Treatment device for bed board paint spraying

A processing device and bed board technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of reducing the effect of spray painting treatment and secondary adhesion, so as to improve the effect of grinding treatment, improve stability, The effect of improving the sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

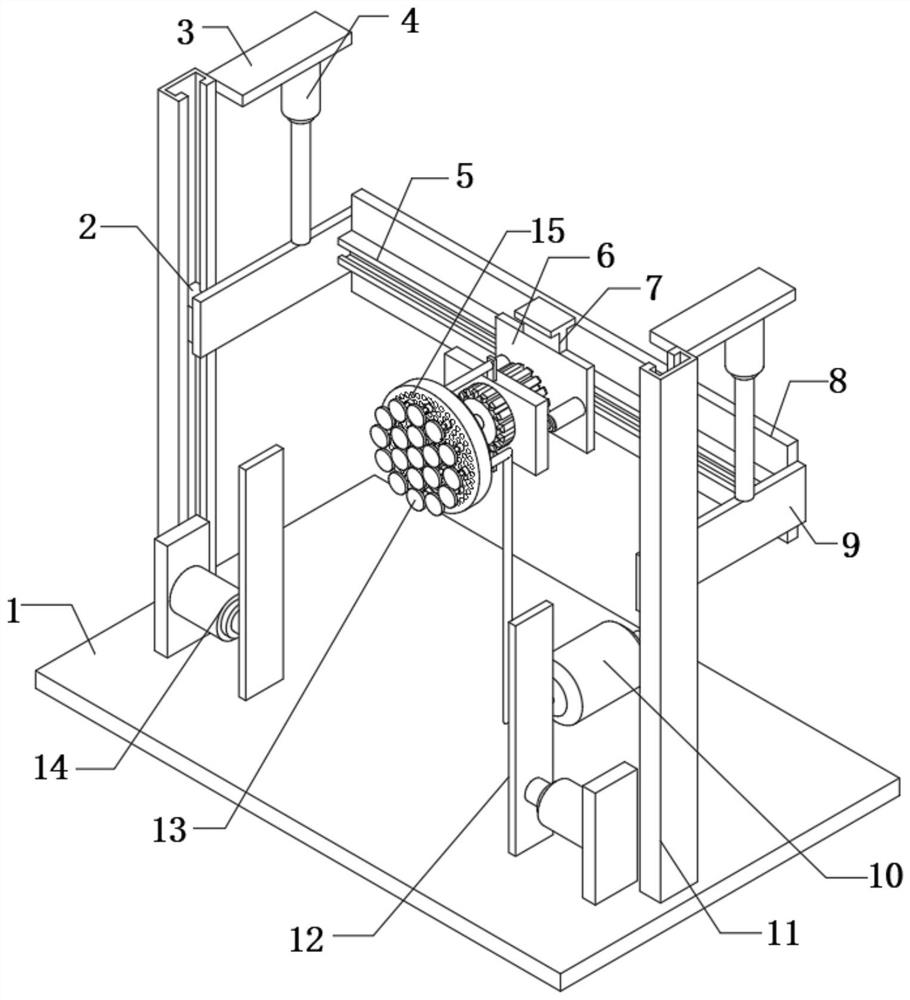

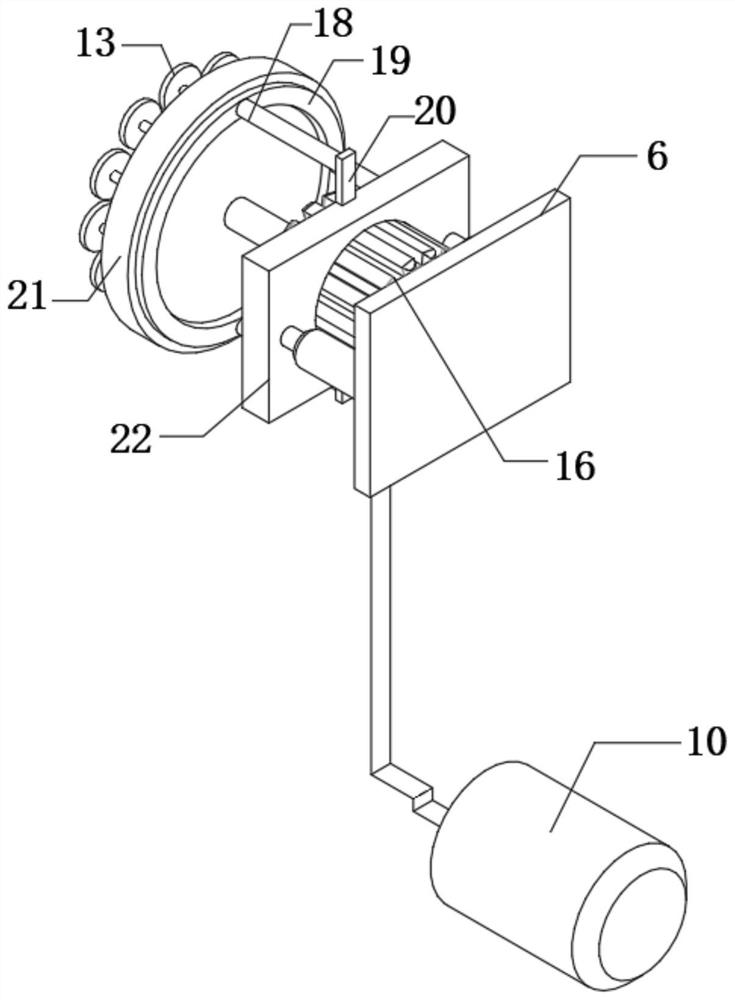

[0023] refer to Figure 1-3 , a treatment device for spraying bed boards, comprising a bottom plate 1 and an adjusting plate 6, the two ends of one side of the outer wall of the adjusting plate 6 are fixedly connected with No. 2 hydraulic cylinders 17, and the other ends of the two No. 2 hydraulic cylinders 17 are fixedly connected with With the same motor plate 22, the inner wall of the motor plate 22 is fixedly connected with a motor 16, and the output shaft of the motor 16 is fixedly connected with a rotating shaft through a coupling, and the other end of the rotating shaft is fixedly connected with a hollow plate 21, and the hollow plate 21 faces the side of the motor 16. The outer wall is provided with an annular connecting hole, and the inner wall of the annular connecting hole is connected with an air pipe 19 through a bearing, and the outer wall of the air pipe 19 is fixedly connected with two connecting rods 18, and the other ends of the two connecting rods 18 are fixe...

