Cylinder welding fixture

A welding fixture and cylinder technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low productivity and uneven welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

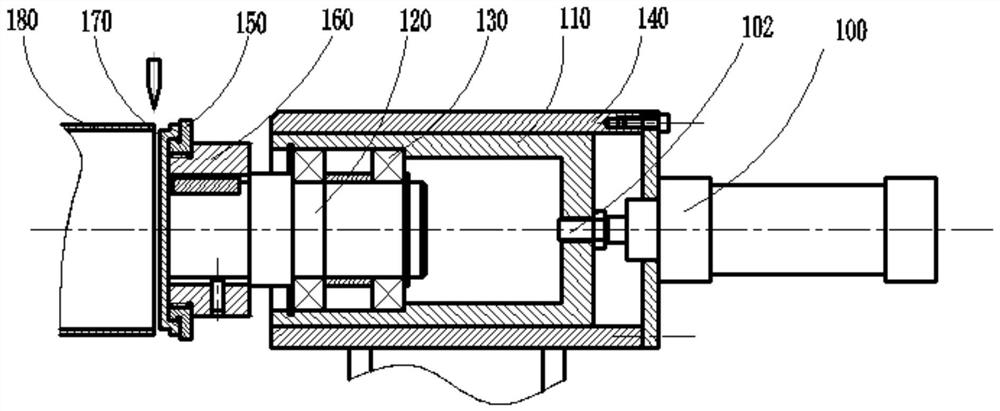

[0014] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 As shown, this is a preferred embodiment of the present invention, a cylindrical welding fixture, including a pneumatic clamping device, the pneumatic clamping device includes a cylinder 100, an inner sleeve 110 and a rotating shaft 120, and the cylinder 100 passes through the inner sleeve The sleeve 110 is connected to the rotating shaft 120, and the cylinder rod 102 of the cylinder 100 is connected to the inner sleeve 110 through threads. During the process of adding a back cover 170 to the cylinder 180, the cylinder 100 drives the inner sleeve 110 to place the cylinder on the rotating shaft 120. The bottom cover 170 is pressed into the cylinder 180, and the rotating shaft 120 can rotate freely. During welding, the three-jaw chuck drives the cylinder 180 to rotate, and the bottom cover 170 rotates synchronously with the cylinder 180 to complete the circular seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com