Material hoisting carrier for high and low positions

A technology for transporting vehicles and materials, which is applied in hoisting devices, cranes, clockwork mechanisms, etc. It can solve the problems of poor applicability of hoisting machinery, achieve the effects of improving sliding performance, slowing down the damage of wire ropes, and reducing overlapping coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

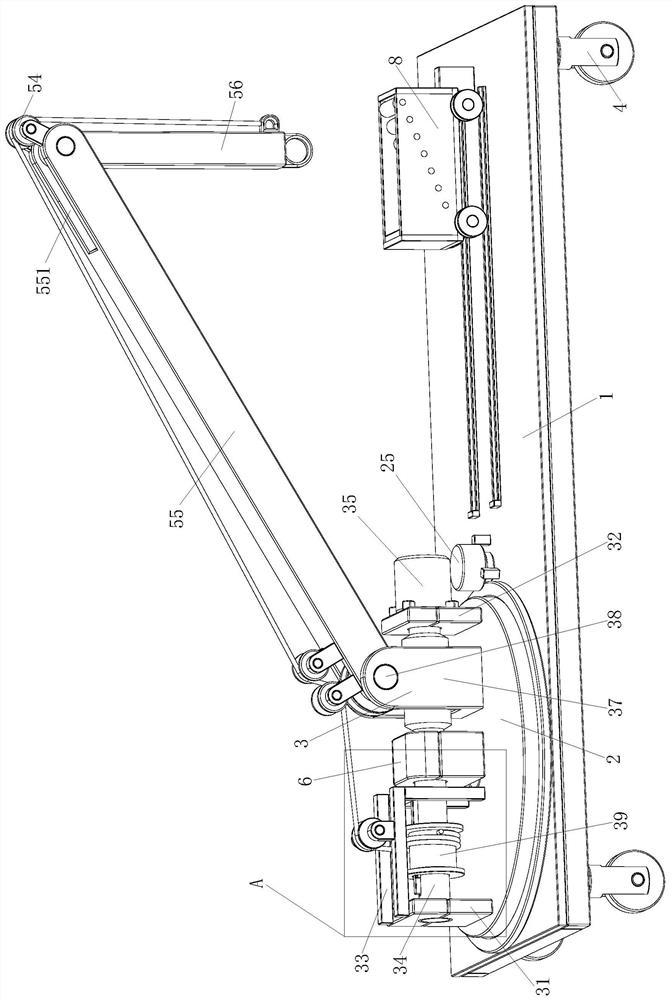

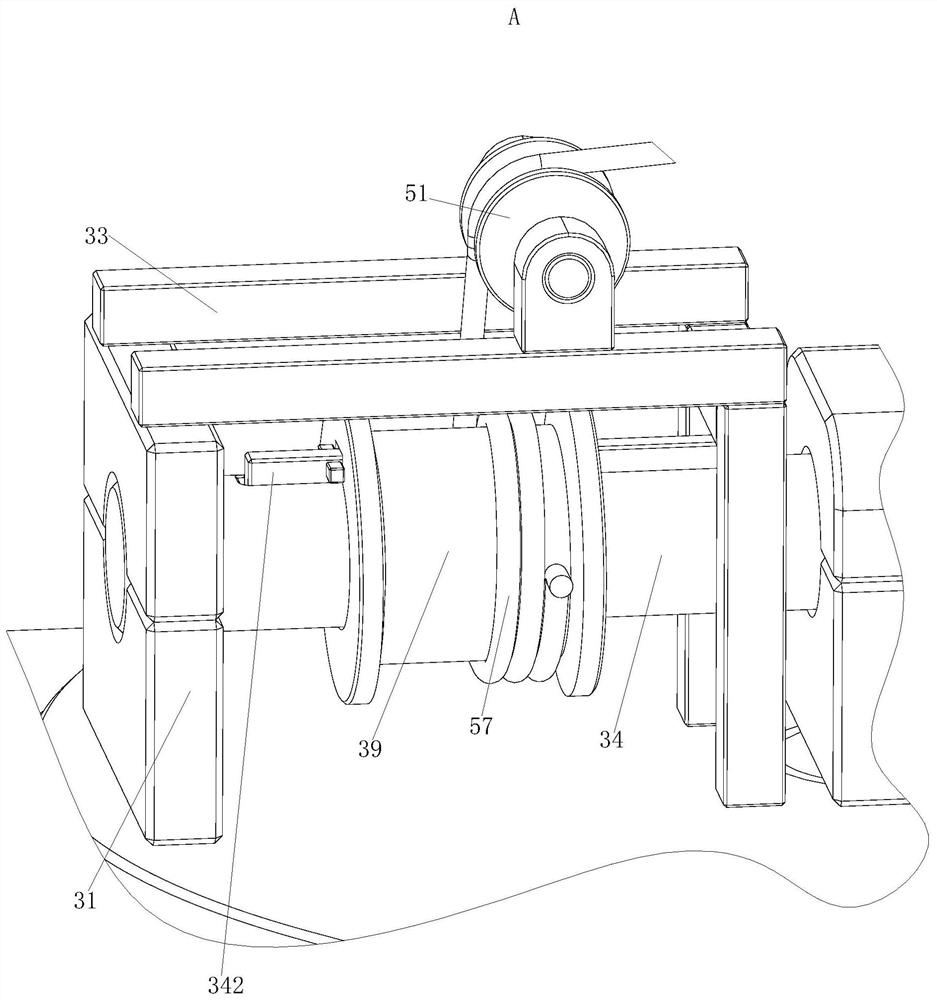

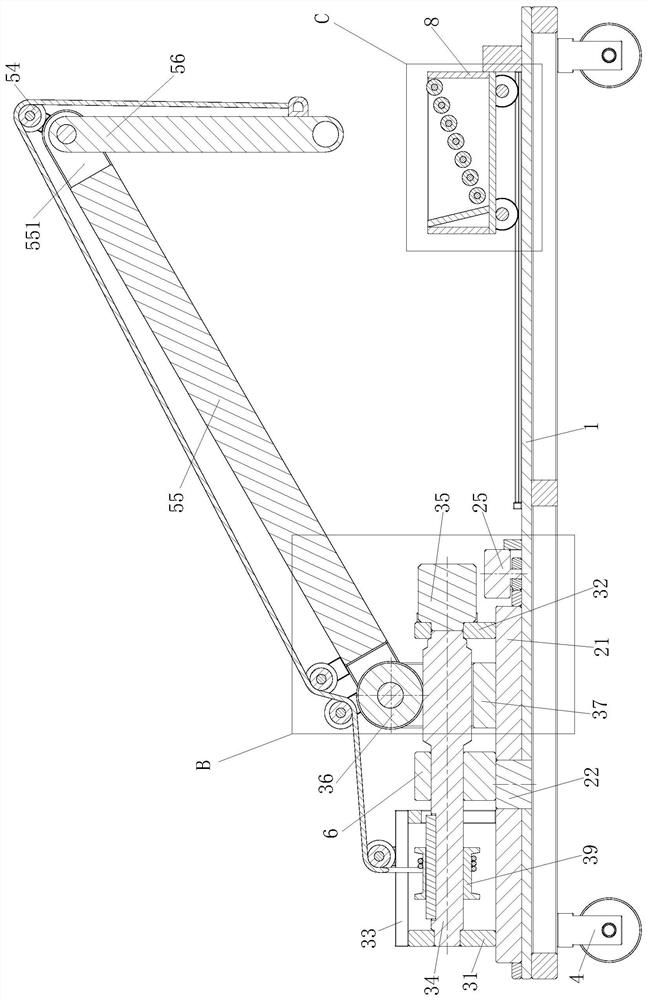

[0037] Such as Figure 1 to Figure 9 As shown, a kind of high and low position material hoisting and transporting vehicle includes a base plate 1, a rotating part 2, a lifting part 3 and a universal wheel 4; the universal wheel 4 is arranged below the base plate 1; the universal wheel 4 is used Supporting and walking on the bottom plate 1; the rotating part 2 is set above the bottom plate 1; the turning part 2 is used for turning the lifting part 3; the lifting part 3 is set above the rotating part 2; the lifting part 3 includes No. 1 side plate 31, No. 2 side plate 32, support frame 33, worm shaft 34, worm gear 36, No. 1 motor 35, reel 39, hinge seat 37, hinge shaft 38, No. 1 fixed pulley 51, No. 2 Fixed pulley 52, No. 3 fixed pulley 53, No. 4 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com