A gas bearing centrifugal compressor

A centrifugal compressor and gas bearing technology, applied in the field of compressors, can solve the problems of fluctuating exhaust pressure, low gas density, poor economy, etc., and achieve the effects of stable control angle, stable outlet water temperature, and stable evaporation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

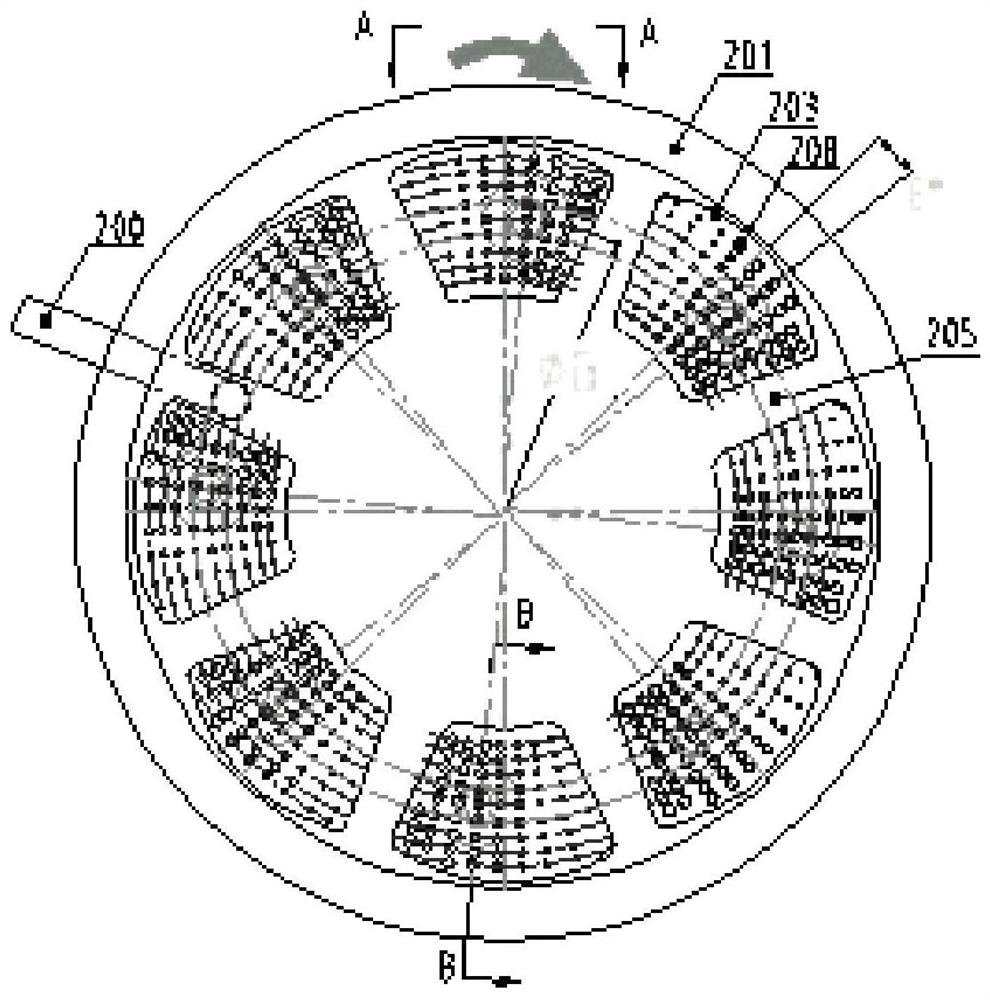

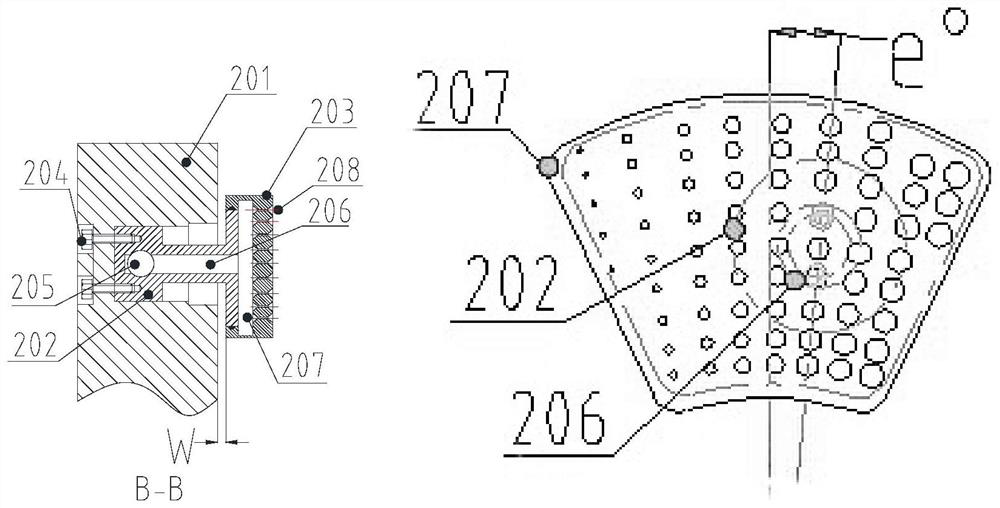

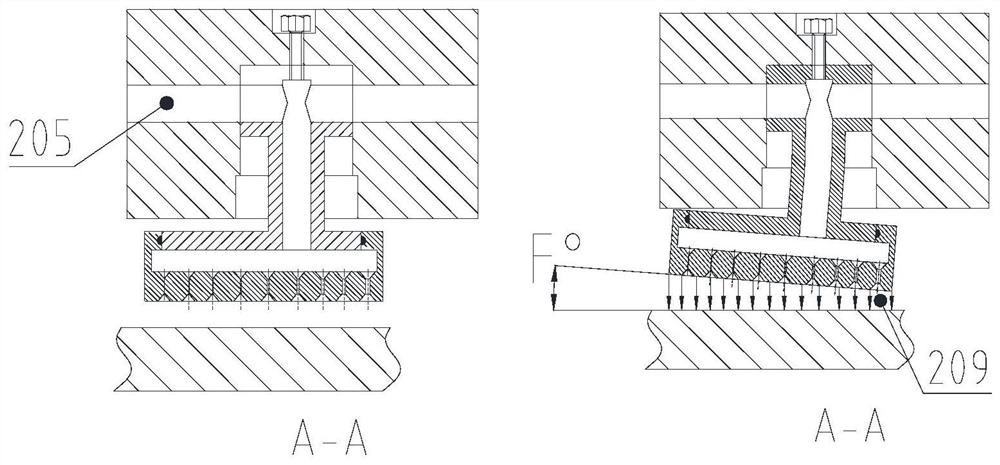

[0048] A gas bearing centrifugal compressor provided in this embodiment, figure 1 The thrust bearing comprises a housing 201 and a plurality of mounted bottom support cylinders or flexible rod cylinders 202 and 203 . The number of thrust plates is designed according to the thrust force. The annular design is more than 4 thrust plates. The thrust sector can be fan-shaped or circular. It is designed according to the thrust force. The larger the area of the thrust surface, the greater the thrust force. bigger. 205 is an annular gas supply channel, and 200 is a total gas supply port. The total intake channel 200 draws a part of high-pressure and high-speed gas from the total gas supply channel 107 of the gas bearing, and distributes the high-pressure and high-speed gas evenly to the internal air flow channels 206 of each thrust plate 202 through the annularly arranged 205 channels. For the convenience of manufacture, the annular gas supply channel can be designed as an externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com