Net forming structure and process of melt-blown cloth

A melt-blown cloth and net-forming technology, which is applied in the field of textile manufacturing, can solve problems such as low product quality and poor drafting effect, and achieve good performance, improved drafting effect, and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

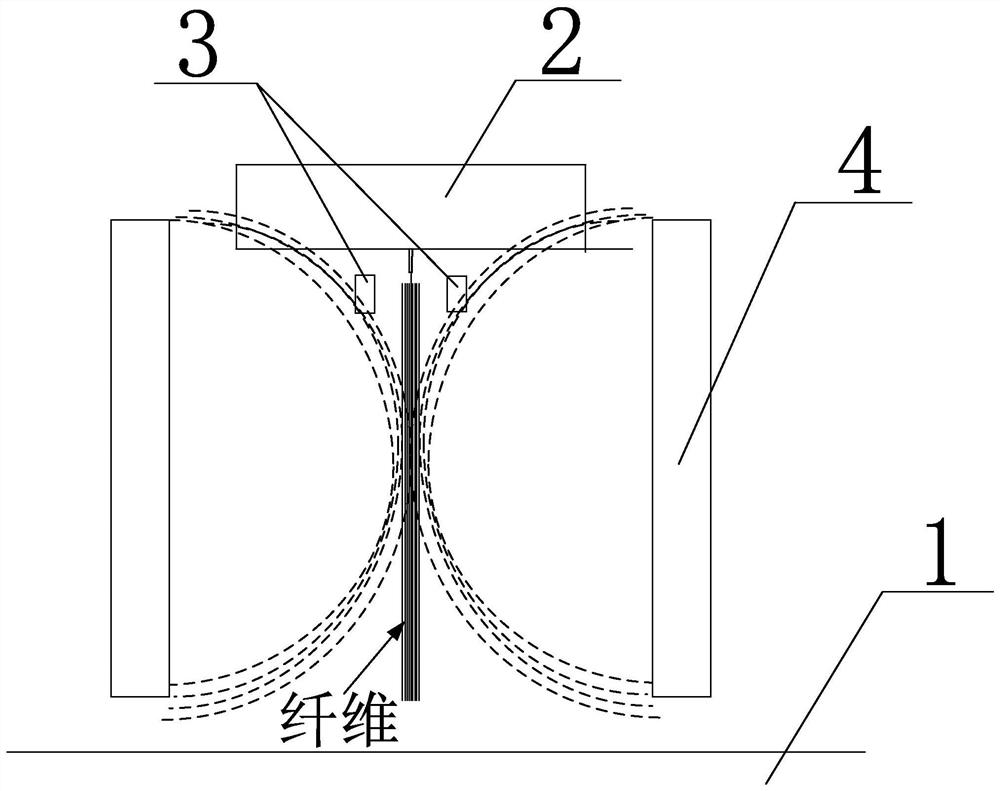

[0022] Such as figure 1 As shown, a web-forming structure of a melt-blown cloth includes a spinneret 2 with a hot air drafting function arranged above the web-forming curtain 1. It is characterized in that the spinneret holes below the spinneret 2 are arranged on both sides There is an electrostatic electret machine 3, and a magnet 4 is arranged between the spinneret 2 and the web-forming curtain 1. The direction of the Lorentz force generated by the magnetic field of the magnet 4 on the fibers is consistent with the direction of movement of the spinneret fibers.

[0023] The web-forming structure of the present invention, by constructing a spatial magnetic field in the spinning area, when the fiber is ejected from the spinneret hole, uses hot air and a magnetic field to simultaneously draft the fiber, which can greatly improve the drafting effect, thereby achieving improved product filtration. effective purpose. The invention utilizes the principle of electromagnetic mutual ...

Embodiment 2

[0028] A web forming process of melt-blown cloth. The fibers are sprayed from the spinneret, and the hot air of the spinneret is used to initially draw the fibers, and the electrostatic electret machine is started to make the sprayed fibers charged and charged. When passing through the magnetic field of the magnet, a vertically downward Lorentz force is generated, and the fiber is double-drawn by the blowing force of the hot air and the Lorentz force of the magnetic field.

[0029] The web-forming process of the present invention adopts the drafting method combining hot air and magnetic field, which can not only avoid the mutual contact and entanglement of fibers, overcome the defects of hot air drafting alone, but also improve the drafting effect, so that the fibers can be It is fully stretched to become finer and improve the quality of web formation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com