Storage equipment for polypropylene

A storage device, polypropylene technology, applied in the direction of internal accessories, external accessories, etc., can solve the problems of polyethylene particles sticking together, and polypropylene particles being too late to dissipate heat completely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

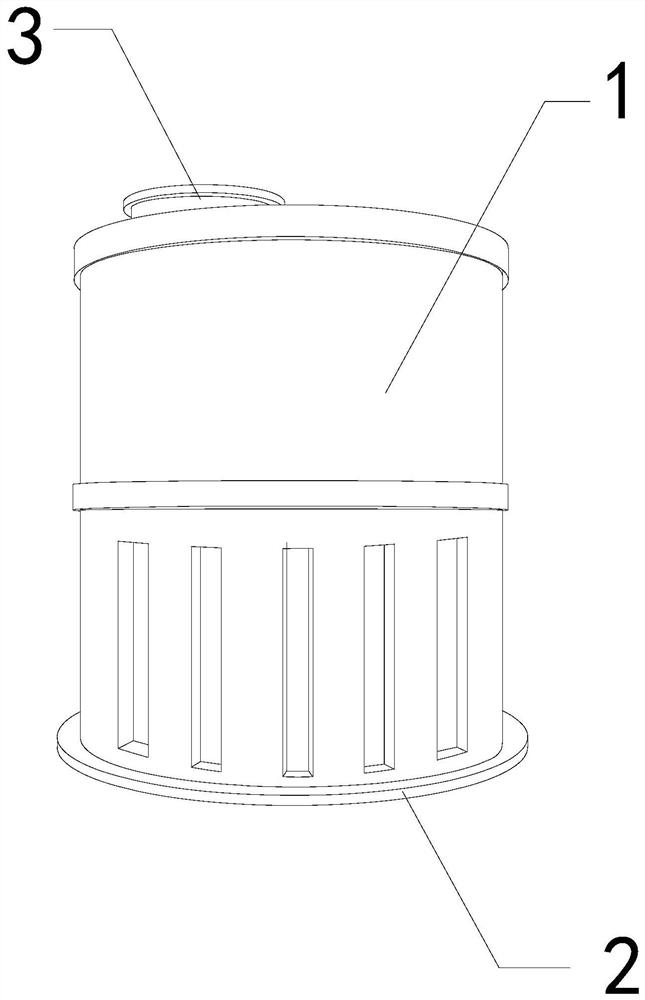

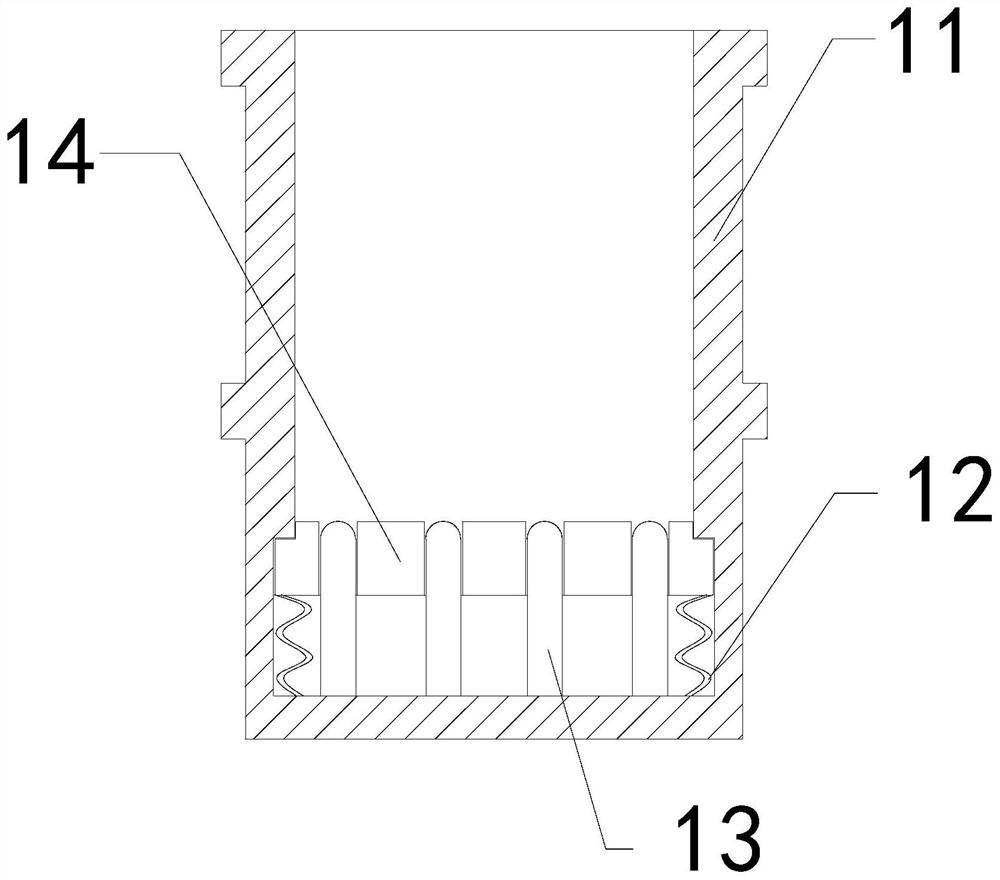

[0027] The invention provides a storage device for polypropylene, the structure of which includes a storage bucket 1, a base 2, and a feed port 3. The feed port 3 is embedded in the upper end of the storage bucket 1. phase welding; the storage bucket 1 includes an outer frame 11, an elastic strip 12, an upper extension plate 13, and a contraction plate 14. The bottom of 13 is embedded and connected with the bottom of the inner wall of the outer frame 11 , and the upper extension plate 13 is in clearance fit with the contraction plate 14 , and the contraction plate 14 is movably engaged with the outer frame 11 .

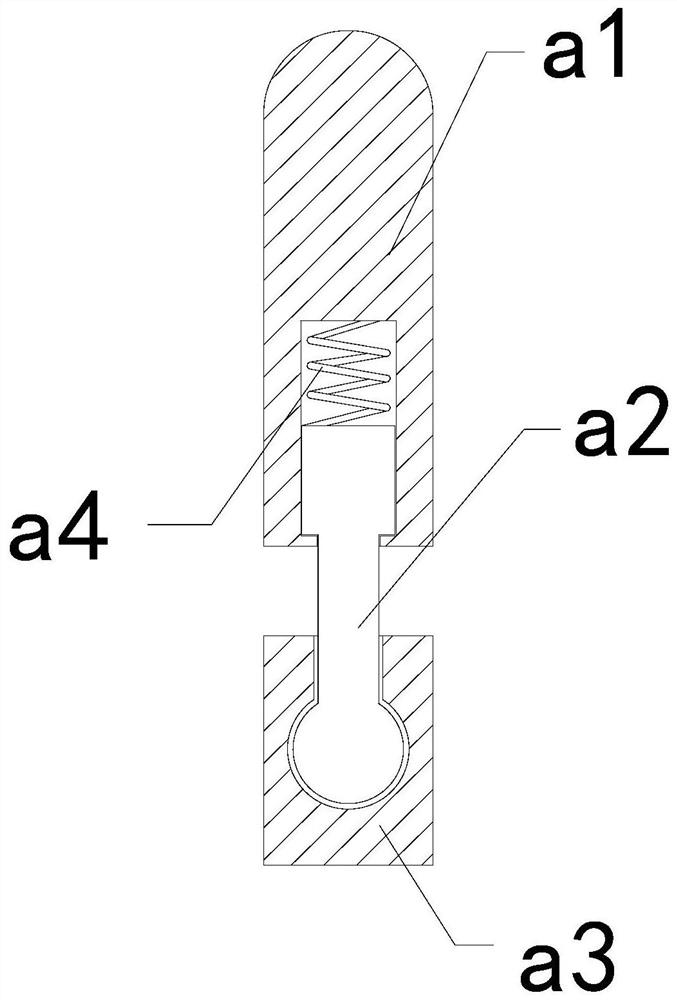

[0028] Wherein, the upper extension plate 13 includes a contact plate a1, a middle solid bar a2, a bottom plate a3, and a booster bar a4, the contact plate a1 is connected with the middle solid bar a2, and the middle solid bar a2 is movable with the bottom plate a3 Together, the booster bar a4 is installed bet...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the connecting plate a11 includes a receiving plate c1, a heat sink c2, and a heat conduction mechanism c3. The heat sink c2 and the heat conduction mechanism c3 are an integrated structure, and the heat conduction mechanism c3 is embedded in the inner position of the receiving plate c1. The receiving plate c1 is made of copper metal with strong thermal conductivity, and the heat inside the object can be introduced into the interior of the heat conducting mechanism c3 through c4.

[0036] Wherein, the heat conduction mechanism c3 includes a frame c31, an upper sliding ball c32, an interference plate c33, and a reverse push bar c34. The upper slide ball c32 is installed in the inner position of the frame c31, and the interference plate c33 is embedded in the reverse push bar. The bottom position of c34, the reverse push bar c34 is connected with the upper end of the inner wall of the frame c31, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com