Pantograph wear-resistant metal bow angle with isolation buffer layer

A wear-resistant metal and buffer layer technology, applied in the field of pantographs, can solve problems affecting the normal function of pantographs, protection of metal bow angle tube substrates, high hardness of wear-resistant coatings, etc., to ensure safe and efficient operation, improve Use reliability, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

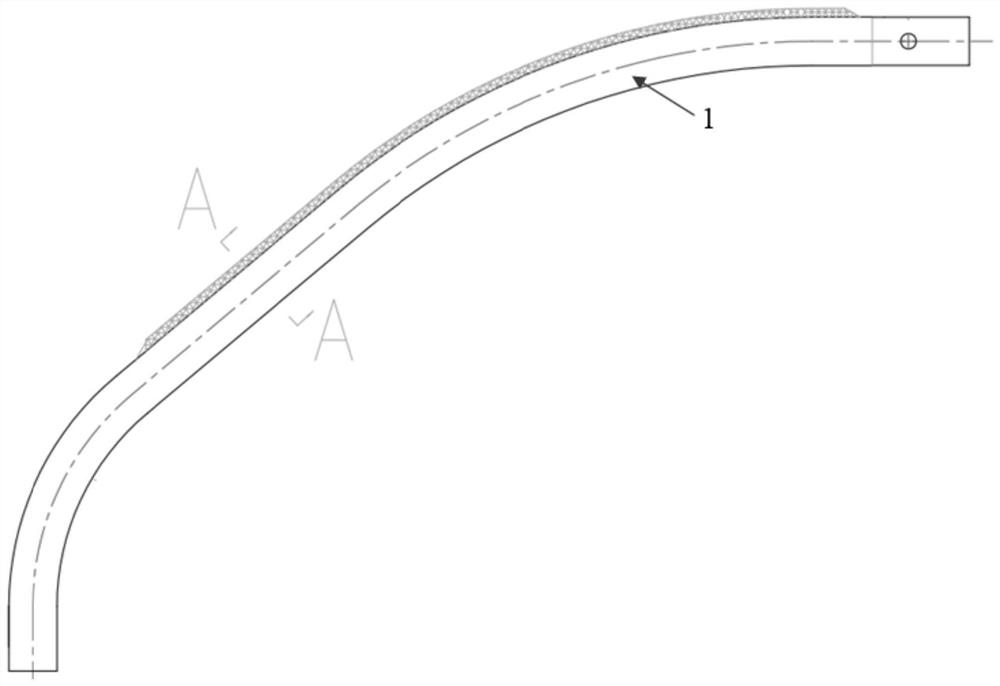

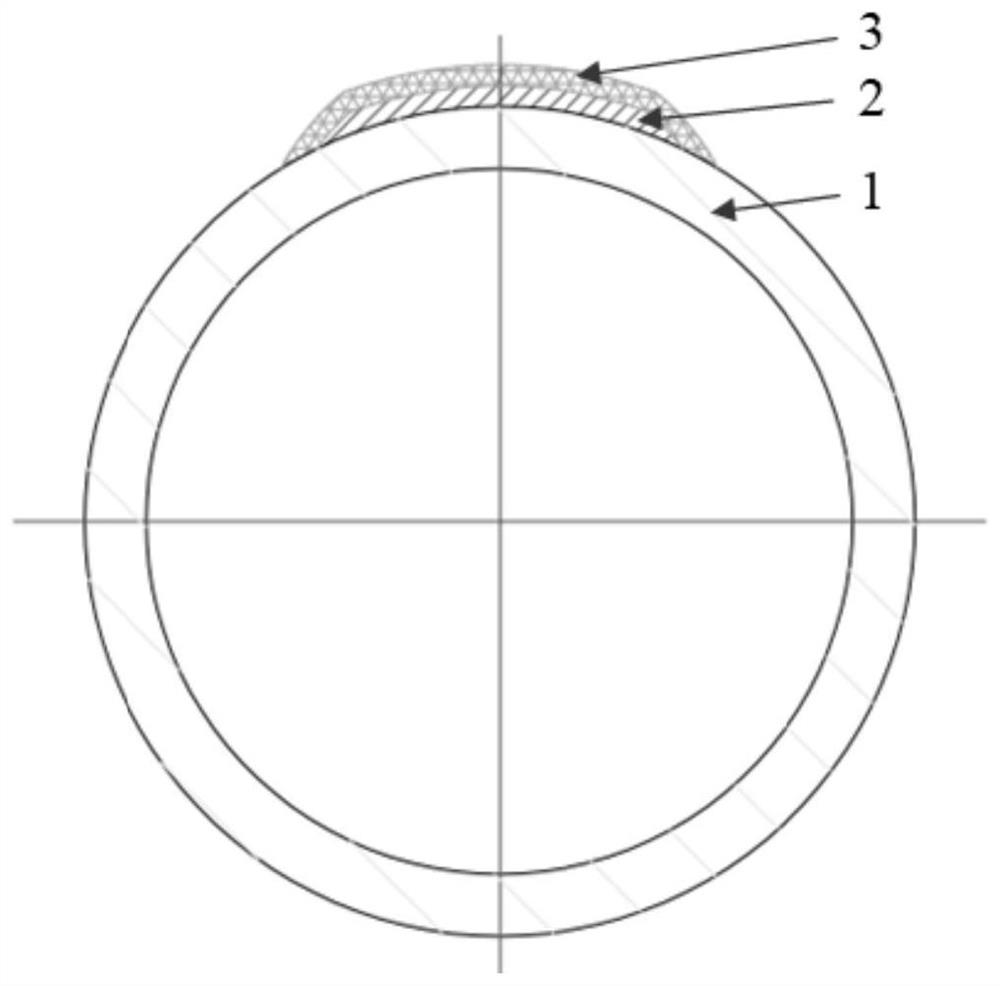

[0029] Such as Figure 1 ~ Figure 2 As shown, a pantograph wear-resistant metal bow angle with an isolation buffer layer is composed of a stainless steel bow angle tube 1, an isolation buffer layer 2, and a wear-resistant coating 3.

[0030] After the surface pretreatment of the pantograph bow angle tube is completed, the nickel-chromium alloy isolation buffer layer is sprayed by supersonic flame spraying technology, with a thickness of 30-60 μm. The preheating temperature of the workpiece before spraying is not greater than 60°C. Within 90~120℃.

[0031] After the workpiece is cooled to room temperature, the nickel-based cermet wear-resistant coating is sprayed on the bow angle isolation buffer layer by supersonic flame spraying technology. The preheating temperature of the workpiece before spraying is not higher than 60°C. Within 90~120℃. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap