Biomass fuel combustion furnace facilitating sufficient combustion

A biomass fuel, full combustion technology, applied in the direction of combustion air/fuel supply, combustion method, combustion equipment, etc., can solve the problems of insufficient air supply, low combustion efficiency, high manufacturing cost and difficulty, and achieves reduced production difficulty, The effect of improving combustion efficiency and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

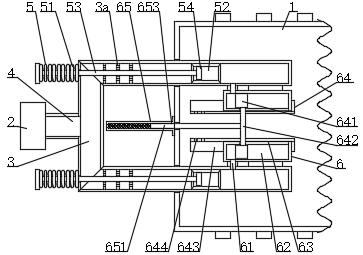

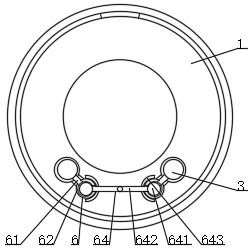

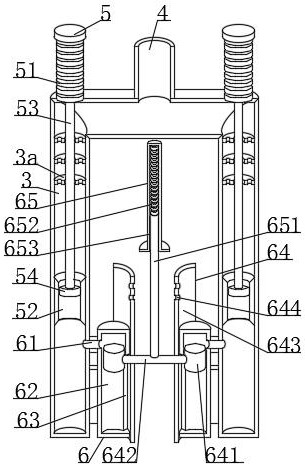

[0031] refer to Figure 1-5 , a biomass fuel combustion furnace that is convenient for full combustion, including a combustion furnace body 1 and an air pump 2, the feed end of the combustion furnace body 1 is connected with a pressure accumulation tube 3, and the left end of the pressure accumulation tube 3 is fixedly connected with a butt joint 4 , the left end of the butt joint pipe 4 is fixedly connected to the output end of the air pump 2, the left end of the pressure accumulation pipe 3 is fixedly connected with a booster mechanism 5, and the right end of the pressure accumulation pipe 3 is fixedly connected with a guide mechanism 6.

[0032] In this example, if figure 1 , figure 2 with image 3 As shown, the inner side of the pressure accumulator tube 3 is fixedly connected with a flame extinguishing plate 3a. By adding the flame extinguishing plate 3a inside the pressure accumulator tube 3, the flame inside the combustion furnace body 1 is prevented from passing alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com