Full-automatic cement flue machine production line device

A flue machine and production line technology, used in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive specifications, low efficiency, increase labor costs and labor intensity, etc., to reduce the degree of scrap, Improve work efficiency and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

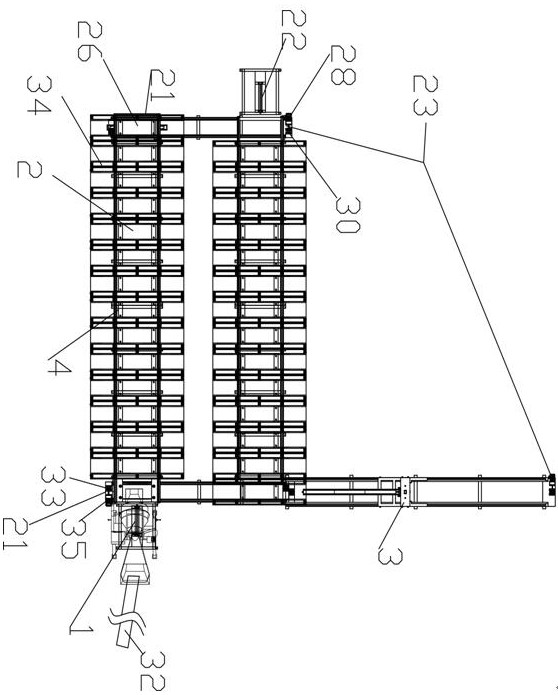

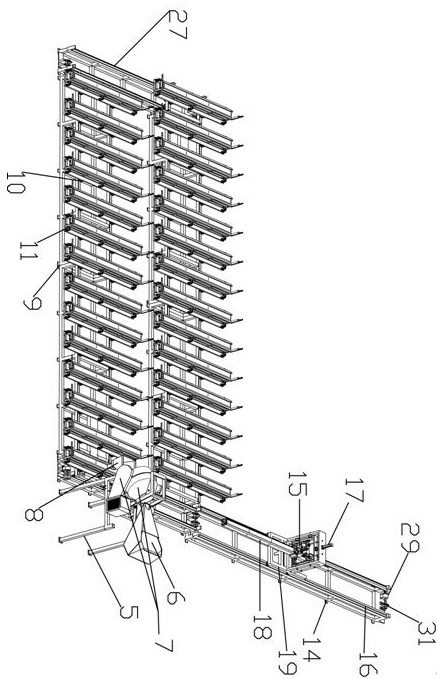

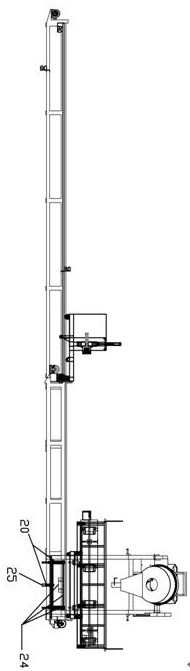

[0023] Such as Figure 1-4As shown, the technical solution adopted by the present invention to solve the above technical problems is: the technical solution adopted by the present invention to solve the above technical problems is: a fully automatic cement flue machine production line device, including automatic feeder mixer grouting mechanism assembly 1 , flue mold assembly 2, demoulding and clamping mechanism assembly 3, vibration mechanism assembly 20, transition circulation track 4, transition traction mechanism assembly 21, mold pushing cylinder 22 and motor assembly 23, said flue mold assembly 2 is arranged on the mold On the group circulation track 4, the automatic feeder mixer grouting mechanism assembly 1 is arranged above the transition circulation track 4, the demoulding and clamping mechanism component 3 is connected with the transition circulation track 4, and the demoulding and clamping mechanism 3 Located on the side of the grouting mechanism assembly 1 of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com