Embodiment 2

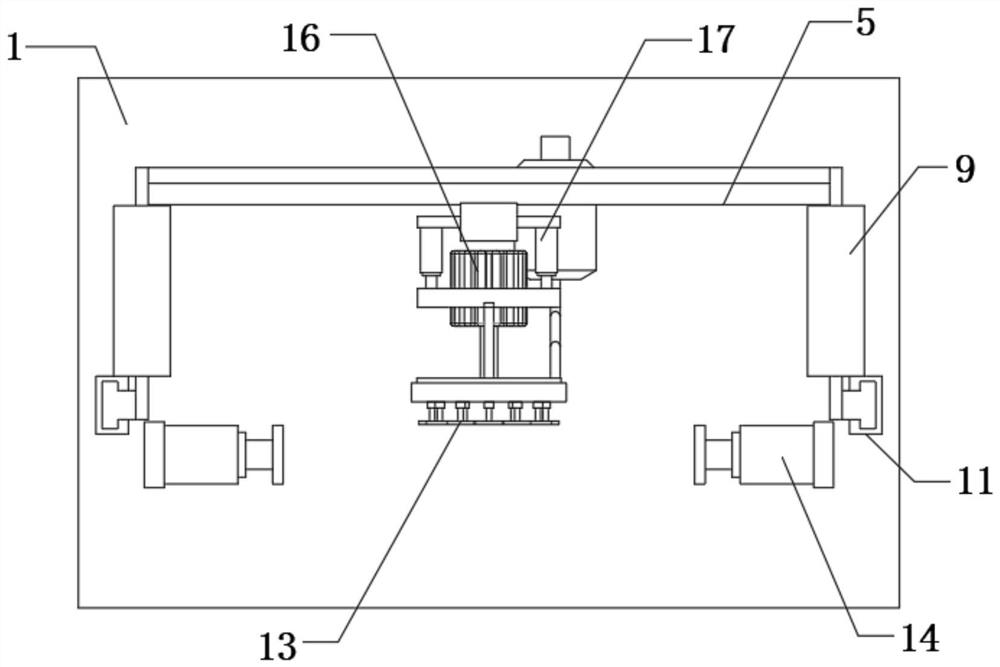

[0031] refer to Figure 4 , a treatment device for spraying bed boards, comprising a bottom plate 1 and an adjusting plate 6, the two ends of one side of the outer wall of the adjusting plate 6 are fixedly connected with No. 2 hydraulic cylinders 17, and the other ends of the two No. 2 hydraulic cylinders 17 are fixedly connected with With the same motor plate 22, the inner wall of the motor plate 22 is fixedly connected with a motor 16, and the output shaft of the motor 16 is fixedly connected with a rotating shaft through a coupling, and the other end of the rotating shaft is fixedly connected with a hollow plate 21, and the hollow plate 21 faces the side of the motor 16. The outer wall is provided with an annular connecting hole, and the inner wall of the annular connecting hole is connected with an air pipe 19 through a bearing, and the outer wall of the air pipe 19 is fixedly connected with two connecting rods 18, and the other ends of the two connecting rods 18 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com