bluetooth earphone charging box, including a mounting plate 1; a display screen 2 and an operation panel 3 are installed on the mounting plate 1; the mounting plate 1 is mounted on a base 4 The top of the base 4 is equipped with a driving box 5; the driving box 5 is connected to the installation box 6 through a rotating mechanism; a No. 1 hydraulic rod 8 is installed on the described installation box 6; the No. 1 hydraulic rod 8 is hinged to two One end of No. 9 hydraulic rod 9; the other end of No. 2 hydraulic rod 9 is hinged No. 4 hydraulic rod 11; No. 3 hydraulic rod 10 is hinged between No. 1 hydraulic rod 8 and No. 2 hydraulic rod 9; A working plate 12 is installed on the bottom of the hydraulic rod 11; a working device 13 is installed on the bottom of the working plate 12.

[0023] Further, the rotating mechanism includes a servo motor; the servo motor is co...

Embodiment 2

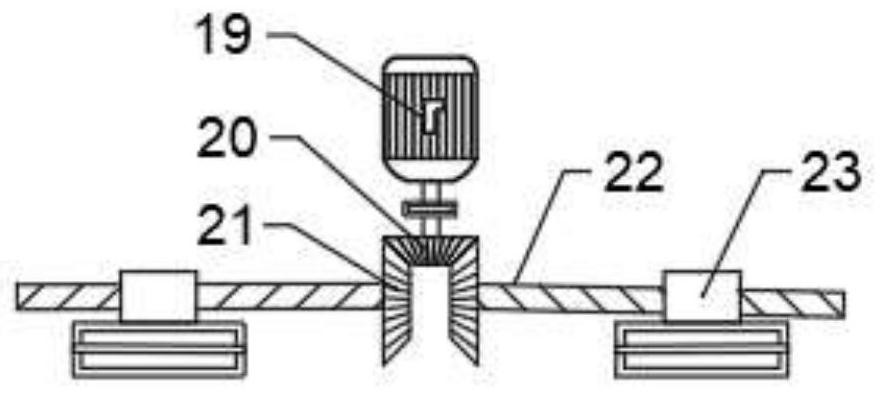

[0029] see figure 2 , the bottom of the installation box 6 is fixedly equipped with a slide bar; the slide bar is at least evenly provided with four; the bottom end of the slide bar is provided with a slider; the bottom end of the slide block is provided with a ball; The top of the drive box 5 has a circular track corresponding to the slide block; the inner bottom of the circular track is provided with a ball groove corresponding to the ball; through the setting of the slide bar, balls, slider, circular track and ball groove, the working device 13 can be rotated stably , to prevent assembly deviation and ensure assembly accuracy.

[0030]The working principle of the present invention is: through the setting of servomotor, gearbox, gear and rotating column 7, can rotate work implement 13, convenient to use; The setting of the No. 4 hydraulic rod 11 can adjust the air position of the operation panel 3, which is convenient for assembly; through the mutual cooperation of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com