Yttrium-free high-dielectric-constant microwave ferrite material and preparation method and device thereof

A technology of ferrite material and high dielectric constant, which is applied in the field of high dielectric constant microwave ferrite material and its preparation, can solve the problems of unfavorable device application and high insertion loss, reduce the degree of deterioration and increase the dielectric constant , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

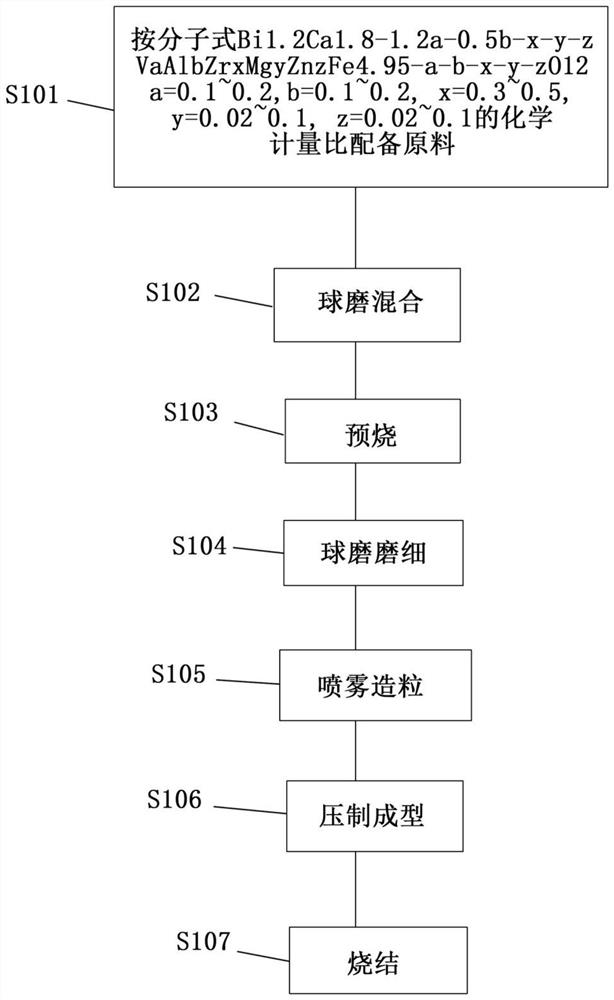

[0056] The preparation method of the high dielectric constant microwave ferrite material of a specific embodiment comprises the following steps:

