High-contrast x-ray pseudoheat source based on coded metal aperture array plate

A high-contrast, metal hole technology, applied in the field of X-ray light sources, can solve the problems of short X-ray wavelength, short coherence time, and the impact of intensity-related imaging quality, and achieve high contrast and improve the effect of speckle contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

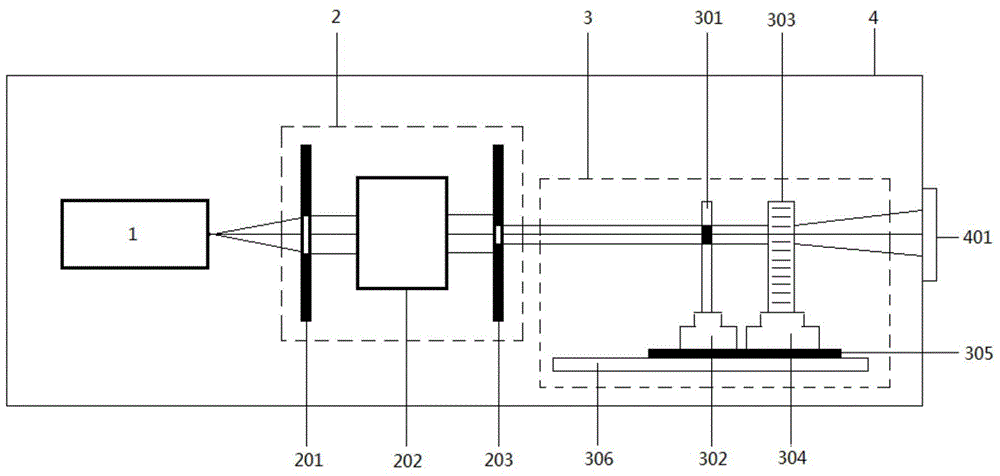

[0042] The present invention is based on the high-contrast X-ray pseudoheat source of coded metal hole array plate, including: X-ray generator 1, X-ray transmission modulation system 2, pseudothermal X-ray generation system 3, radiation-proof casing 4 and X-ray emission on the casing window 401. Among them, the X-ray transmission modulation system 2 is composed of a wide-band beam-limiting diaphragm 201, a monochromator 202, and a narrow-band beam-limiting diaphragm 203 coaxially, and the pseudothermal X-ray generation system 3 is composed of an encoding aperture plate 301 and its adjustment frame 302 , metal hole array plate 303 and its motion controller 304, chassis 305, guide rail 306 constitute. The thermal X-ray generated by the X-ray generator 1 propagates through free space, first reaches the X-ray transmission modulation system 2, and enters the monochromator 202 after being limited by the broadband beam limiting diaphragm 201, and is filtered by the monochromator 202 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com