Injection mold of automobile eight-way valve body

A technology of injection molds and eight-way valves, which is applied to home appliances, other home appliances, and household components, can solve problems such as machine failures, increased production costs due to processing errors, and inclinations that do not meet requirements, so as to ensure product quality. Increased precision, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

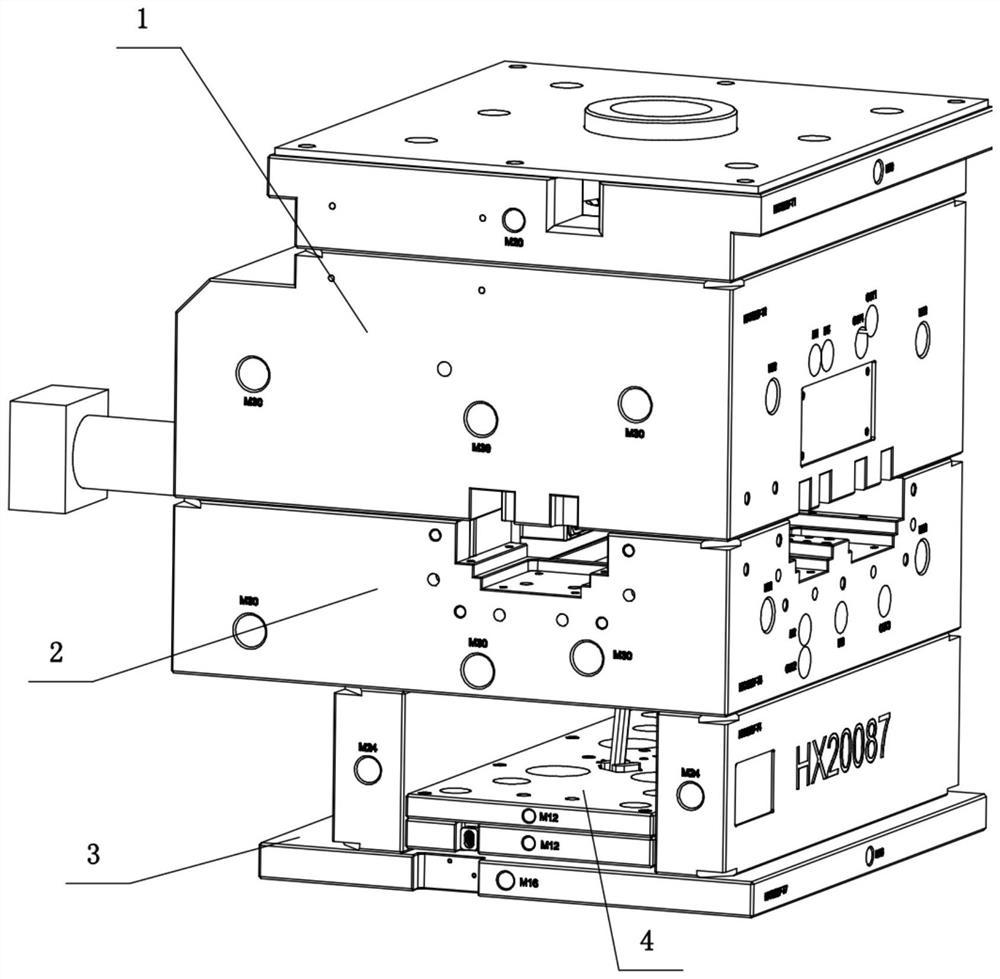

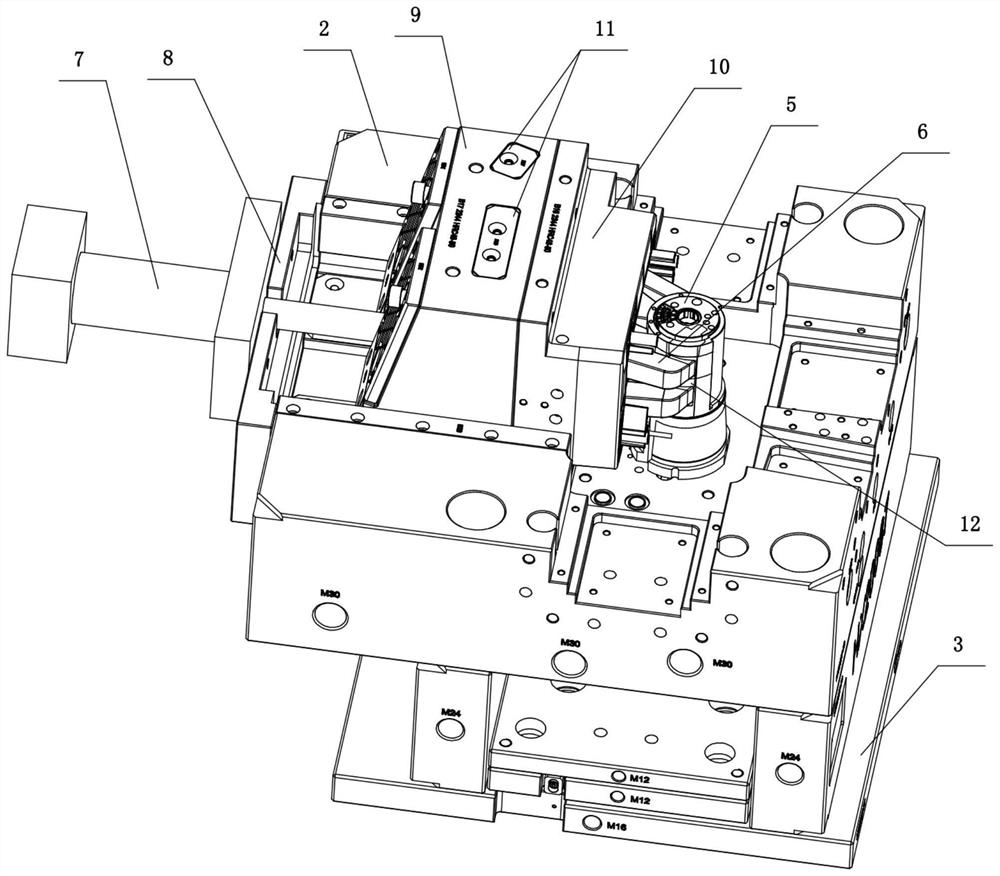

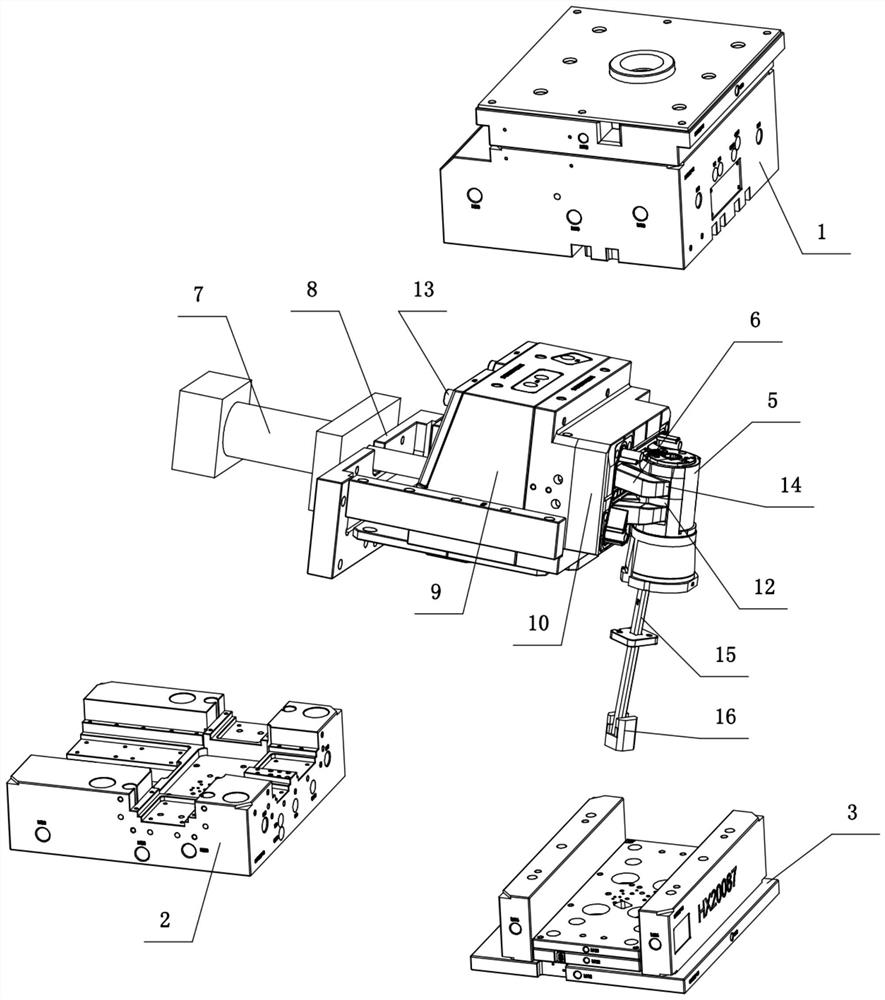

[0027] to combine Figure 1 to Figure 7 As can be seen from the structural schematic diagram of the injection mold of the automobile eight-way valve body of the present invention, it includes a fixed mold assembly 1, a movable mold assembly 2 and an ejection mechanism, and after the fixed mold assembly 1 and the movable mold assembly 2 are molded A forming mold cavity is formed, and the ejector mechanism is located below the movable mold assembly 2 . The injection mold also includes a mold core 5 for forming the central through hole of the eight-way valve body of an automobile and a core-pulling rod 6 for forming a plurality of oblique holes of the eight-way valve body of the automobile; Core-pulling device, the inclined top device is arranged vertically, the upper end of the inclined top device is connected with the mold core 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com