Method and device for capturing complex flue gas on smelting pot surface

A technology of flue gas capture and smelting pots, which is applied in the direction of stirring devices, furnaces, lighting and heating equipment, etc., to solve the problem of running and smoking, to ensure sealing, and to protect the service life of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described below in conjunction with the accompanying drawings and embodiments. It should be noted that specific embodiments of the present invention are only intended to be able to more clearly describe the technical solution, and can not be used as a limitation of the scope of protection of the present invention.

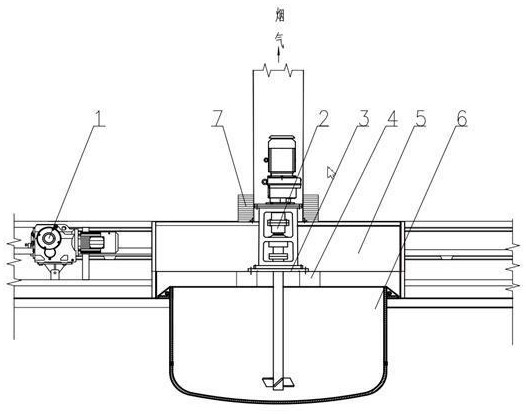

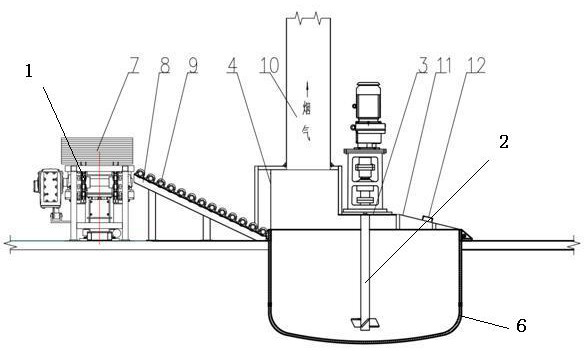

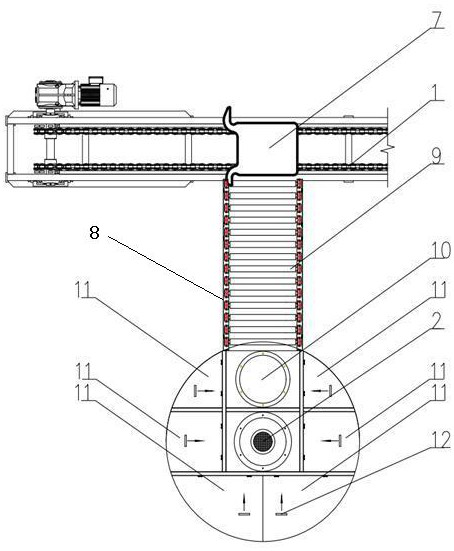

[0035] See Figure 1-4 , a smelting pot surface complex flue gas capture method and device, the device is made of steel plate and other materials, the setting is covered on the edge of the smelting pot, mainly including the feeding device and the two parts of the 5 body of the hood.

[0036] The feed device comprises a chain conveyor 1, an infeed drum rack 8 and a roller 9, the device is an existing device, not a detailed table herein.

[0037] The working process of the present invention is:

[0038]First, through the chain conveyor 1 to transmit the residual pole or precipitate lead 7 to the hood 5 corresponding to the rear end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com