Fabricated building and design method thereof

A prefabricated and architectural technology, applied in the direction of buildings, building components, building structures, etc., can solve problems such as earthquake resistance and wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

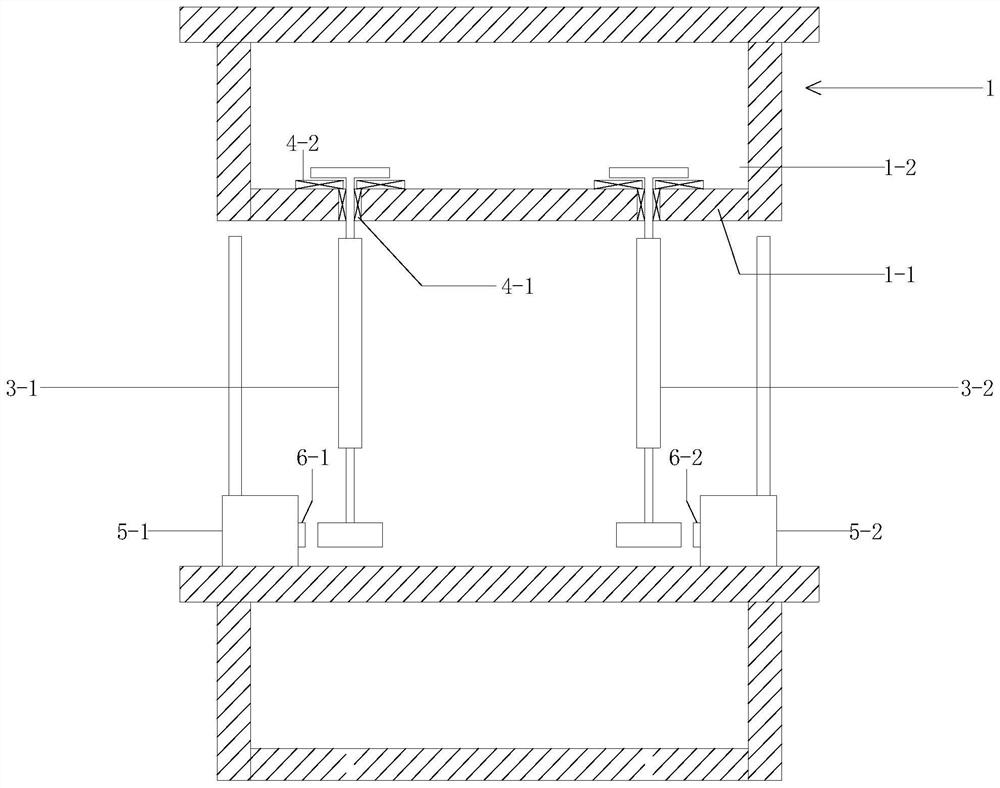

[0074] A quick assembly wall structure, which is arranged between the upper box girder 1 (belonging to the necessary technical features) and the lower box girder 2 (the lower box girder 2 can also adopt other structural forms);

[0075] It includes: a first rotating assembly 3-1, a second rotating assembly 3-2 (which is a necessary technical feature), a first base block 7-1, a second base block 7-2, and a box;

[0076] Arranged in order from left to right: the first base block 7-1, the first rotating assembly 3-1, the second rotating assembly 3-2, and the second base block 7-2;

[0077] Wherein, the box includes: a first side wall 5-1, a second side wall 5-2, and a viscous damping fluid inside the box; the first side wall 5-1, the second side wall of the wall 5-2 are parallel to each other and extend along the length direction of the beam;

