A kind of toughness meltblown non-woven fabric manufacturing equipment

A technology of melt-blown non-woven fabrics and manufacturing equipment, which is applied in the direction of melt-spinning, textiles, papermaking, non-woven fabrics, etc., and can solve problems such as blockage of materials in the nozzle head, and achieve the effects of solving blockages, ensuring cleanliness, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

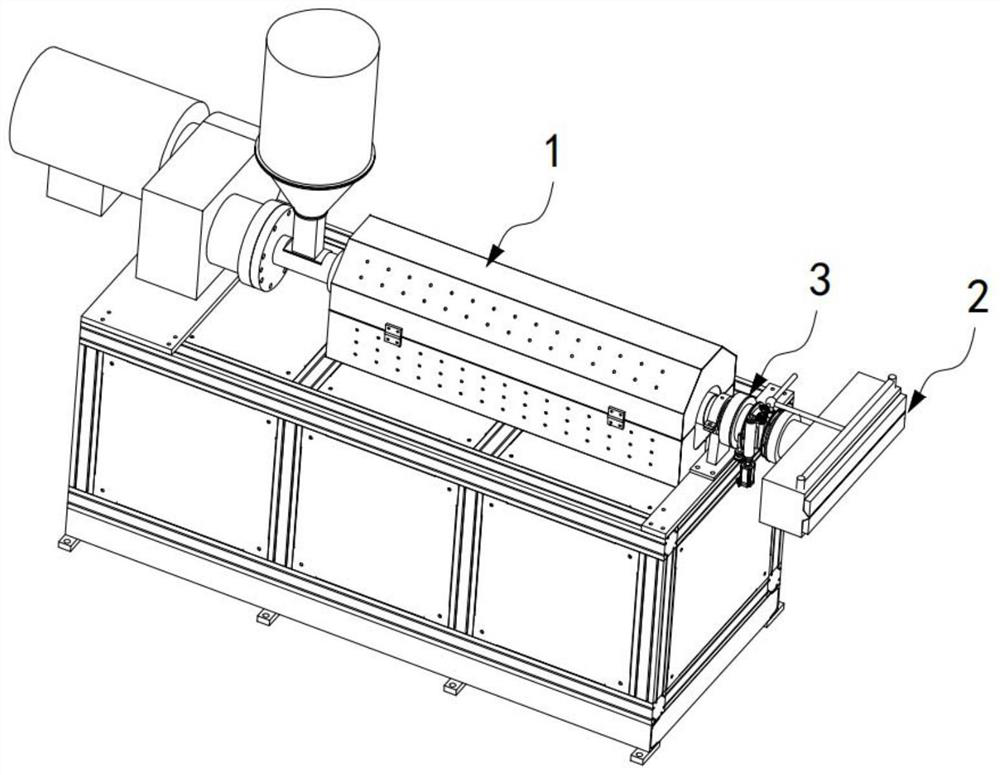

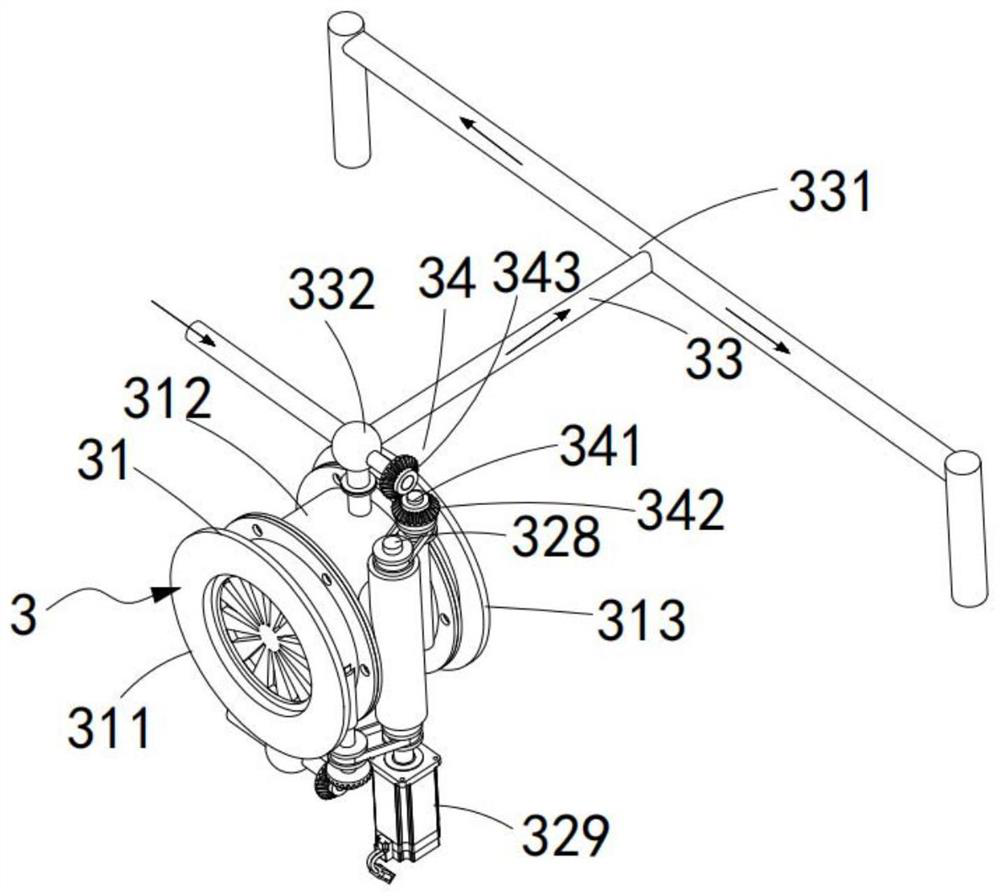

[0057] like Figures 1 to 10 As shown, a kind of toughness melt-blown non-woven fabric manufacturing equipment, including screw extrusion device 1 and spray head 2 that are connected, and the non-woven raw material is screwed to the spray head 2 through the screw extrusion device 1. sprayed, also includes:

