Water-based paint mixing tank

A water-based paint and paint mixing technology, which is applied in the field of water-based paint mixing tanks, can solve the problems of water-based paint shear damage, blockage of pipelines, and damage to the stability of water-based paint in the pipeline cycle, so as to solve pipeline blockage and solve pipeline problems. Clogging, reducing the effect of shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

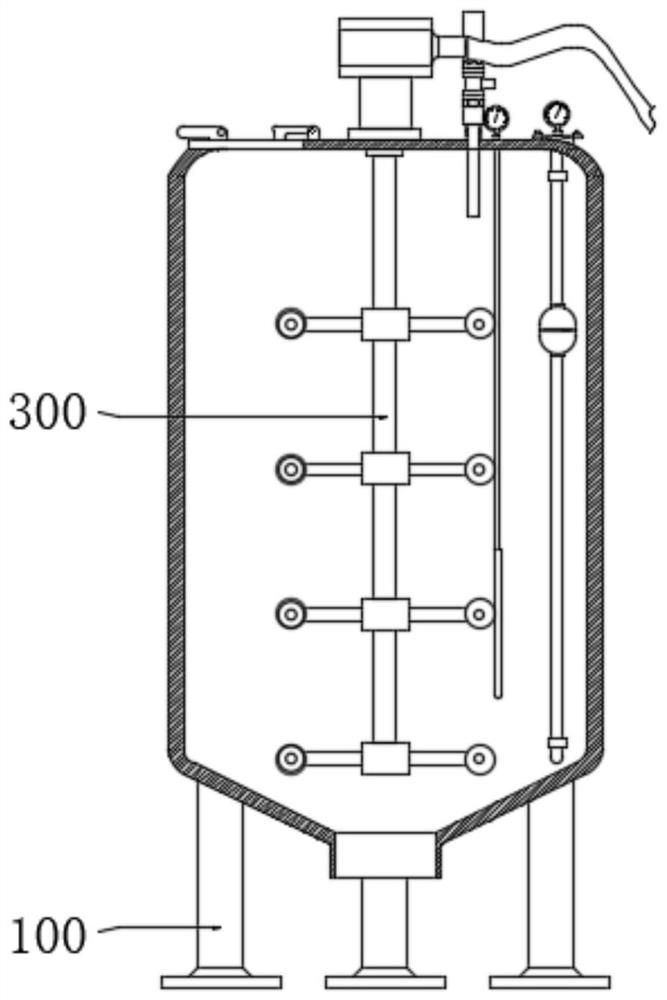

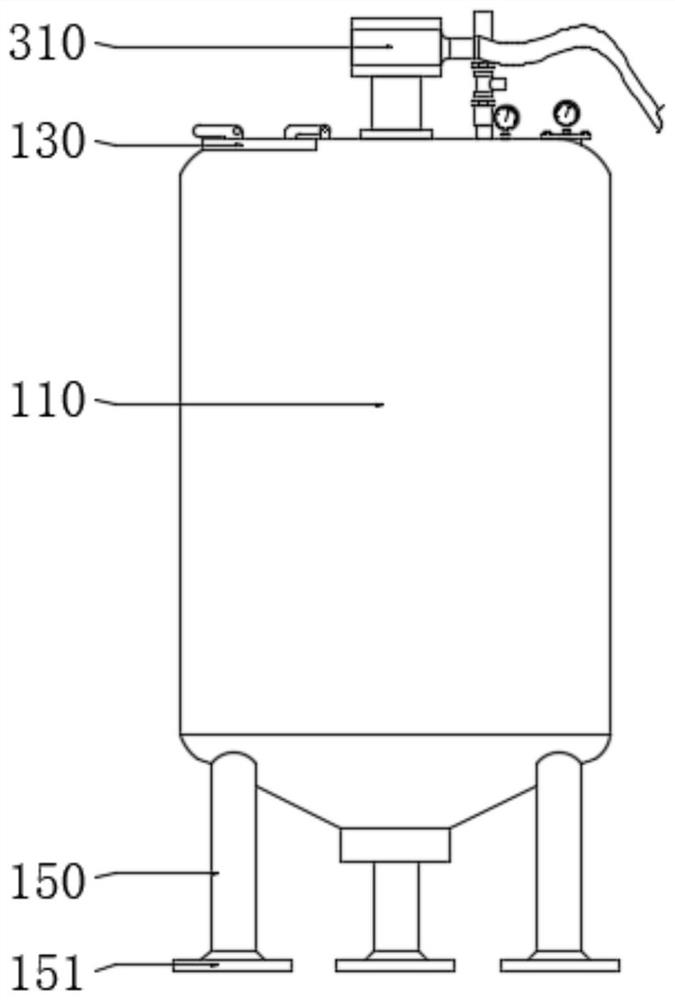

[0034] see Figure 1-5 , the present invention provides a water-based paint mixing tank comprising a machine body 100 and a stirring assembly 300 .

[0035] Among them, the stirring assembly 300 is rotatably connected to the body 100. The body 100 is used to assemble and fix the mechanisms of different functional structures, making it a whole, which is convenient for personnel to operate and improve work efficiency. The stirring assembly 300 is used to stir the water-based paint evenly, which is convenient Proceed to subsequent spraying operations.

[0036] see Figure 1-4 , the machine body 100 includes a tank body 110 .

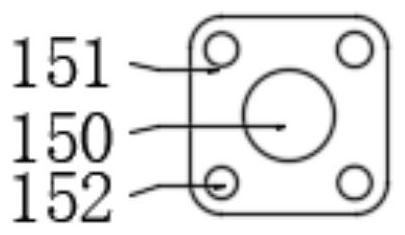

[0037] In some specific embodiments, a feed port 111 is provided on the upper side of the tank body 110, which is convenient for feeding materials into the tank body 110, and an openable cover 130 is hinged and fixed on the side of the tank body 110 close to the feed port 111, which is convenient for opening and closing. To prevent dust and impurities fr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap