Liquid injection device for electronic cigarette production line

A liquid injection device and electronic cigarette technology, applied in the direction of tobacco, etc., can solve the problems that affect the injection quality, cannot guarantee the uniform injection volume, and cannot control the injection volume, so as to ensure the injection quality, avoid splashing, and uniform injection volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

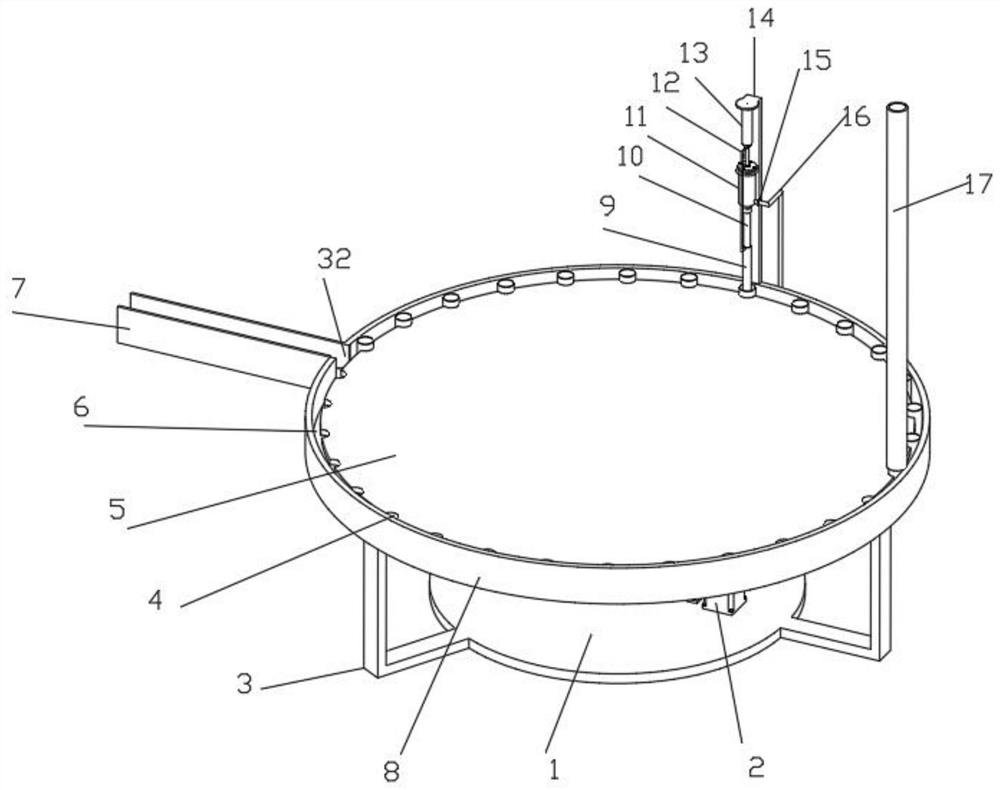

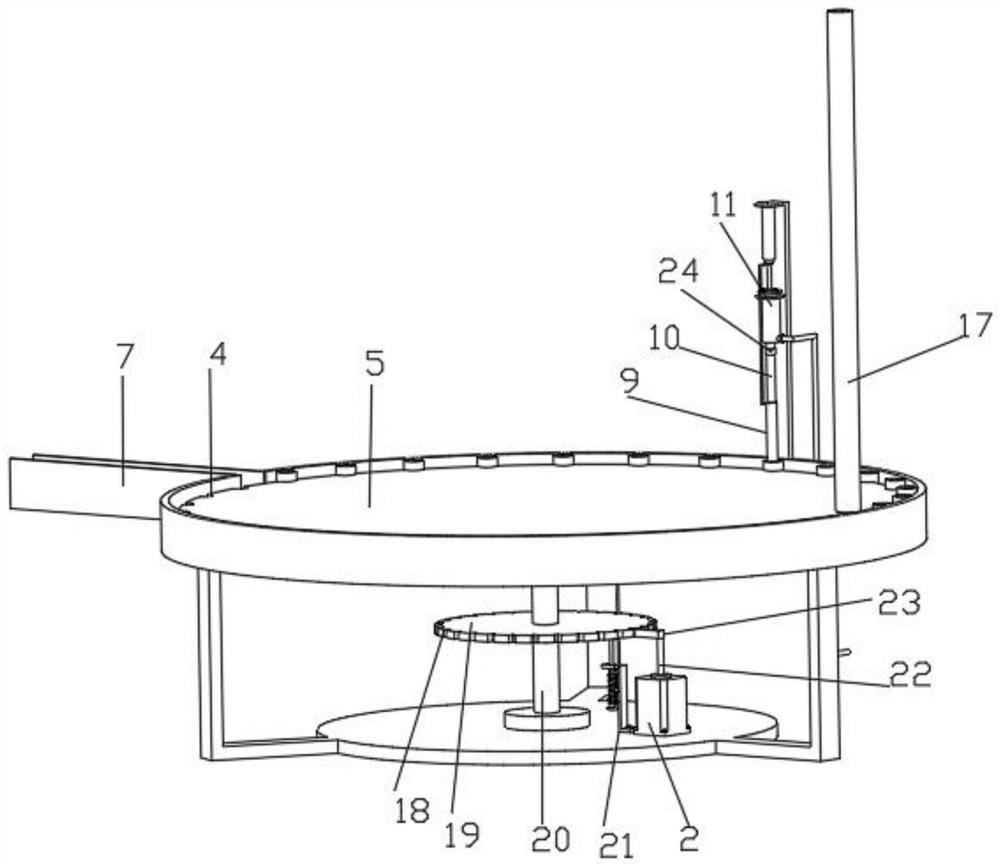

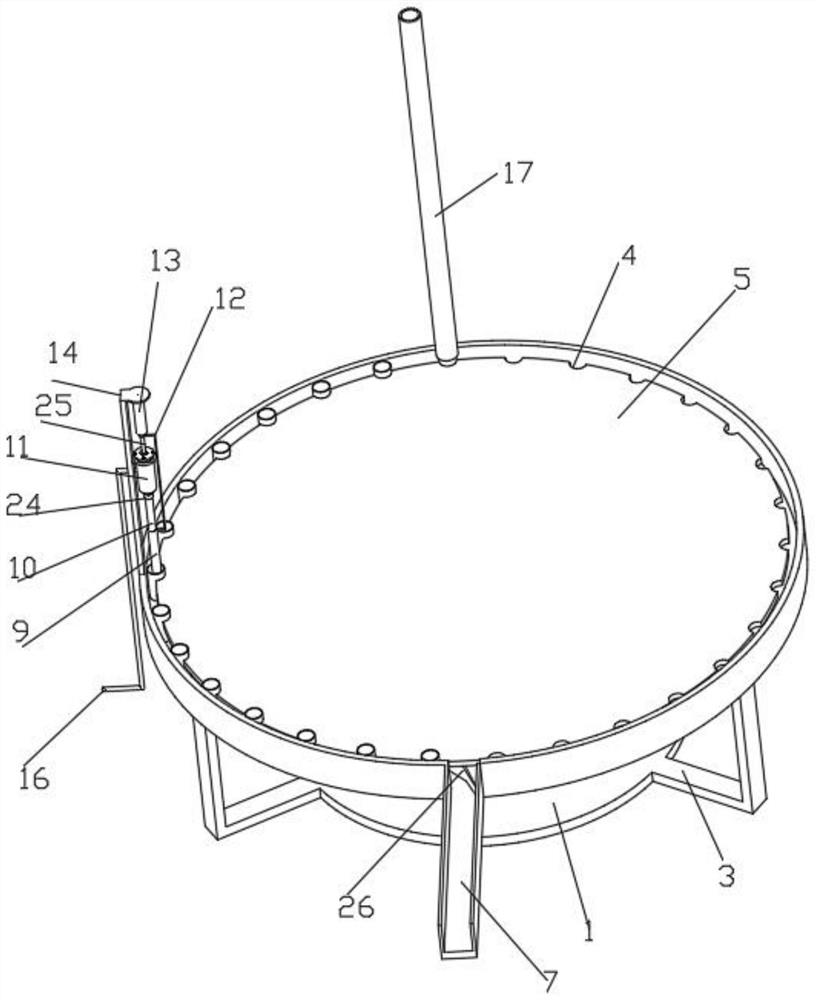

[0030] Such as figure 1 , 2 A liquid injection device for an electronic cigarette production line shown in 3, 4, and 6 includes a bottom plate 1, an intermittent pushing structure is connected to the top of the bottom plate 1, and the gap pushing structure includes a driving motor 2, an L-shaped plate 3, a semicircular groove 4, The first rotating circular plate 5, the outer ring 8, the driving groove 18, the second rotating circular plate 19, the rotating rod 20, the rotating shaft 22 and the driving block 23, the top middle end of the bottom plate 1 is rotatably connected with the rotating rod through a fixedly connected bearing 20. The output end of the driving motor 2 is fixedly connected to the rotating shaft 22, the top of the rotating shaft 22 is fixedly connected to the driving block 23, the middle end of the rotating rod 20 is guessed to be fixedly connected to the second rotating circular plate 19, and the outer surface of the second rotating circular plate 19 The e...

Embodiment 2

[0033] Embodiment 2 is a further improvement to Embodiment 1.

[0034] Such as figure 1 , 2 , The braking structure shown in 4 and 5 comprises Z-shaped plate 21, spring 27, disc 28, rubber plate 29 and movable bar 30, and the bottom of the top transverse part of Z-shaped plate 21 is fixedly connected with spring 27, and the bottom of spring 27 Fixedly connected with a circular plate 28, the top of the circular plate 28 is fixedly connected with a movable rod 30, the top of the movable rod 30 runs through the spring 27 and the Z-shaped plate 21 and is fixedly connected with a rubber plate 29, the top of the rubber plate 29 is connected with the second rotating circular plate The bottom of 19 fits and slides, and the bottom transverse part of the Z-shaped plate 21 is fixed on the top of the bottom plate 1 by bolts. The spring 27 of the braking structure drives the circular plate 28 to move upward, and the circular plate 28 drives the movable rod 30 to move, and the movable rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com