Preparation device for producing low-dimensional magnetic material and using method of preparation device

A technology of magnetic material and preparation device, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of raw material waste, waste, and easily broken containers, and achieve the effect of improving efficiency, increasing bearing capacity, and avoiding chain cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

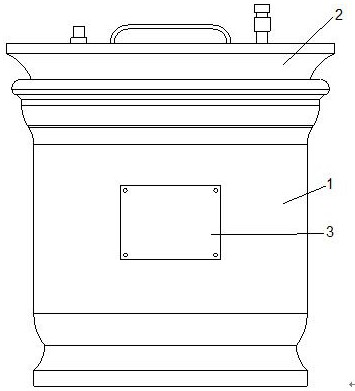

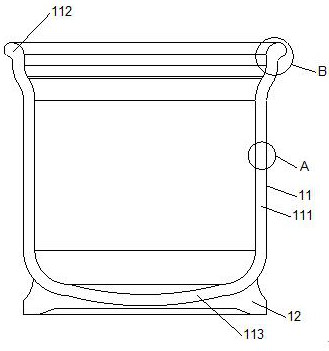

[0042] Such as figure 1 , figure 2 , Figure 5 As shown, the present invention provides a preparation device for the production of low-dimensional magnetic materials and a method for using the same, including a container mechanism 1, a nameplate 3 is provided on the outer wall of the container mechanism 1, and a separator 2 is provided at the upper end of the container mechanism 1. The container mechanism 1 includes a tank body 11, the lower end surface of the tank body 11 is fixedly welded with a placement member 12, the tank body 11 includes an intermediate tank body 111, the intermediate tank body 111 is cylindrical, and the upper port of the intermediate tank body 111 There is a top tank mouth 112 at the bottom of the middle tank body 111, and a tank bottom 113 is arranged at the lower port of the middle tank body 111. The component 12 is fixedly welded on the outer surface of the tank bottom 113. The isolator 2 includes a sealing component 21. A top component 22 is arr...

Embodiment 2

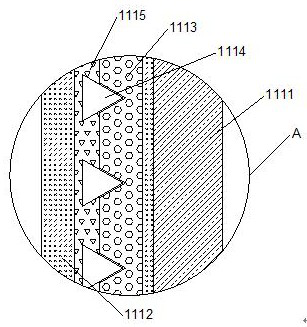

[0045] Such as Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the intermediate tank body 111 includes a steel tank body 1111, the inner wall of the steel tank body 1111 is provided with a tank body ceramic wall 1112, and the tank body ceramic wall The inside of the wall 1112 is provided with a prefabricated base 1113, and a side of the prefabricated base 1113 away from the steel tank 1111 is embedded with a No. 1 lining member 1114, and the inner side of the No. 1 lining member 1114 is fixed on the sealing base 1115 inside, the sealing base 1115 is attached to the prefabricated base 1113, and the sealing base 1115 is set inside the ceramic wall 1112 of the tank body, the top tank mouth 112 includes a steel structure lining 1121, and the steel structure lining 1121 It is arranged in the shape of a funnel at the upper port of the steel tank body 1111. The upper port of the steel structure lining 1121 is provided with a ta...

Embodiment 3

[0048] Such as Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the sealing member 21 includes a No. 2 lining member 211, and the lower port of the No. 2 lining member 211 is a fitting structure 212, and the fitting structure 212 is in the shape of The steel lining 1121 fits into a funnel shape, and the outer side of the fitting structure 212 is sealed and bonded with a sealing veneer 214. The upper end of the second lining member 211 is a compression structure 213, and the compression structure 213 is in the shape of a spherical arc plate. The upper side of the compression structure 213 is fixedly bonded to the top member 22, and the inner side walls of the No. Recessed design, the one-way flow suppression member 24 includes a cavity member 241, the upper port of the cavity member 241 is provided with a flow suppression assembly 242, the flow suppression assembly 242 is provided with a reset elastic member 243, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com