Preparation device of water-soluble organic carbon fertilizer

A technology for preparing a device and organic carbon is applied in the field of stirring tanks, which can solve the problems of ratio error, bonding of mixed raw materials, and volume reduction, and achieve the effect of avoiding force damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

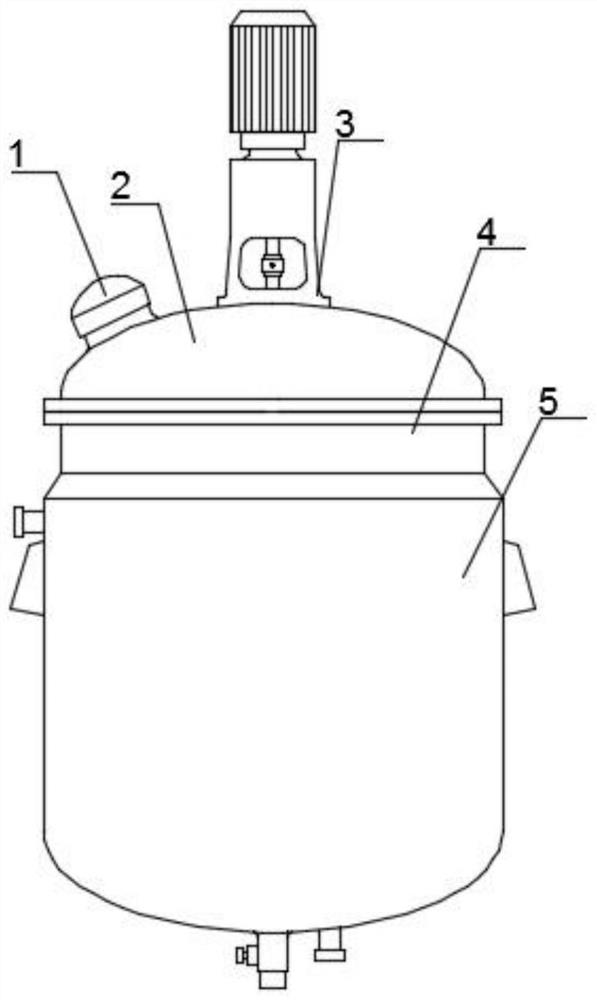

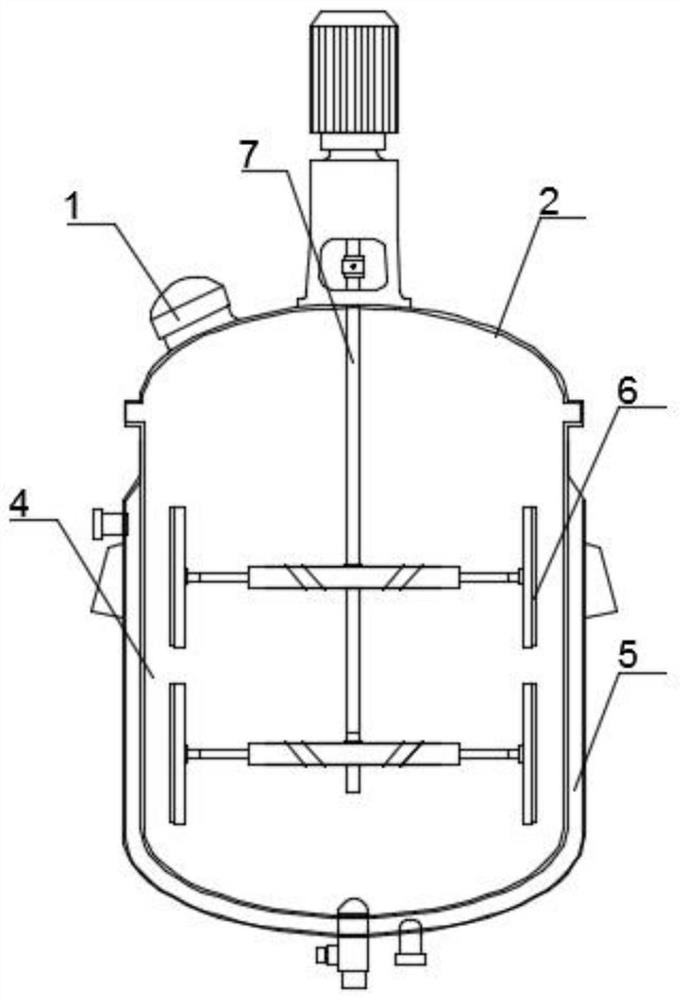

[0025] Such as Figure 1-3 Shown, a kind of preparation device of water-soluble organic carbon fertilizer comprises kettle body 4 and kettle cover 2, and the top of kettle body 4 is equipped with kettle cover 2, and the center of kettle cover 2 top is set up with driving assembly 3; A drive rod 7 is provided, and the drive assembly 3 is transmission-connected to the drive rod 7. The periphery of the drive rod 7 is connected with an adaptive wall scraper assembly 6 at the upper and lower positions, and the self-adaptive wall scraper assembly 6 is connected to the drive rod in a horizontally symmetrical manner. 7, the self-adaptive wall scraper assembly 6 includes a stirring tube 61, a telescopic rod 62 and an adaptive scraper 65, the stirring tube 61 is symmetrically connected to the driving rod 7, the inside of the stirring tube 61 is a circular cavity, and the inside of the stirring tube 61 A telescopic rod 62 is inserted, and one end of the telescopic rod 62 is connected to ...