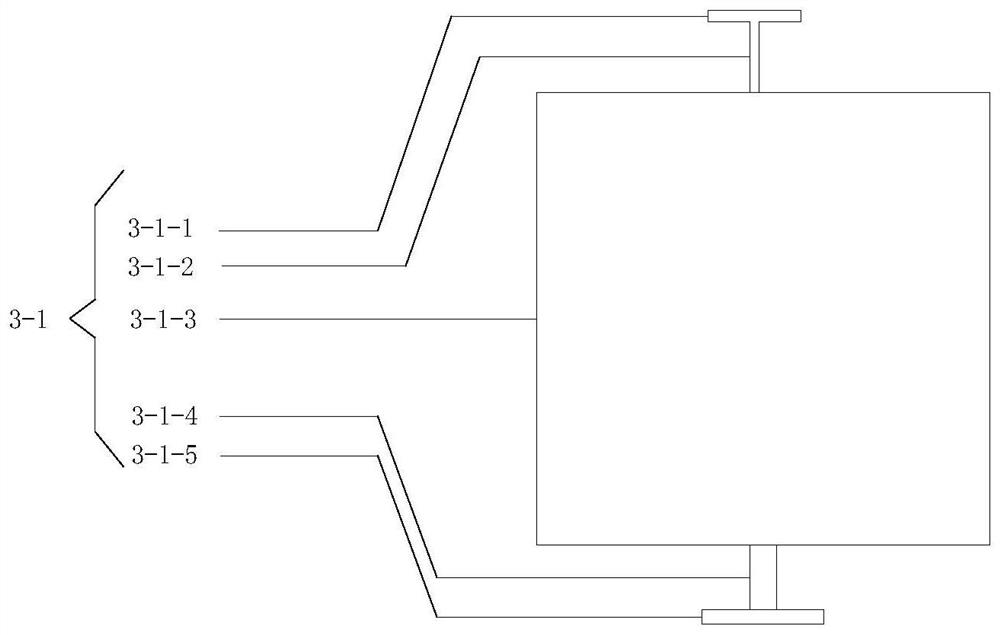

[0078] Wherein, the first rotating assembly 3-1 includes: an upper limiting plate 3-1-1, an upper connecting rod 3-1-2, a rotating plate...

Embodiment 2

[0096] Embodiment two, such as Figure 4-5 As shown, the advantage of embodiment two is to break this technical prejudice: the central axis of the lower gear 3-1-5 is on the same axis as the central axis of the rotating plate body 3-1-3;

[0097] The way of embodiment two is:

[0098] The rotating plate bodies of the first rotating assembly 3-1 and the second rotating assembly 3-2 are folded line plates, which include: the first folding plate body, the middle plate body, the second folding plate body, the first rotating assembly 3-1 The first flap body and the second flap body of the second rotating assembly 3-1 face the first side wall; the first flap body and the second flap body of the second rotating assembly 3-1 face the second side wall;

[0099]The upper connecting rod 3-1-2 is fixedly connected to the upper connecting plate, the lower connecting rod 3-1-4 is fixedly connected to the lower connecting plate, the top of the rotating plate body is fixedly connected to the...

Embodiment 3

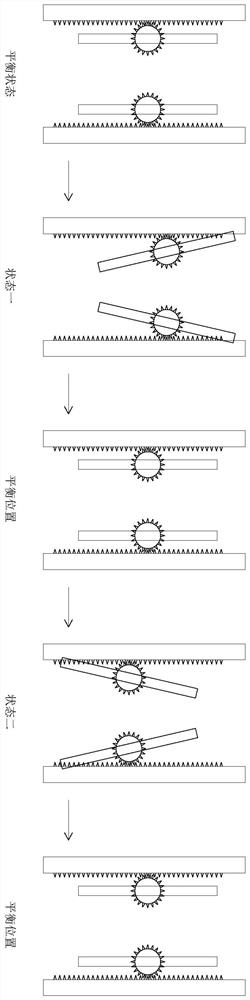

[0113] Embodiment 3, the solution of Embodiment 1 is to adjust the steering angle of the main body of the rotating plate through gears. That is, the steering angle-displacement is proportional.

[0114] The method of Embodiment 3 is to further meet the design requirements, that is, to meet: any S-β curve; S represents: the relative displacement between the upper box girder and the lower box girder, and β represents the displacement of the main body of the rotating plate under the displacement S turn angle.

[0115] For this requirement, make the following improvements:

[0116] The lower connecting rod 3-1-4 and the gear 3-1-5 are no longer necessary; the racks of the first base block and the second base block are also no longer necessary.

[0117] The lower end connecting rod 3-1-7 is arranged at the bottom front end and the rear end of the rotating plate body; Both sides of the connecting rod 3-1-2; and, the connecting line of the lower connecting rod 3-1-7 at the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com