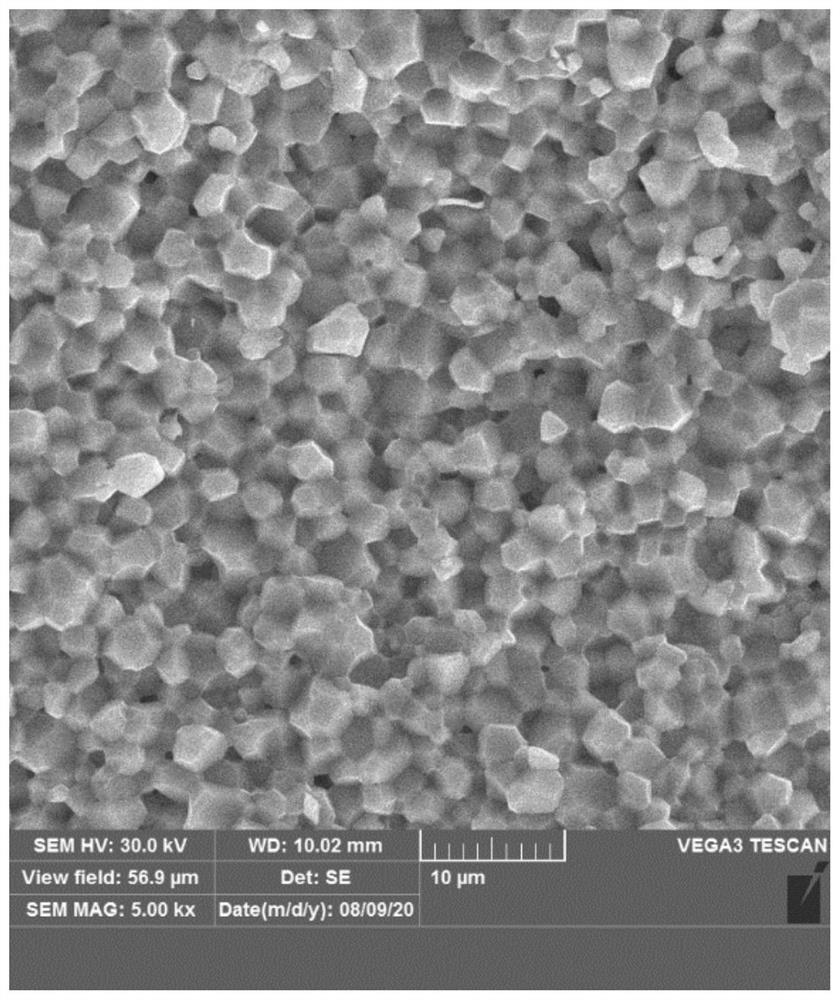

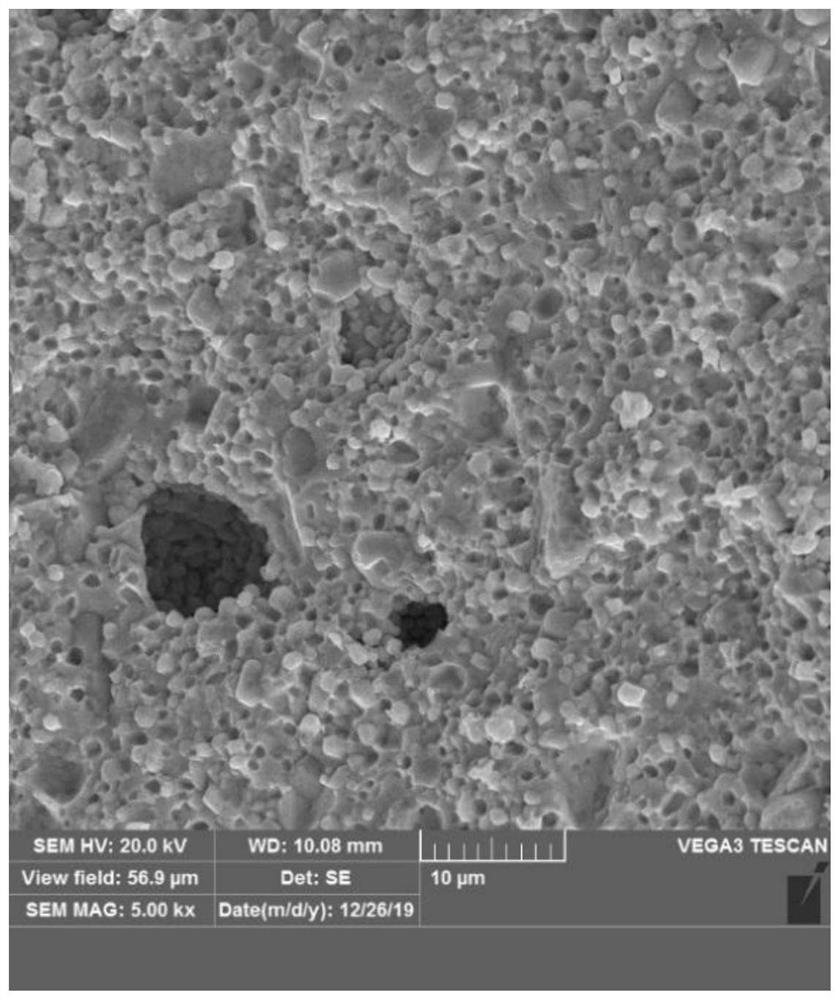

[0057] 1) According to the molecular formula Bi 1.2 Ca 1.8-1.2a-0.5b-x-y-z V a al b Zr x Mg y Zn z Fe 4.95-a-b-x-y-z o 12 (a=0.1-0.2, b=0.1-0.2, x=0.3-0.5, y=0.02-0.1, z=0.02-0.1). The stoichiometric ratio, calculate the ratio of the required raw materials, weigh the raw materials, the corresponding raw materials are respectively Bi 2 o 3 , CaCO 3 , V 2 o 5 、Al 2 o 3 , ZrO 2 , MgO, ZnO, Fe 2 o 3 . Preferably, the raw materials are analytically pure, the MgO and ZnO are nanoscale, the D50 is 100nm-200nm, the MgO and ZnO are nearly spherical in shape, and the specific surface area is 60-70m 2 / g.

[0058] 2) Ball mill mixing: Put the raw materials weighed in step 1) into the ball mill, add the corresponding zirconium balls and pure water according to the ratio of raw materials: zirconium balls: pure water = 1:3.5:1...

Embodiment 1

[0065] According to molecular formula Bi 1.2 Ca 1.29 V 0.1 al 0.1 Zr 0.3 Mg 0.02 Zn 0.02 Fe 4.41 o 12The stoichiometric ratio is calculated, the ratio of the required raw materials is calculated, the raw materials are weighed, and then mixed by ball milling, pre-fired at 850°C for 6 hours, finely milled by ball milling, spray granulated, pressed and formed, and finally sintered at 1060°C and held for 5 hours. A microwave ferrite material is obtained. After testing, the characteristics of the microwave ferrite material are: ε=24.3, 4πMs=1647Gs, ΔH=47Oe, Tc=198°C.

Embodiment 2

[0067] According to molecular formula Bi 1.2 Ca 0.785 V 0.2 Al 0.15 Zr 0.5 Mg 0.1 Zn 0.1 Fe 3.9 o 12 The stoichiometric ratio is calculated, the ratio of the required raw materials is calculated, the raw materials are weighed, and then mixed by ball milling, pre-fired at 750°C for 6 hours, finely ground by ball milling, spray granulation, compression molding, and finally sintered at 1000°C and held for 5 hours. A microwave ferrite material is obtained. After testing, the characteristics of the microwave ferrite material are: ε=25.9, 4πMs=1419Gs, ΔH=46Oe, Tc=206°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com