Central flue air volume control method and system

An air volume control system and air volume control technology, which are applied in heating methods, oil fume removal, lighting and heating equipment, etc., can solve problems such as inability to distribute air volume on floors, and achieve the effect of eliminating smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

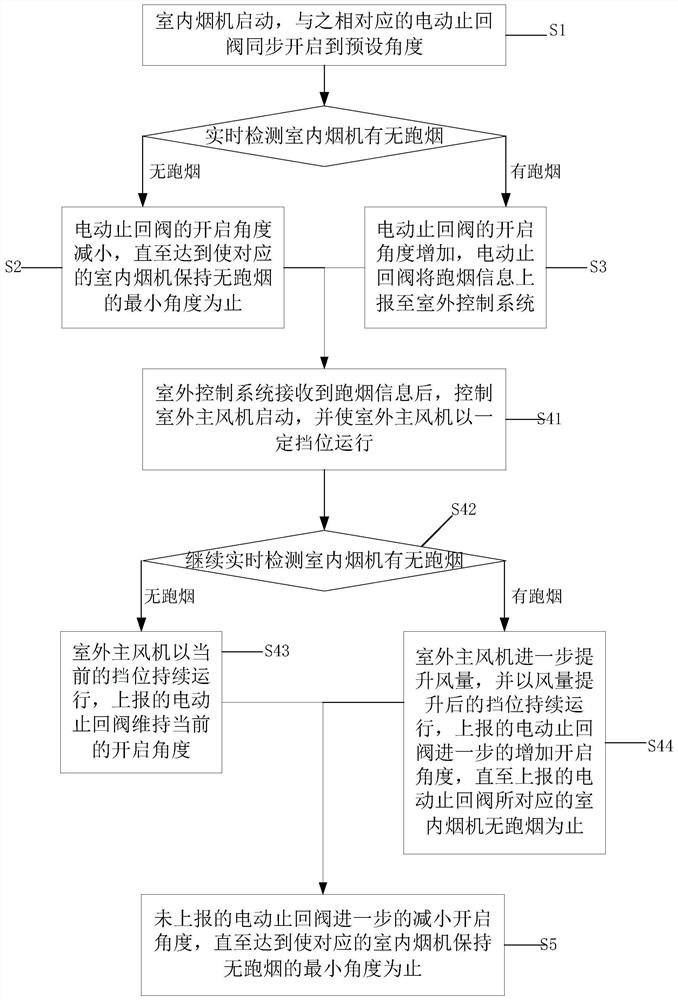

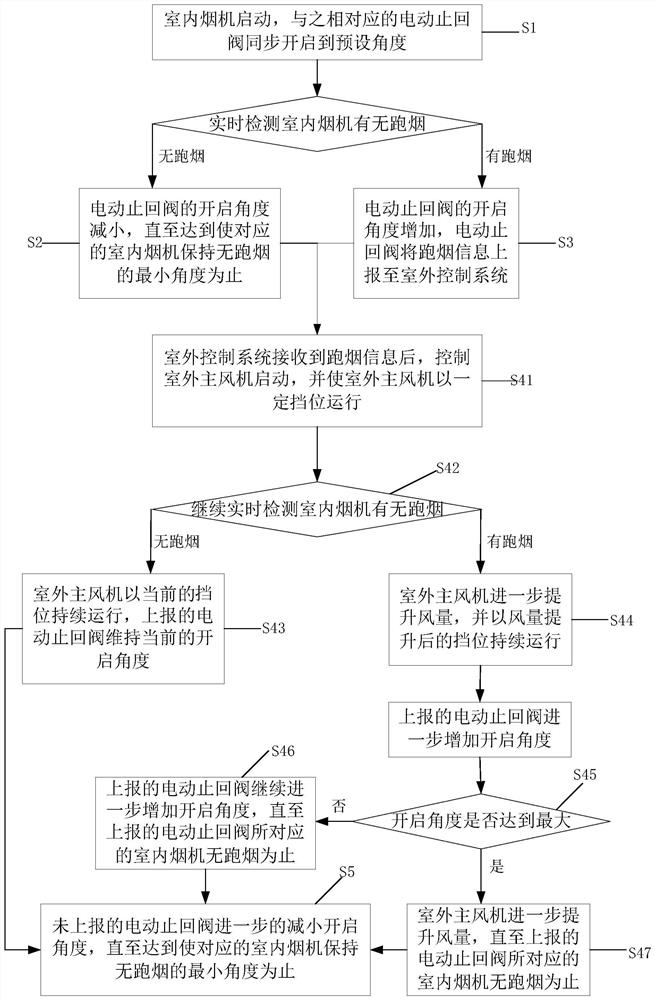

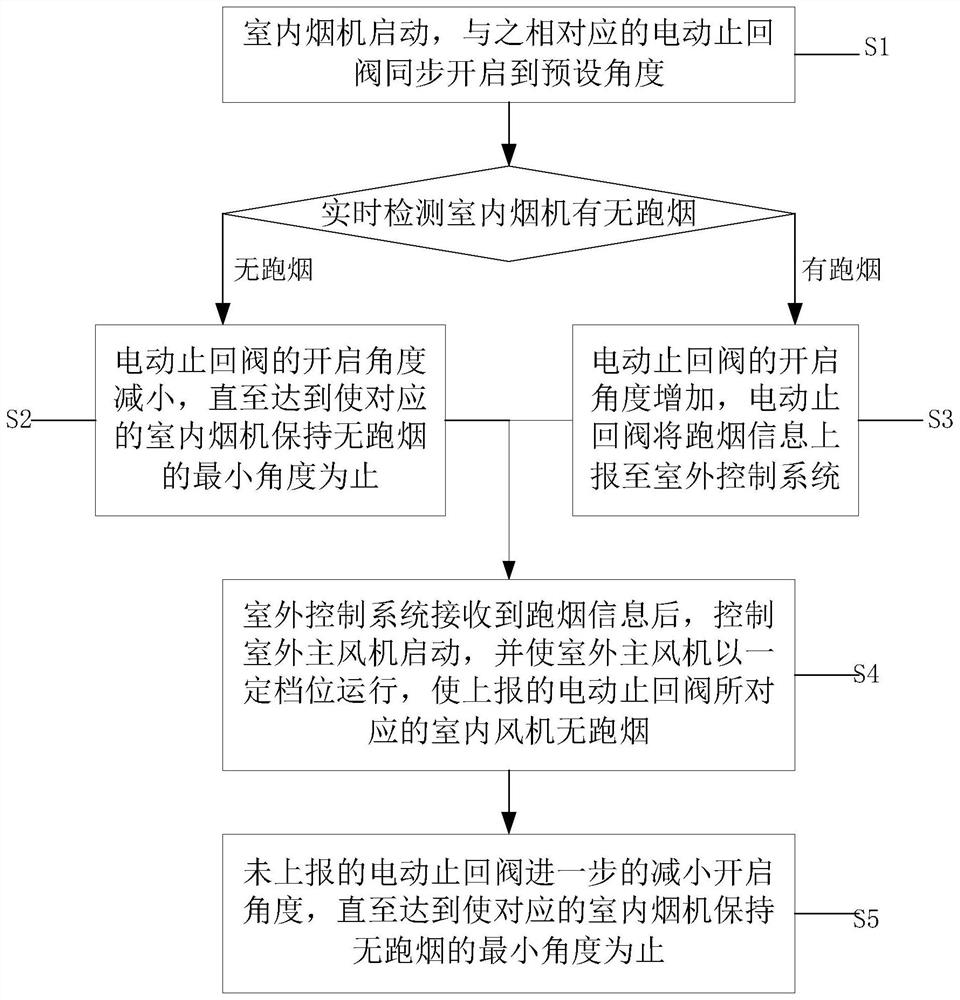

[0049] Such as figure 1 As shown, the present embodiment provides a central flue air volume control method, the method includes the following steps:

[0050] S1. Start the indoor hood, and the corresponding electric check valve is synchronously opened to the preset angle to detect in real time whether there is any smoke from the indoor hood; if there is no smoke, go to S2; if there is smoke, go to S3 ;

[0051] S2. The opening angle of the electric check valve is reduced until it reaches the minimum angle at which the corresponding indoor range hood remains free of smoke;

[0052] S3. The opening angle of the electric check valve is increased, and the electric check valve will report the smoke information to the outdoor control system;

[0053] S4. After receiving the smoke information, the outdoor control system controls the outdoor main fan to start, and makes the outdoor main fan run at a certain gear, so that the indoor hood corresponding to the reported electric check v...

Embodiment 2

[0074] Such as Figure 4 and Figure 5 As shown, this embodiment provides a central flue air volume control system, including an indoor smoke machine 1 installed on each floor, an outdoor control system, a smoke detection component 3 and an electric check valve 5;

[0075] Each indoor smoke machine 1 communicates with the public flue 4 through its own smoke pipe 11, and an electric check valve 5 is installed on each smoke pipe 11; the smoke detector assembly 3 is connected with each indoor smoke machine 1 for detection Whether the indoor smoke machine 1 runs out of smoke; the outdoor control system includes the outdoor main fan 2 installed at the air outlet of the public flue 4, and the outdoor control system is connected with each electric check valve 5 for communication according to the received electric check valve. 5 to control the opening, closing, and gear adjustment of the outdoor main fan 2 by sending out smoke information.

[0076] Because the smoke detector compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com