Device for carrying out high-temperature treatment on carbon black in oxygen-free state

A high-temperature treatment and carbon black technology, applied in the direction of fibrous fillers, etc., can solve the problem of reducing the content of polycyclic aromatic hydrocarbons in carbon black

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

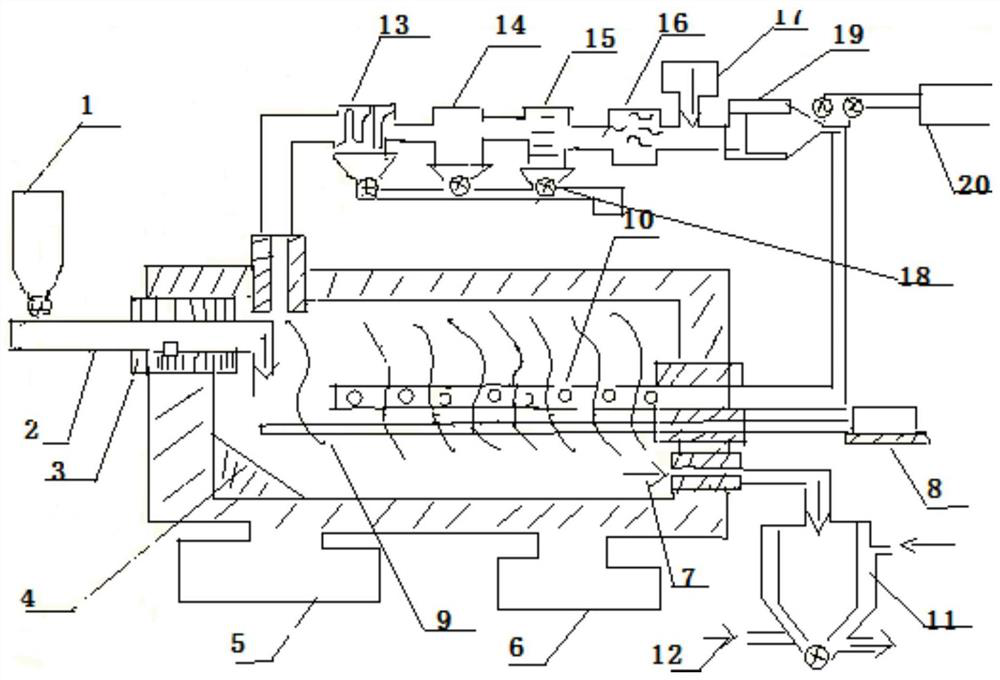

[0034] Such as figure 1 As shown, a device for high-temperature treatment of carbon black is provided in the anaerobic state, including a feed screw 2, a distillation furnace, and a condensation collection device. The discharge end of the feed bin 1 is connected to the feed screw 2 through a regulating valve The feed port is connected, the discharge port of the feed screw 2 is connected to the inlet end of the distillation furnace, the feed screw 2 is sealed and connected with the furnace body, and the distillation furnace 2 includes a furnace cavity, a furnace wall with a jacket and a furnace wall connected to the furnace wall. The first combustion furnace 5 and the second combustion furnace 6, the first combustion furnace 5 and the second combustion furnace 6 provide a certain temperature to the furnace wall by burning natural gas, and the elastic support is designed in the distillation furnace to ensure that the equipment shell is kept at 300°C for a long time. Continuous h...

Embodiment 2

[0037] Such as figure 1As shown, a device for high-temperature treatment of carbon black is provided in the anaerobic state, including a feed screw 2, a distillation furnace, and a condensation collection device. The discharge end of the feed bin 1 is connected to the feed screw 2 through a regulating valve The feed port is connected, the discharge port of the feed screw 2 is connected to the inlet end of the distillation furnace, the feed screw 2 is sealed and connected with the furnace body, and the distillation furnace 2 includes a furnace cavity, a furnace wall with a jacket and a furnace wall connected to the furnace wall. The first combustion furnace 5 and the second combustion furnace 6, the first combustion furnace 5 and the second combustion furnace 6 provide a certain temperature to the furnace wall by burning natural gas, and the elastic support is designed in the distillation furnace to ensure that the equipment shell and body are kept at 300 ° C for a long time Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com