Wall surface cleaning machine for building decoration and operation method thereof

A cleaning machine and construction technology, applied in the field of building decoration and decoration, can solve the problems that the convex and concave walls cannot be cleaned at the same time, the labor intensity of operators, and the inability to clean dust, etc., so as to improve the decoration quality, improve the dust removal effect, and enhance the environmental protection performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

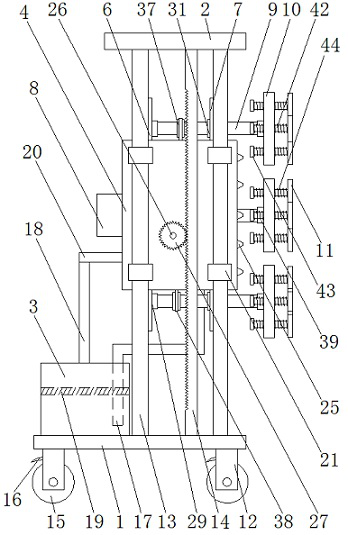

Embodiment 1

[0038] as attached Figure 1-10 As shown, a wall cleaning machine for building decoration, including a bottom plate 1, a top plate 2, a dust collection chamber 3, a moving plate 4, a motor one 5, a bearing plate one 6, a bearing plate two 7, a motor two 8, and a driven shaft 9. The rotating plate 10 and the grinding disc 11 are characterized in that: the bottom plate 1 is set on the bracket 12, and a column 13 and a tooth column 14 are vertically arranged on the bottom plate 1, and the top plate 2 is set on the column 13 1. On the gear tooth column 14, between the base plate 1 and the support 12, the column 13, the gear tooth column 14 and between the top plate 2 and the column 13, the gear tooth column 14 are connected by welding, which improves the connection strength of the wall cleaning machine, and then To improve the structural strength of the wall cleaning machine, the dust collection chamber 3 is arranged on the bottom plate 1, and the dust collection chamber 3 is prov...

Embodiment 2

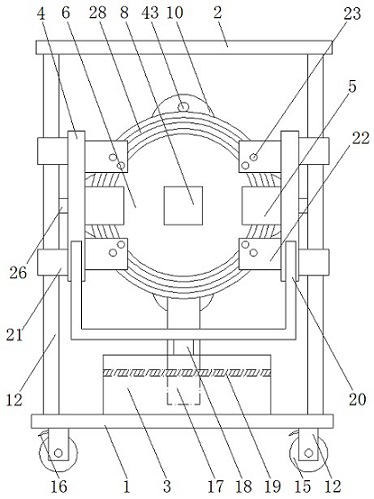

[0054] as attached Figure 11-12 As shown, a wall cleaning machine for building decoration, including a bottom plate 1, a top plate 2, a dust collection chamber 3, a moving plate 4, a motor one 5, a bearing plate one 6, a bearing plate two 7, a motor two 8, and a driven shaft 9. The rotating plate 10 and the grinding disc 11 are characterized in that: the bottom plate 1 is set on the bracket 12, and a column 13 and a tooth column 14 are vertically arranged on the bottom plate 1, and the top plate 2 is set on the column 13 1. On the gear tooth column 14, between the base plate 1 and the support 12, the column 13, the gear tooth column 14 and between the top plate 2 and the column 13, the gear tooth column 14 are connected by welding, which improves the connection strength of the wall cleaning machine, and then To improve the structural strength of the wall cleaning machine, the dust collection chamber 3 is arranged on the bottom plate 1, and the dust collection chamber 3 is pro...

Embodiment 3

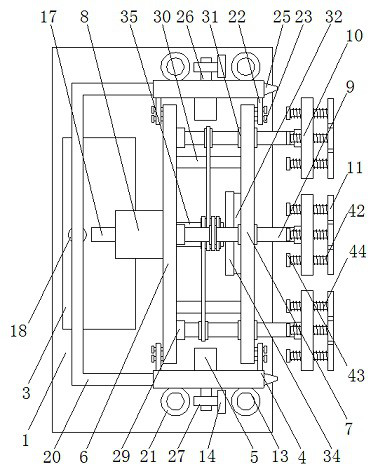

[0071] as attached Figure 13-14 As shown, a wall cleaning machine for building decoration, including a bottom plate 1, a top plate 2, a dust collection chamber 3, a moving plate 4, a motor one 5, a bearing plate one 6, a bearing plate two 7, a motor two 8, and a driven shaft 9. The rotating plate 10 and the grinding disc 11 are characterized in that: the bottom plate 1 is set on the bracket 12, and a column 13 is vertically arranged on the bottom plate 1, and the top plate 2 is set on the column 13, and on the top plate 2. A connecting rope 48 is provided on the back, and the bottom plate 1, the bracket 12, the column 13, and the top plate 2 and the column 13 are connected by welding, which improves the connection strength of the wall cleaning machine, and then improves the structure of the wall cleaning machine. Intensity, the dust collection chamber 3 is set on the bottom plate 1, and the dust collection chamber 3 is provided with an air inlet pipe 17 and an air delivery pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com