Low-noise axial flow fan

An axial flow fan and low noise technology, applied in axial flow pumps, mechanical equipment, machines/engines, etc., can solve the problems of high noise and difficult heat dissipation of motors, and achieve the effect of improving heat dissipation performance and shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

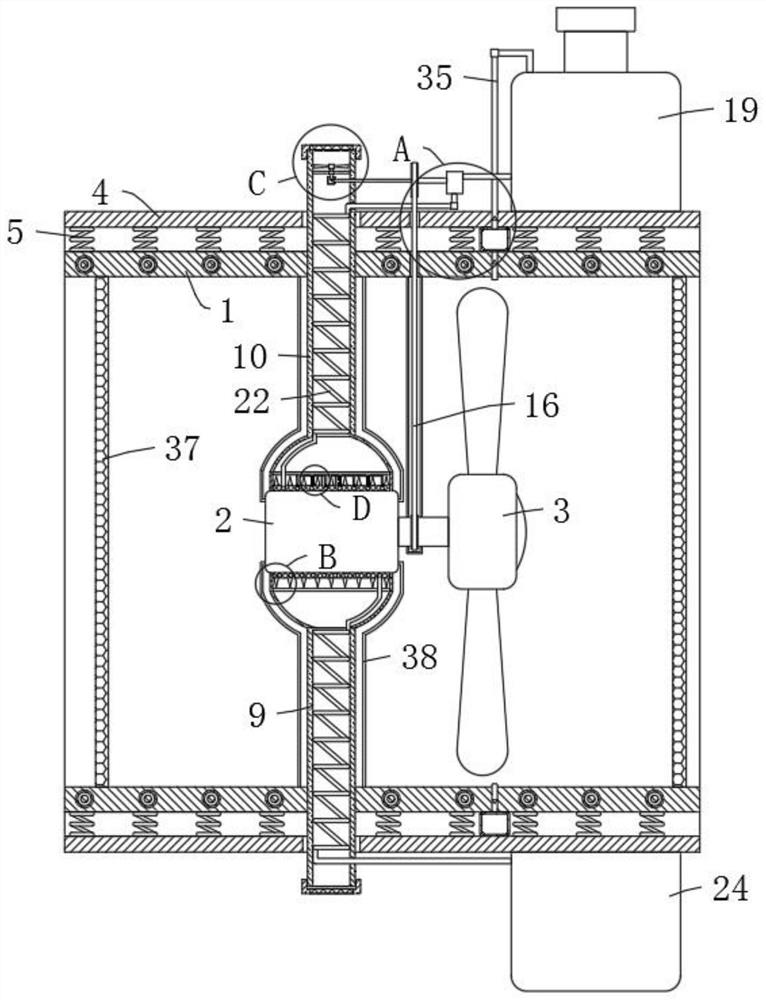

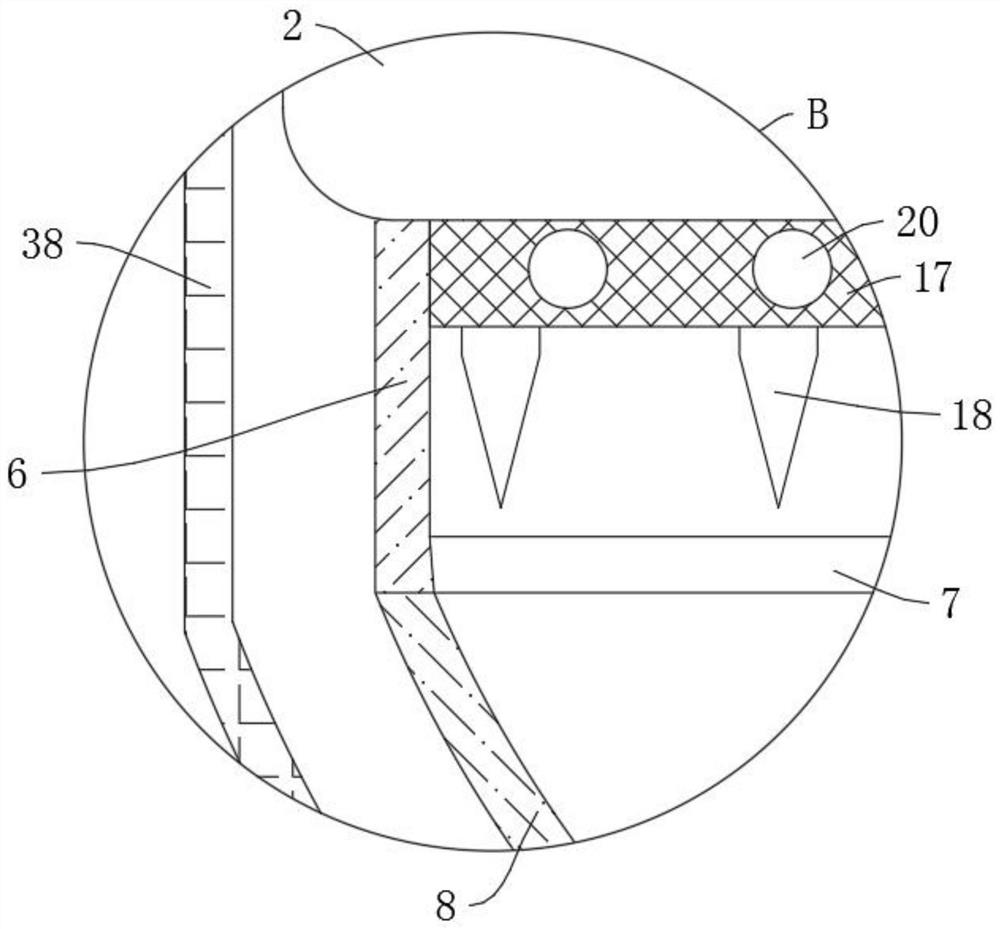

[0032] refer to Figure 1-6 , a low-noise axial flow fan, including an inner cylinder 1, a motor 2 is fixedly installed inside the inner cylinder 1 through a bracket, safety nets 37 are fixedly installed at both ends of the inner cylinder 1, and the end of the output shaft of the motor 2 The fan blade 3 is fixedly installed, the outer wall of the inner cylinder 1 is covered with an outer cylinder 4, the inner cylinder 1 and the outer cylinder 4 are elastically connected by a plurality of evenly distributed buffer springs 5, and the circumference of the motor 2 The outer wall fixing sleeve is provided with an air collecting cylinder 6, the upper and lower ends of the air collecting cylinder 6 are fixedly connected with the air collecting hood 8, and the upper and lower ends of the air collecting cylinder 6 are provided with ventilation slots corresponding to the air collecting hood 8 7. The inlet ends of the two wind collecting hoods 8 are respectively fixedly connected with th...

Embodiment 2

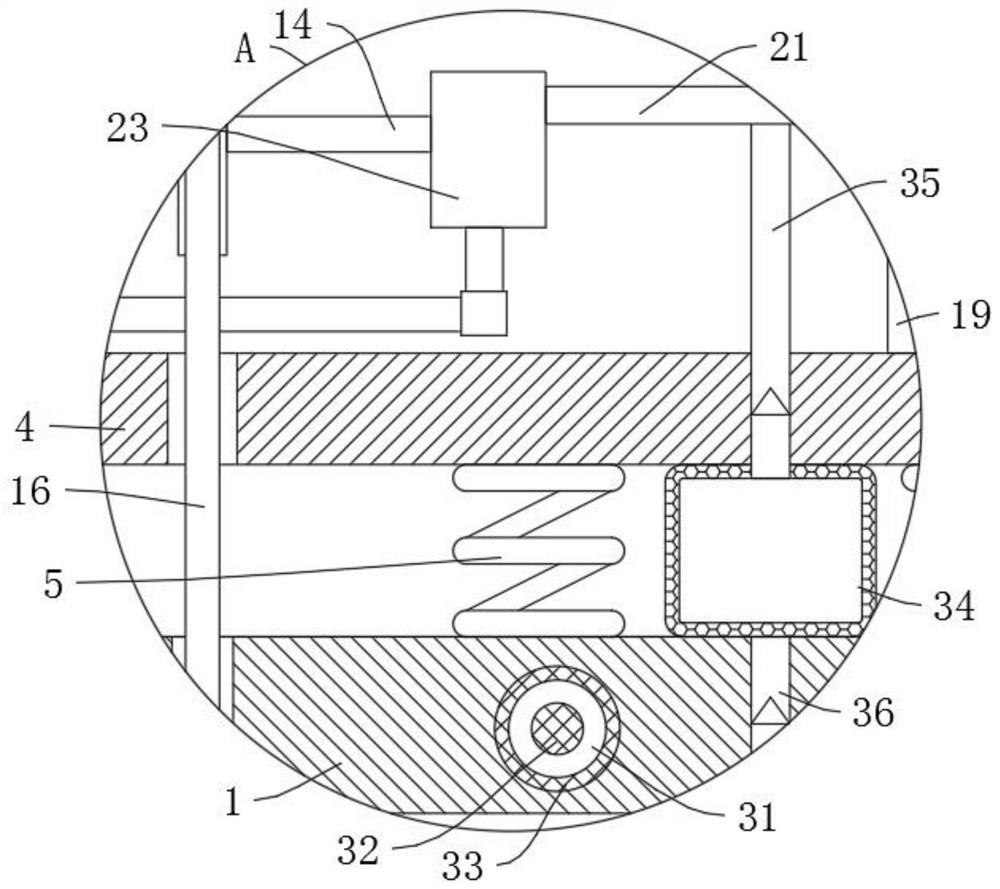

[0037] refer to figure 1 and Figure 4 , is basically the same as Embodiment 1, furthermore: the ventilation device includes a rotating rod 12 connected in the air inlet pipe 10 through a cross bar 11, the upper end of the rotating rod 12 is fixedly connected with a ventilation fan