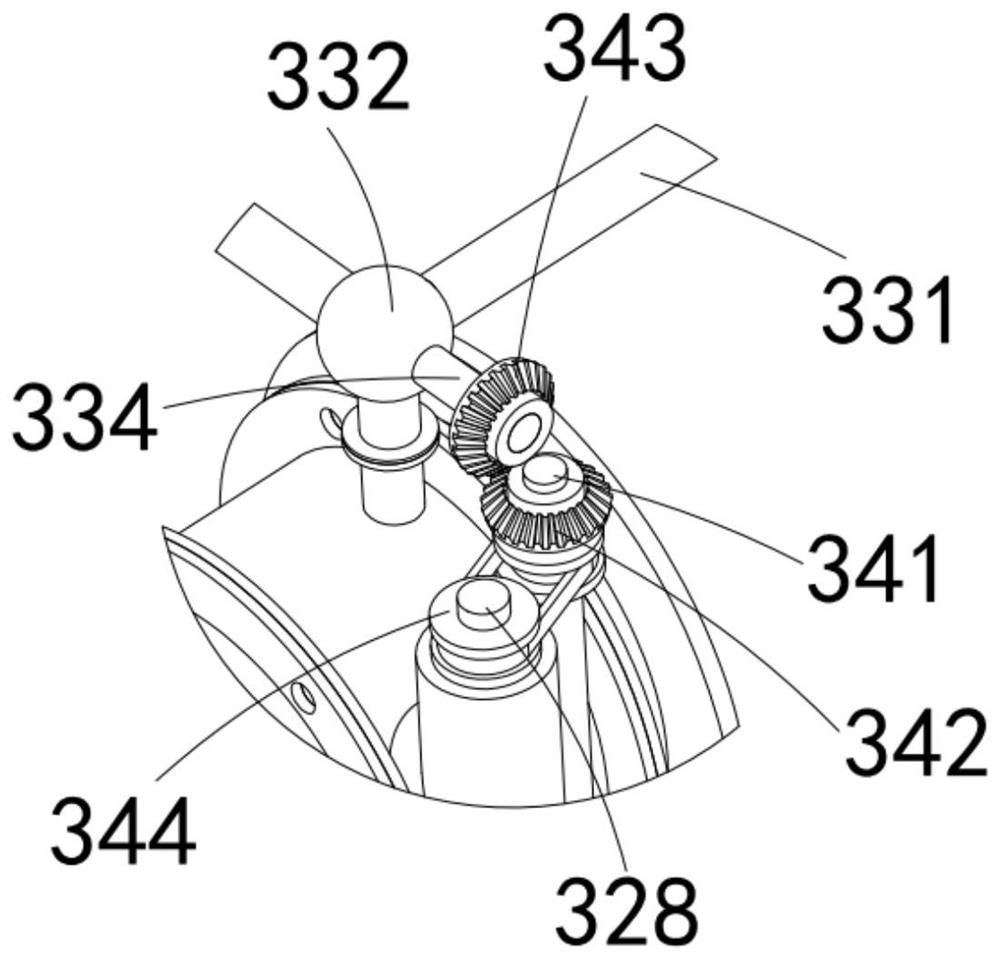

[0058] Cleaning assembly 3, the cleaning assembly 3 includes an outer cylinder group 31, an inner cylinder group 32 and an air scavenging mechanism 33, the two ends of the outer cylinder group 31 are respectively connected with the screw extrusion device 1 and the material spraying The head 2 is installed and connected, the inner cylinder group 32 is coaxially arranged inside the outer cylinder group 31, and an annular airtight channel 30 is formed between it and the outer cylinder group 31, and the air scavenging mechanism 33 is installed in the On the outer wall of the outer cylinder group 31, it communicates with the airtight passage 30. When the inner cylinder group 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com