Electric starting fusing type quick release valve

A fuse type, electric start technology, applied in the field of emergency life-saving, can solve the problems of high cost, high processing difficulty and high production safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

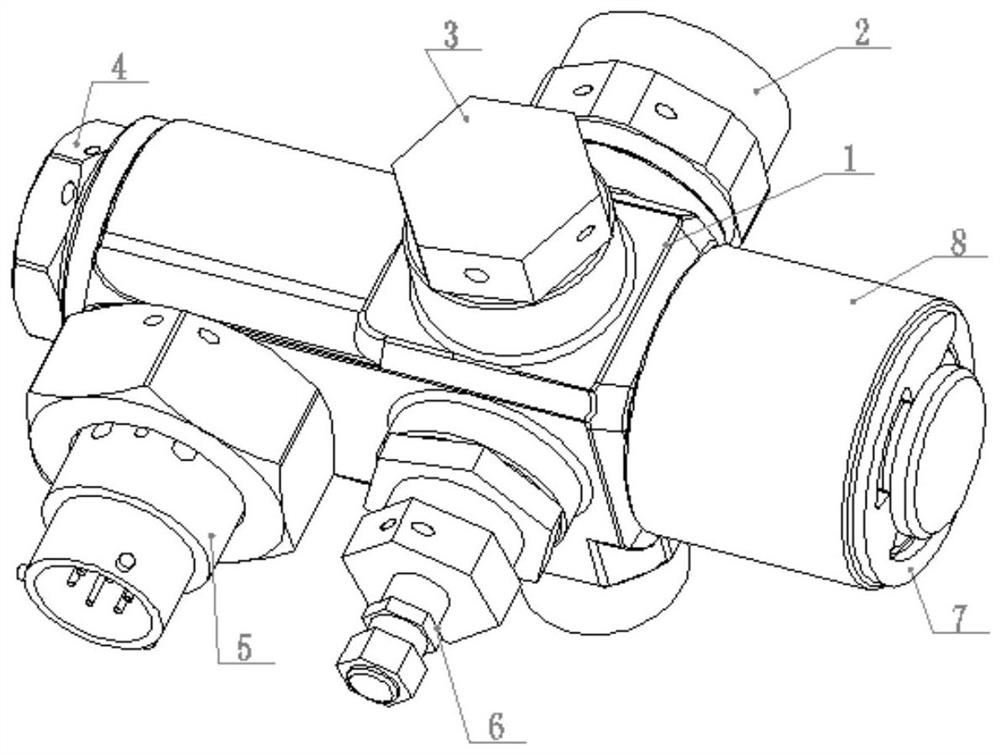

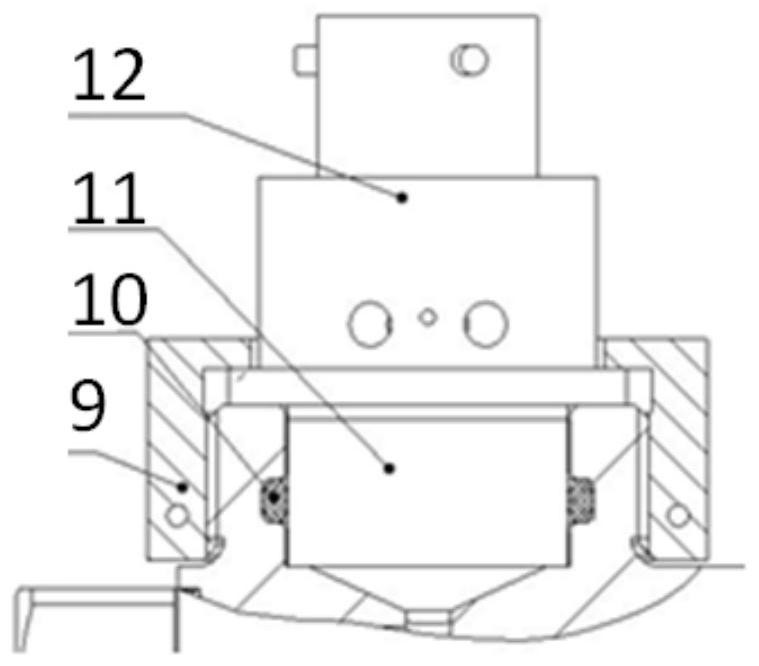

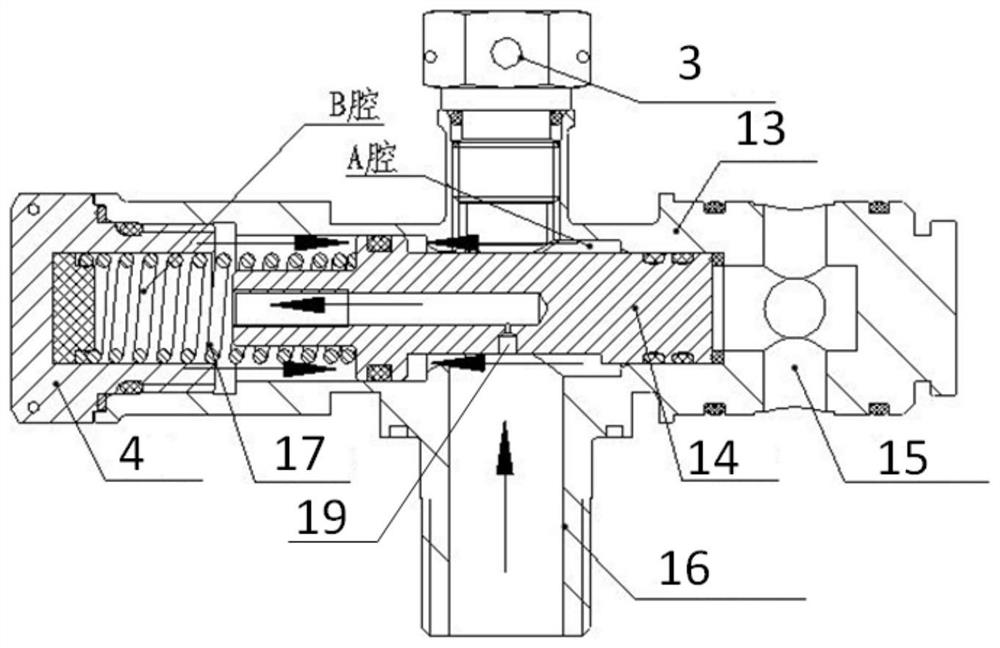

[0027] An electric start fuse type quick release valve, comprising a valve body main part 1, a pressure gauge 2, a safety valve 3, a plug cap 4, a bottle opening device 5, an inflation valve 6, a retaining spring 7, a protective sleeve 8, and a compression nut 9. Sealing ring 10, fusible plug 11, electrical connector 12, housing 13, valve core 14, output port 15, gas cylinder port 16, spring 17, O-ring 18, orifice 19, etc.

[0028] The spring 17 is assembled on the left end step shaft of the valve core 14, and then the corresponding O-ring is assembled in the sealing ring groove of the valve core, and the valve core 14 is assembled inside the upper casing 13 of the main part of the valve body 1 In the channel, the plug cap 4 is installed on the left side of the valve core 14 and the side of the spring 17. The plug cap 4 and the housing 13 are connected by internal threads, and the spring 17 is restrained. A certain pre-tightening force is applied to the spring 17 through the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com