blade 13, and the air inlet pipe 10 The side wall of the drive shaft 14 is rotatably connected to the drive shaft 14, the left end of the drive shaft 14 is meshed with the lower end of the rotating rod 12 through two gears 15, and the other end of the rotating rod 12 is connected to the output shaft of the motor 2 through a chain drive 16. , the motor 2 will also drive the transmission shaft 14 to rotate through the chain transmission 16, and the transmission shaft 14 will also drive the input shaft of the water pump 23 to rotate, so the water pump 23 will pump the water in the upper water tank 19 into the lower water tank 24 through the delivery pipe 21, and then transport During this period, the ...

Embodiment 3

[0039] refer to Figure 1-3 and Figure 6 , is basically the same as Embodiment 1, furthermore: the water circulation device includes a heat conduction cylinder 17 fixedly connected to the outer wall of the motor 2, the heat conduction cylinder 17 is fixedly connected with a first helical tube 20, and the two ends of the first helical tube 20 Both are connected with delivery pipes 21, and the other ends of the two delivery pipes 21 are fixedly connected with the upper water tank 19 and the lower water tank 24 respectively. The middle part of the delivery pipe 21 on the side wall of the water tank 19 is fixedly equipped with a water pump 23, and the right end of the transmission shaft 14 is connected with the water pump 23. The input shaft of the upper water tank 19 and the lower water tank 24 are fixedly connected and communicated through a plurality of connecting pipes 25, an emergency cooling device is arranged between the heat conduction cylinder 17 and the first spiral pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com