A high-temperature and high-pressure reactor for in-situ optical measurement of a large-capacity liquid environment

A liquid environment, optical measurement technology, used in color/spectral property measurement, measurement device, material analysis by optical means, etc., can solve problems such as inability to observe substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 Overall structure of the present invention

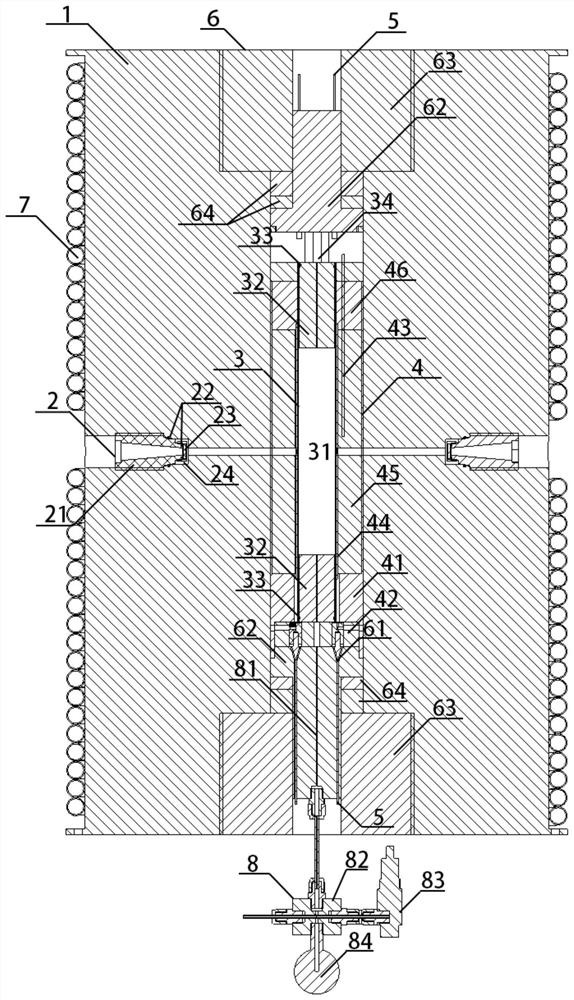

[0017] Such as figure 1 As shown, it is a large-capacity liquid environment in-situ optical measurement high-temperature and high-pressure reactor capable of in-situ optical measurement. Its structure includes a reactor body 1, an optical window part 2, a sample chamber assembly 3, and a heating body assembly 4. Electrode 5, sealing part 6, water cooling tube 7, pressure component 8

[0018] The reactor body 1 of the reaction kettle adopts a cylindrical shape as a whole, and a hollow cavity inside. The diameter of the reactor body is 412 mm, and the height is 645 mm. 4340 alloy steel or other steels with comparable properties are selected as materials. In this embodiment, the pressure The container wall thickness is 152.4mm. Three circular windows with a diameter of 4 mm are provided at a vertical angle in the middle of the kettle body 1 for placing optical window parts 2, two of which are coaxial, and the othe...

Embodiment 2

[0022] Example 2 The working process of using the device of the present invention to perform in-situ measurement of high-temperature and high-pressure liquid environments

[0023] (1) Inject the sample into the sample chamber, seal the two ends of the sample chamber with sealing pistons, slide the sealing piston to make the volume of the sample chamber consistent with the volume of the sample, ensure that the pressure inside and outside the sample chamber is consistent during the pressurization process, assemble the sample chamber components, and The upper sealing part is connected;

[0024] (2) Assembling the heating body assembly, inserting the sample chamber assembly into the heating body assembly and connecting it with the lower sealing part;

[0025] (3) Put the assembled upper sealing part, sample chamber assembly, heating body assembly and lower sealing part into the inner cavity of the reaction kettle from the opening at the bottom of the reaction kettle, and gradually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com