Embodiment 2

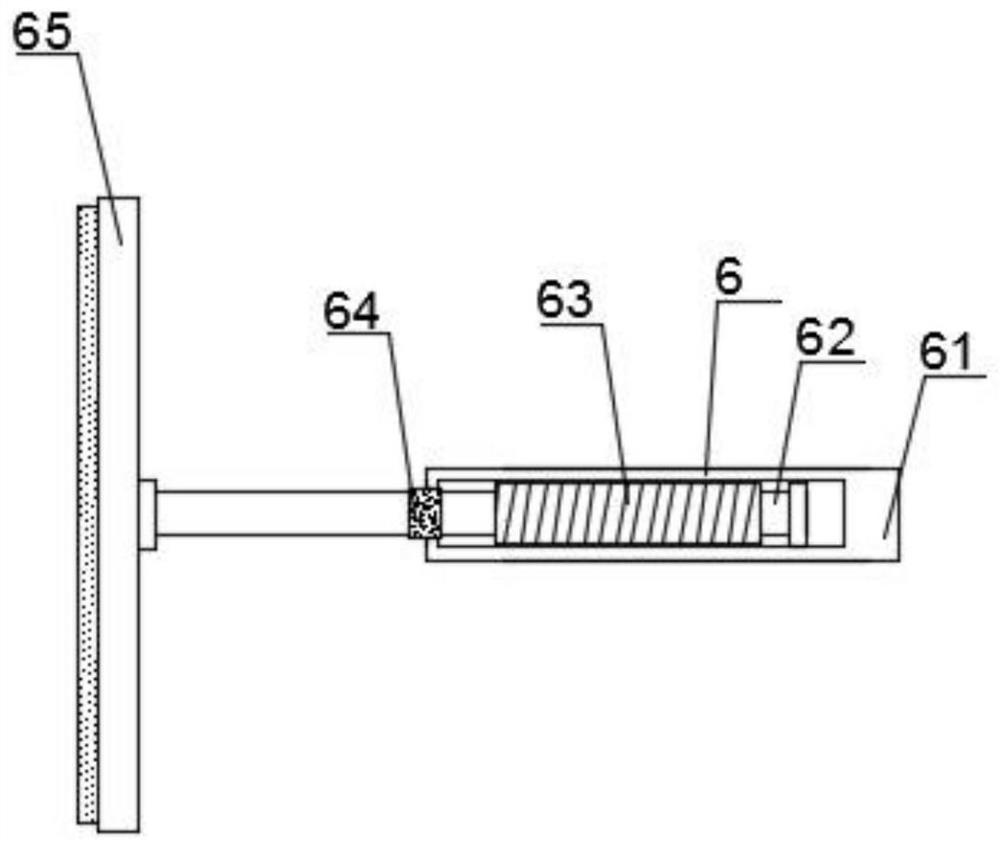

[0028] Such as Figure 2-3 As shown, a water-soluble organic carbon fertilizer preparation device, the port of the telescopic rod 62 is embedded with a sealing ring 64, and the telescopic rod 62 is inserted from the sealing ring 64; A spring 63 is provided, and the telescopic rod 62 is interspersed in the spring 63. The spring 63 moves in the stirring tube 61. The diameter of the limit block at the telescopic rod 62 is larger than the port diameter of the spring 63. When the spring 63 is compressed to the maximum stroke, the self-adaptive scraper 65 contacts The inner wall of the self-adaptive scraper assembly 6 .

[0029] In this embodiment, based on the fact that the spring 63 is limited in the stirring tube 61, the spring 63 is compressed and deformed under the centrifugal force, and the telescopic rod 62 is contracted when the centrifugal force is smaller than the recovery force of the spring 63, thereby avoiding The self-adaptive scraper 65 cannot return to the initial p...

Embodiment 3

[0031] Such as Figure 4 As shown, a preparation device for water-soluble organic carbon fertilizer, the self-adaptive scraper 65 includes a knife holder 651, a movable slot 652 and a movable rod 654, the knife holder 651 is vertically fixed on the telescopic rod 62, and the knife holder 651 is provided with a Gourd-shaped movable slot 652, a gourd-shaped movable rod 654 is embedded in the movable groove 652, and one end of the movable rod 654 is fixed with a scraper 655 near the inner wall of the kettle body 4; the opposite part of the scraper 655 is located on the surface of the movable rod 654 A return spring 653 is provided, and the return spring 653 is symmetrically connected to both sides of the movable rod 654 in an oblique layout, and the return spring 653 is sandwiched between the knife holder 651 and the movable rod 654 .

[0032] In this embodiment, based on the fact that the inner wall of the kettle body 4 is not a real ring-shaped inner wall, by setting the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com