A sand control well reservoir testing device

A testing device and oil reservoir technology, applied in measurement, wellbore/well components, construction, etc., can solve the problems of untrue data, difficult mining, unusable and other problems, and achieve the effect of small error, small size and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

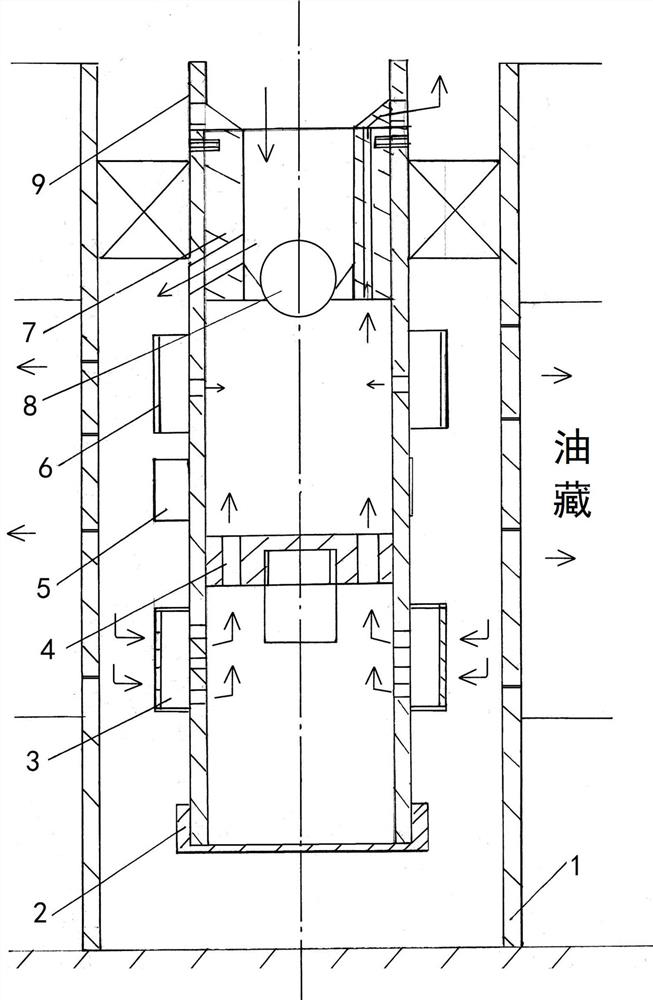

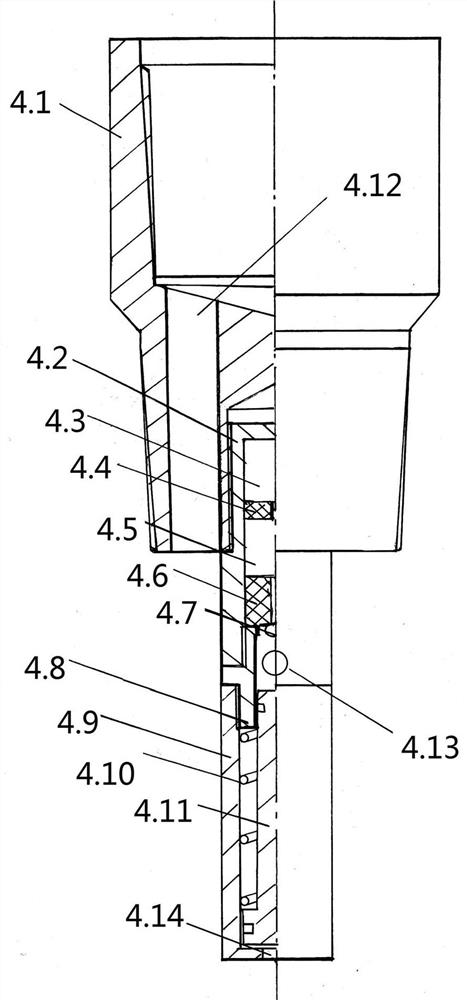

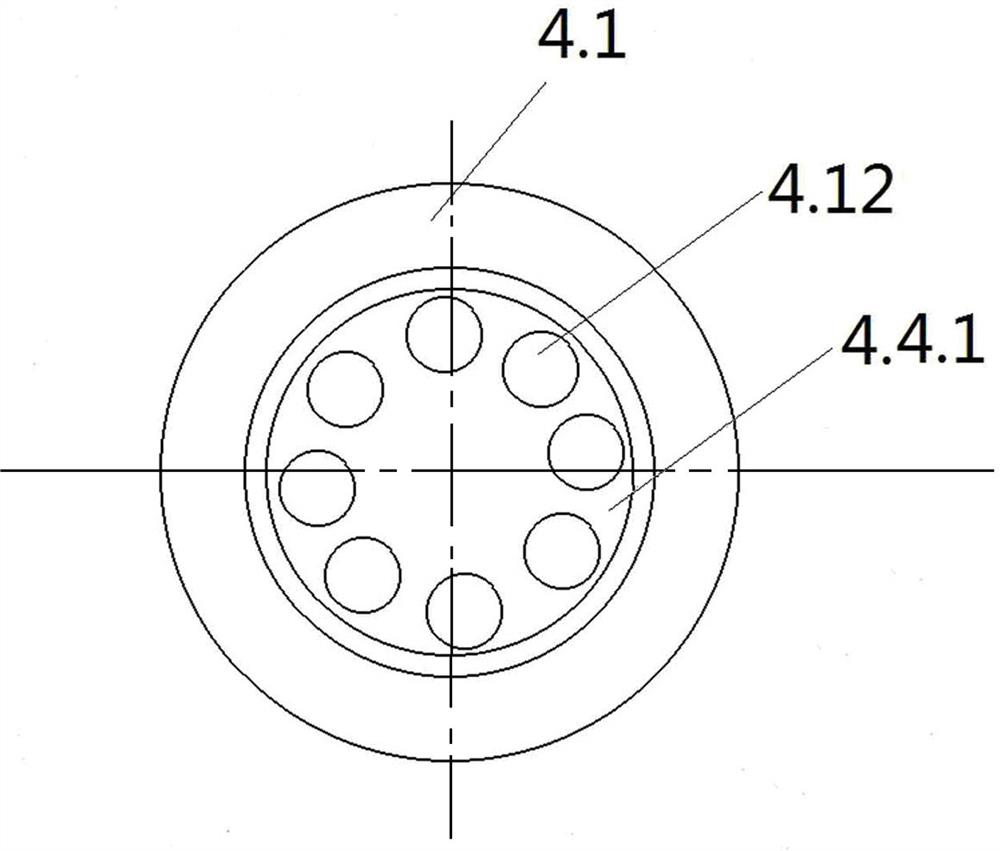

[0024] Embodiment 1, a sand control well reservoir testing device mentioned in the present invention, its technical solution is: including blind plugging 2, sand filter pipe 3, in-pipe tester 4, out-pipe tester 5, signal screen 6, filling Tool 7, pipe string 9, the filling tool 7 is installed in the inner cavity of the lower side of the pipe string 9, the signal screen 6 is arranged on the lower side of the filling tool 7, and the external tester 5 is arranged below the signal screen 6 , a filter sand tube 3 is provided below the external tester 5, and a blind plug 2 is provided at the bottom of the filter sand tube 3; an internal tester is installed between the bottom of the external tester 5 and the filter sand tube 3 4;

[0025] refer to Figure 4 , the tester outside the tube 5 includes a test carrier 5.1, a test sand retaining cover 5.2, a shock absorbing spring 5.4, an electronic tester 5.5, and a tester operation protection sand filter screen 5.6, and the test carrier ...

Embodiment 2

[0041] Embodiment 2, a sand control well reservoir testing device mentioned in the present invention, its technical solution is: including blind plug 2, sand filter pipe 3, in-pipe tester 4, out-pipe tester 5, signal screen 6, filling Tool 7, pipe string 9, the filling tool 7 is installed in the inner cavity of the lower side of the pipe string 9, the signal screen 6 is arranged on the lower side of the filling tool 7, and the external tester 5 is arranged below the signal screen 6 , a filter sand tube 3 is provided below the external tester 5, and a blind plug 2 is provided at the bottom of the filter sand tube 3; an internal tester is installed between the bottom of the external tester 5 and the filter sand tube 3 4;

[0042] refer to Figure 4 with 5 , the tester outside the tube 5 includes a test carrier 5.1, a test sand retaining cover 5.2, a shock absorbing spring 5.4, an electronic tester 5.5, and a tester operation protection sand filter screen 5.6, and the test carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com