Carbon dioxide adsorption recovery method

A carbon dioxide, adsorption and recovery technology, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve the problems of serious waste residue and poor carbon dioxide adsorption effect, and achieve recycling and production costs. Inexpensive, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of octavinylsilsesquioxane Add 30 mL of vinyltriethoxysilane, 100 mL of acetone, 80 mL of concentrated hydrochloric acid and 80 mL of distilled water into a 500 mL round bottom flask in sequence. Stir at room temperature for 72 h, filter with suction, wash the filter cake with acetone and methanol several times, and dichloromethane and ethanol solution (V 二氯甲烷 / V 乙醇 =1:1) and dried under vacuum at 60 °C for 24 h to obtain octavinylsilsesquioxane.

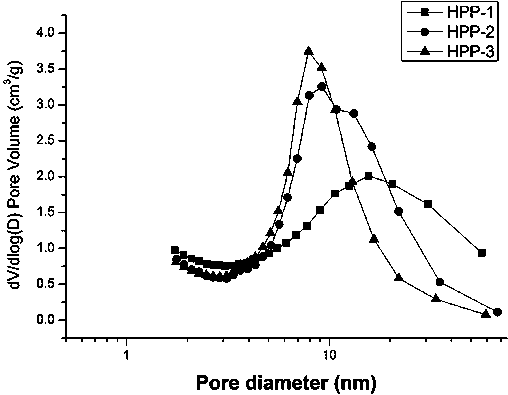

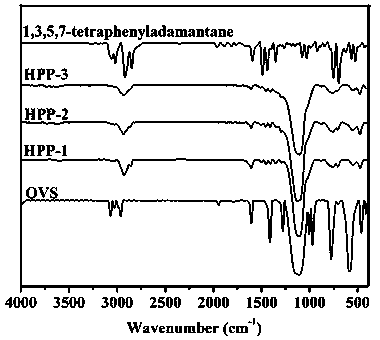

[0045] (2) Adamantyl porous polymer: in N 2 In a 50 mL round bottom flask, add 1.00 g 1,3,5,7-tetraphenyladamantane, 1.44 g octavinylsilsesquioxane, 1.22 g anhydrous AlCl 3 and 20 mL of 1,2-dichloroethane, magnetically stirred for 1 h, heated to 80 °C and kept at this temperature for 24 h, filtered with suction, washed with anhydrous methanol successively, and then placed in a Soxhlet extractor, respectively The adamantyl porous polymer HPP-1 was obtained by using methanol and 1,2-dichloromethane as solvent...

Embodiment 2

[0049] (1) Preparation of octavinylsilsesquioxane Add 30 mL of vinyltriethoxysilane, 100 mL of acetone, 80 mL of concentrated hydrochloric acid and 80 mL of distilled water into a 500 mL round bottom flask in sequence. Stir at room temperature for 72 h, filter with suction, wash the filter cake with acetone and methanol several times, and dichloromethane and ethanol solution (V 二氯甲烷 / V 乙醇 =1:1) and dried under vacuum at 60 °C for 24 h to obtain octavinylsilsesquioxane.

[0050] (2) Adamantyl porous polymer: in N 2 Under atmosphere, add 1.00 g 1,3,5,7-tetraphenyladamantane, 2.35 g octavinylsilsesquioxane, 1.00 g anhydrous AlCl to a 50 mL round bottom flask 3 and 20 mL of 1,2-dichloroethane, magnetically stirred for 1 h, heated to 80 °C and kept at this temperature for 24 h, filtered with suction, washed with anhydrous methanol successively, and then placed in a Soxhlet extractor, Purified with methanol and 1,2-dichloromethane as solvents for 48 h respectively, and dried in v...

Embodiment 3

[0053] (1) Preparation of octavinylsilsesquioxane Add 30 mL of vinyltriethoxysilane, 100 mL of acetone, 80 mL of concentrated hydrochloric acid and 80 mL of distilled water into a 500 mL round bottom flask in sequence. Stir at room temperature for 72 h, filter with suction, wash the filter cake with acetone and methanol several times, and dichloromethane and ethanol solution (V 二氯甲烷 / V 乙醇 =1:1) and dried under vacuum at 60 °C for 24 h to obtain octavinylsilsesquioxane.

[0054] (2) Adamantyl porous polymer: in N 2 Under atmosphere, add 1.00 g 1,3,5,7-tetraphenyladamantane, 2.88 g octavinylsilsesquioxane, 0.63 g anhydrous AlCl to a 50 mL round bottom flask 3 and 20 mL of 1,2-dichloroethane, magnetically stirred for 1 h, heated to 80 °C and kept at this temperature for 24 h, filtered with suction, washed with anhydrous methanol successively, and then placed in a Soxhlet extractor, Purified with methanol and 1,2-dichloromethane as solvents for 48 h respectively, and dried in v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com