Carriage with automatic loading and unloading function

A functional and automatic technology, applied to vehicles with loading and unloading doors, vehicles with loading ramps, loading and unloading vehicle arrangements, etc., can solve the problems of wind and rain, storage, and inability to arrange in different areas, so as to improve utilization efficiency, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

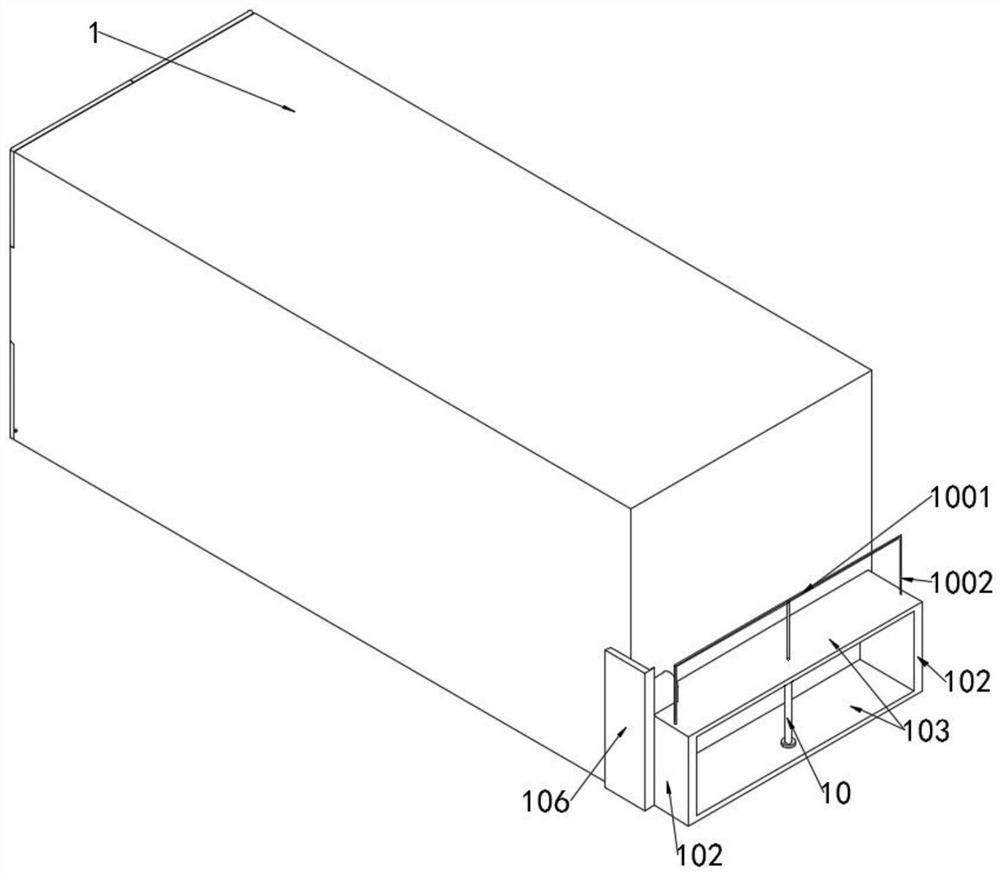

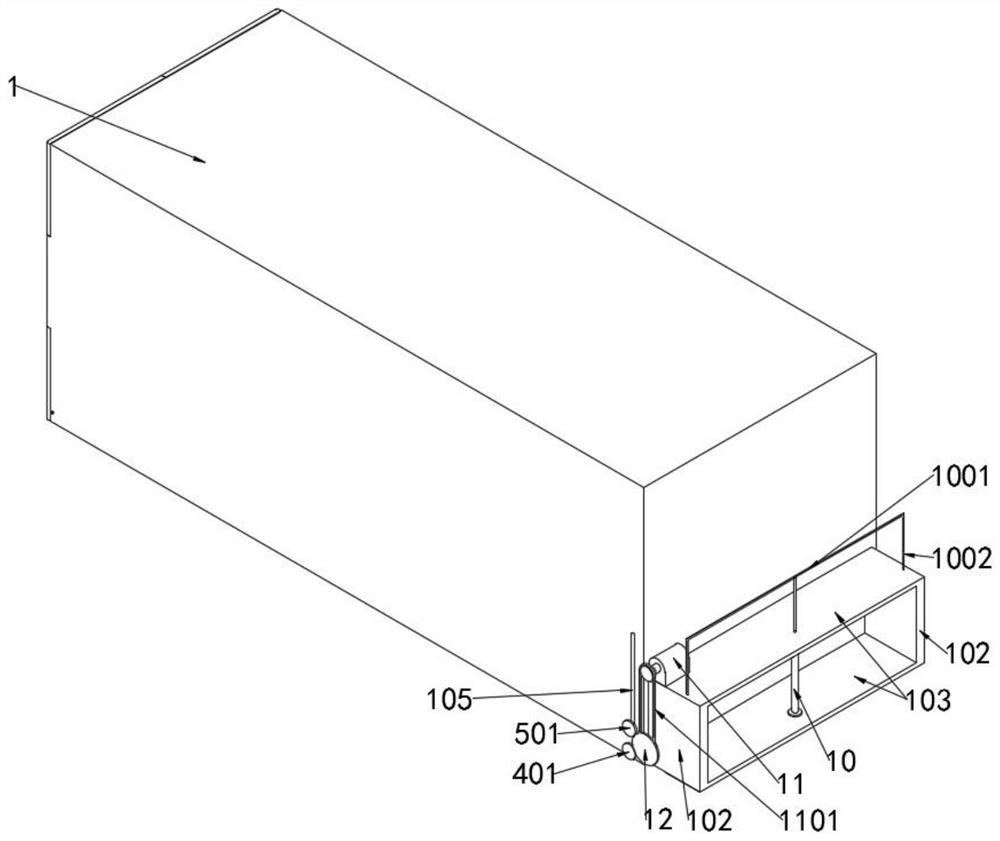

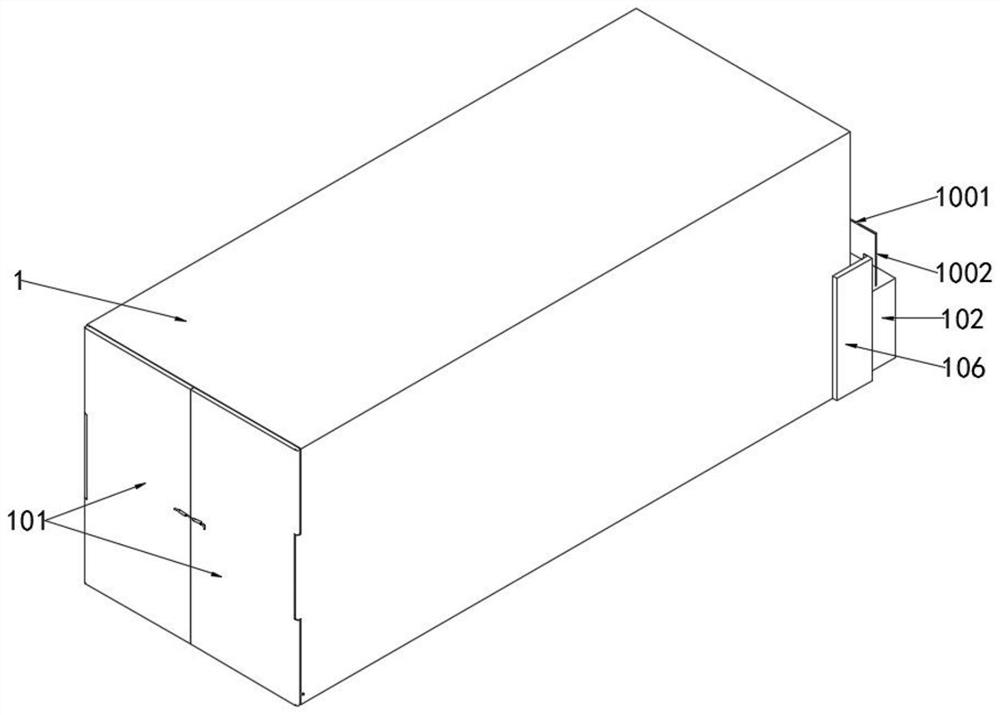

[0046] The accompanying drawing is the best embodiment of the carriage with automatic loading and unloading function, and the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0047] attached by figure 1 , attached image 3 , attached Figure 4 As shown, a carriage with automatic loading and unloading function includes a box body 1, a box door 101 that is rotationally connected at the entrance of the front end of the box body 1, a loading plate 2, a first telescopic device 3, a lower conveyor belt 4, and an upper conveyor belt 5 . Chamber door 101 is a side-by-side chamber door, which adopts the prior art.

[0048] The feeding board 2 is vertically arranged at the entrance of the box body 1, and both ends of the bottom surface of the feeding board 2 are hinged to the side wall of the box body 1. attached by Figure 9 As shown, the end surface of the feeding plate 2 facing the inside of the box body 1 is hinged wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com