Hoisting method of offshore crane

A hoisting method and crane technology, which are applied to the testing and measuring devices of cranes, machines/structural components, etc., can solve the problems of increasing assembly time and cost, difficulty in precise adjustment, and large volume of components, and achieve convenient operation and high precision. , The effect of hoisting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

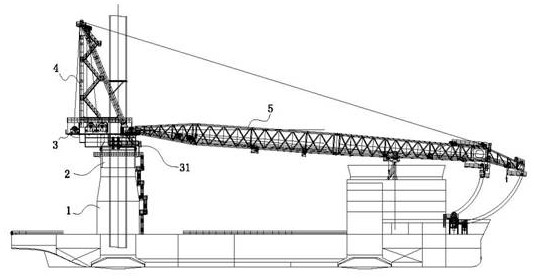

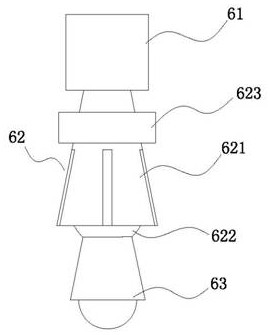

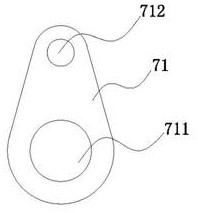

[0069] Such as Figure 1-Figure 12 As shown, a hoisting method of an offshore crane includes hoisting the base 1, the slewing platform assembly 2, the tripod 3 and the boom 4

[0070] The hoisting of the base includes the following steps:

[0071] (1) Take any three lifting points that are not on the same plane to obtain the center of gravity of the base. The specific steps are:

[0072] (1.1) Take any point on the base as a lifting point. After being lifted by a crane, attach the magnetic laser light to the base directly below the lifting point, and adjust the light output direction of the magnetic laser light so that the light output direction is vertical. level;

[0073] (1.2) Take another point on the base as a lifting point. After being lifted by a crane, another magnetic laser light is adsorbed on the base directly below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com