Integrated treatment device for ship waste gas

A treatment device and oxidation device technology, applied in the direction of gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of low removal efficiency, difficult operation and maintenance, serious secondary pollution, etc., achieve high-efficiency reaction, save water Effects of treatment piping layout, efficient adsorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

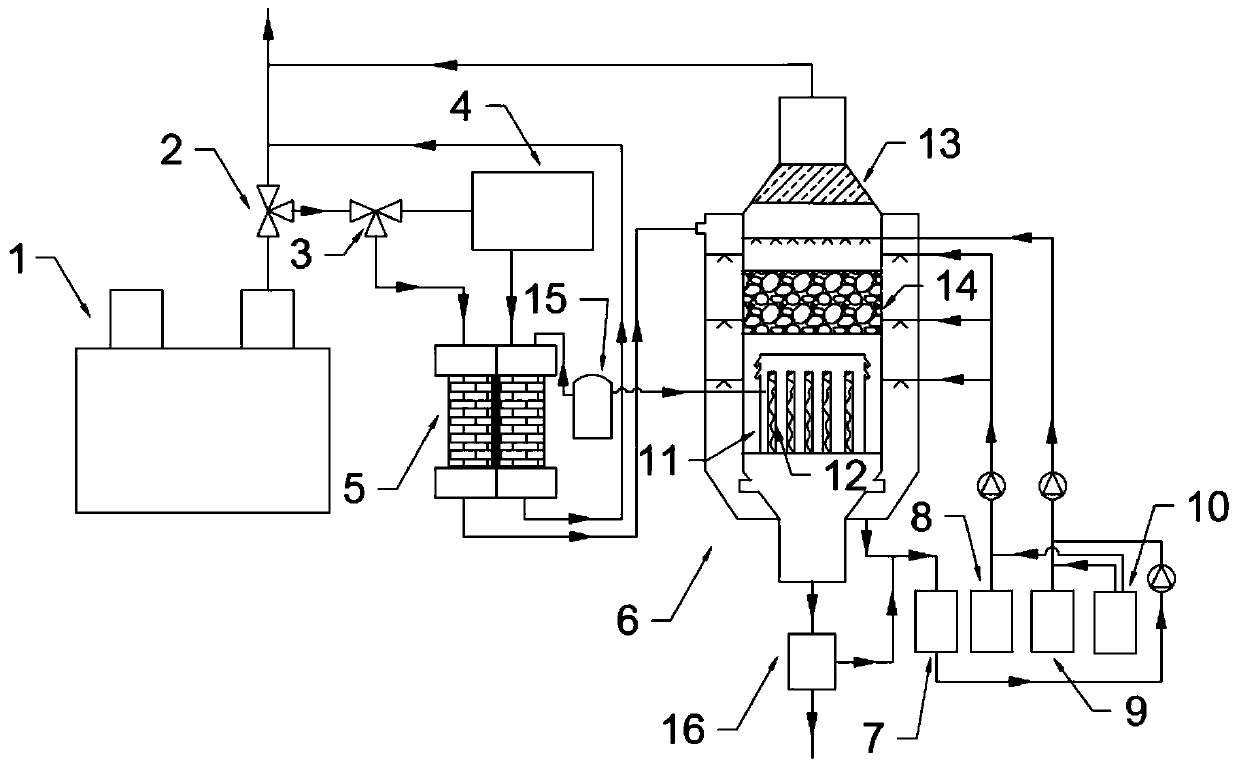

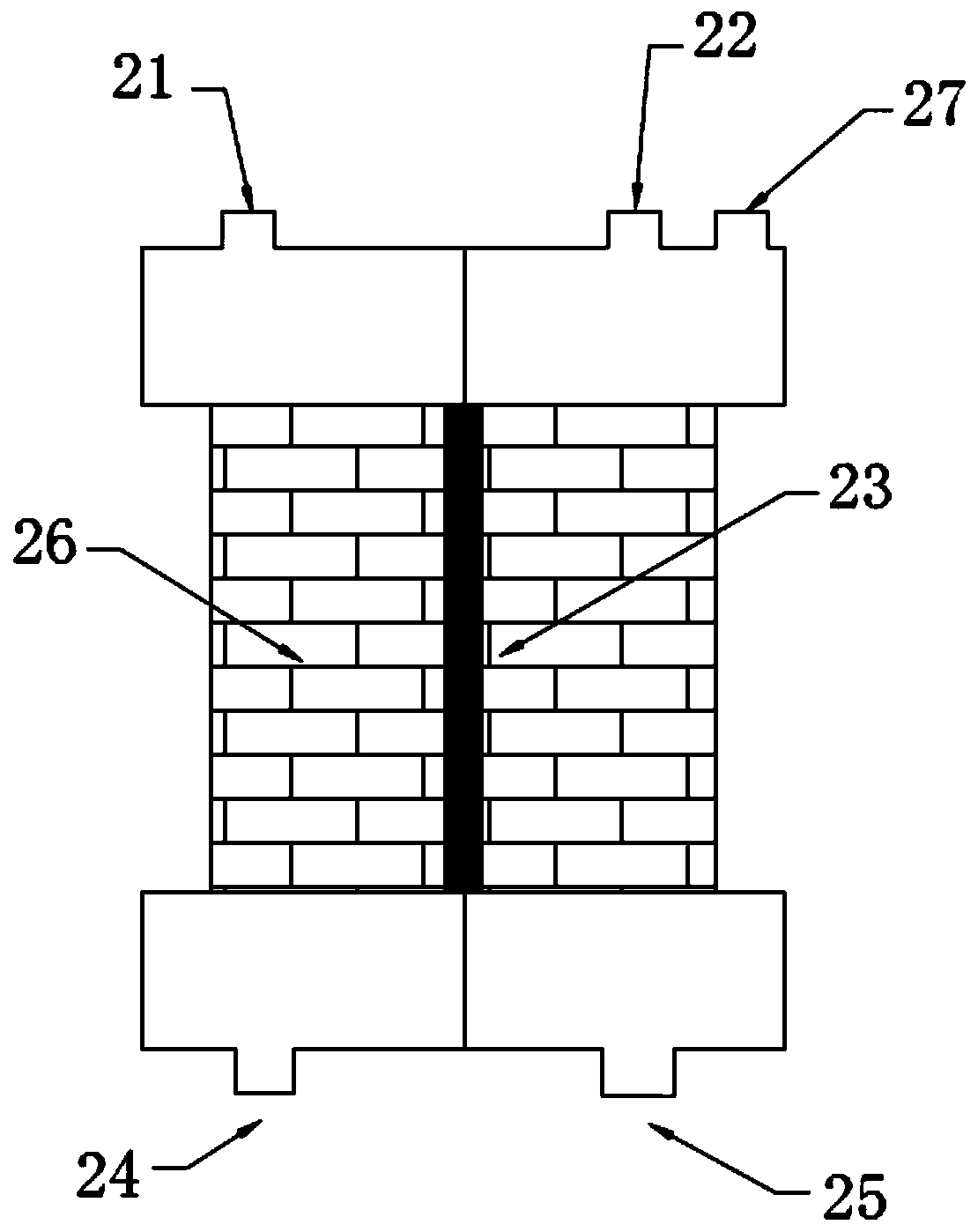

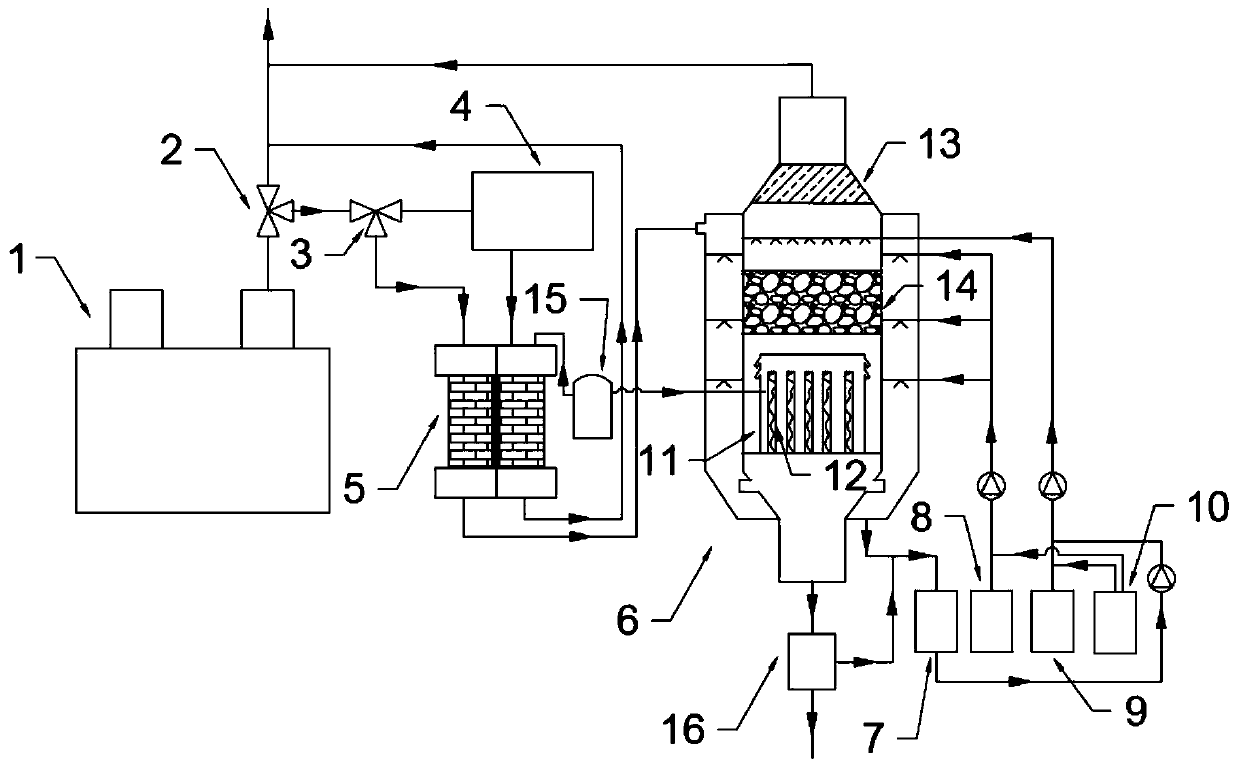

[0025] combine Figure 1-2 , the present invention mainly includes a pollutant adsorption device 5 , a waste heat recovery system (WHR) 4 , a washing tower 6 , an air bottle 15 and a NO oxidation device 11 . Utilize pollutant adsorption device 5 to NO and SO in waste gas 2 For enrichment, the adsorbent includes molecular sieve, Al 2 o 3 and so on for NO and SO 2 substances to be adsorbed. Utilize Na 2 SO 3 The solution and the washing waste liquid produced by desulfurization are used together as the washing liquid for denitrification, realizing the transformation of waste into treasure. The NO is oxidized by intermittently working ultraviolet rays and the air supplied by the air bottle, and the oxidation rate is relatively high. Use the waste heat recovery system (WHR) to reduce the temperature of the exhaust gas, and use the adsorbent to remove NO and SO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com