A Synchronous Drainage Method for Repetitive Hydraulic Fracturing Displacing Gas in Soft Coal Seam

A technology of hydraulic fracturing and gas drainage, which is applied in the direction of gas discharge, mining equipment, mining fluids, etc., can solve the problems of short duration of gas drainage in coal seams, reduce the risk of outburst, reduce the quantity, and improve gas drainage. The effect of mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

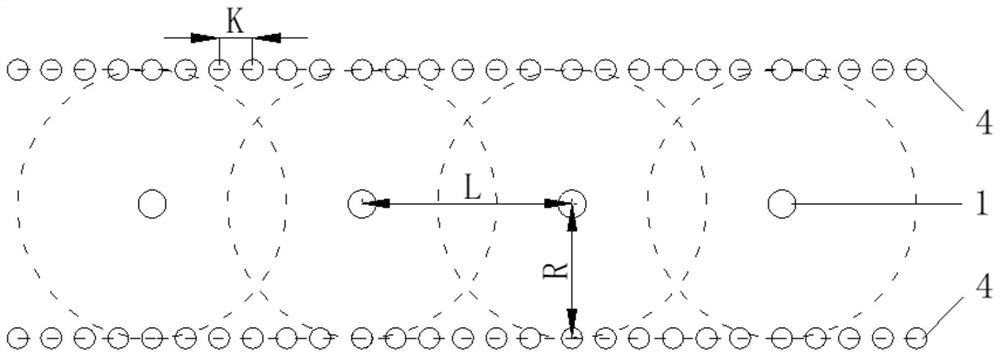

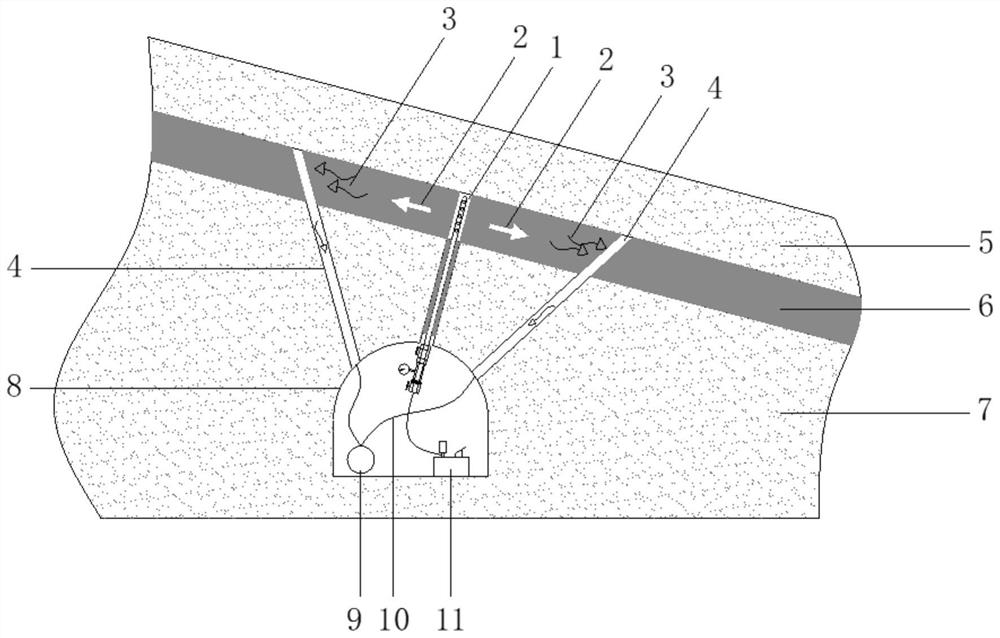

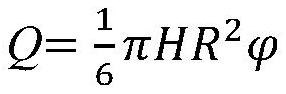

[0061] A method for synchronous drainage of gas by repeated hydraulic fracturing in soft coal seams with a thickness of 4m, see Figure 1 ~ Figure 2 , along the strike direction of the coal seam 6, the bed-crossing hydraulic fracturing borehole 1 is arranged, and the bed-crossing hydraulic fracturing borehole 1 is arranged on both sides of the bed-crossing gas drainage borehole 4, and the coal seam top plate 5 and the coal seam bottom plate 7 respectively The upper and lower sides of the upper and lower sides of the coal seam 6 are provided with a main gas drainage pipeline 9 and a hydraulic fracturing pump set 11 in the floor rock roadway 8 below the coal seam 6. The main drainage pipeline 9 is connected, and the hydraulic fracturing drilling 1 through the layer is connected with the hydraulic fracturing pump set 11; the high-pressure water in the hydraulic fracturing drilling 1 through the layer figure 2 The high-pressure water in the flow direction 2 penetrates to the surr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com