On-orbit assembly system of very large space telescope based on multi-space robot

A technology for space telescopes and assembly systems, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of poor carrying and propulsion capabilities of launch vehicles, and the inability to meet the needs of ultra-large-caliber space optical loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

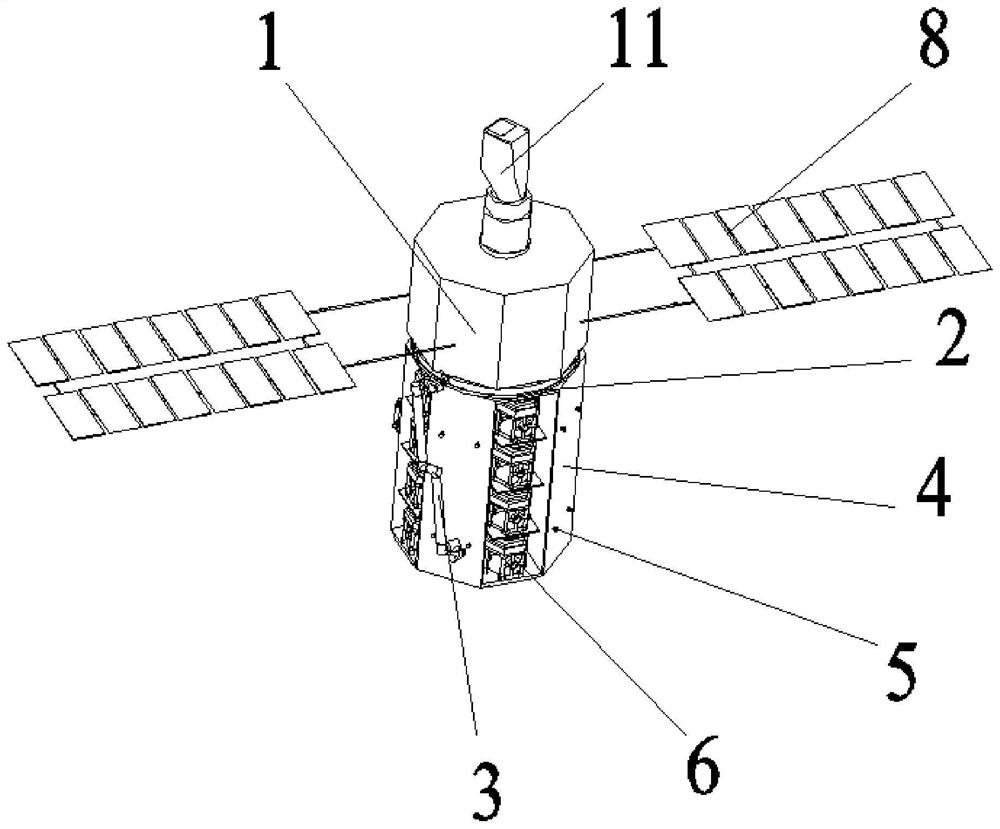

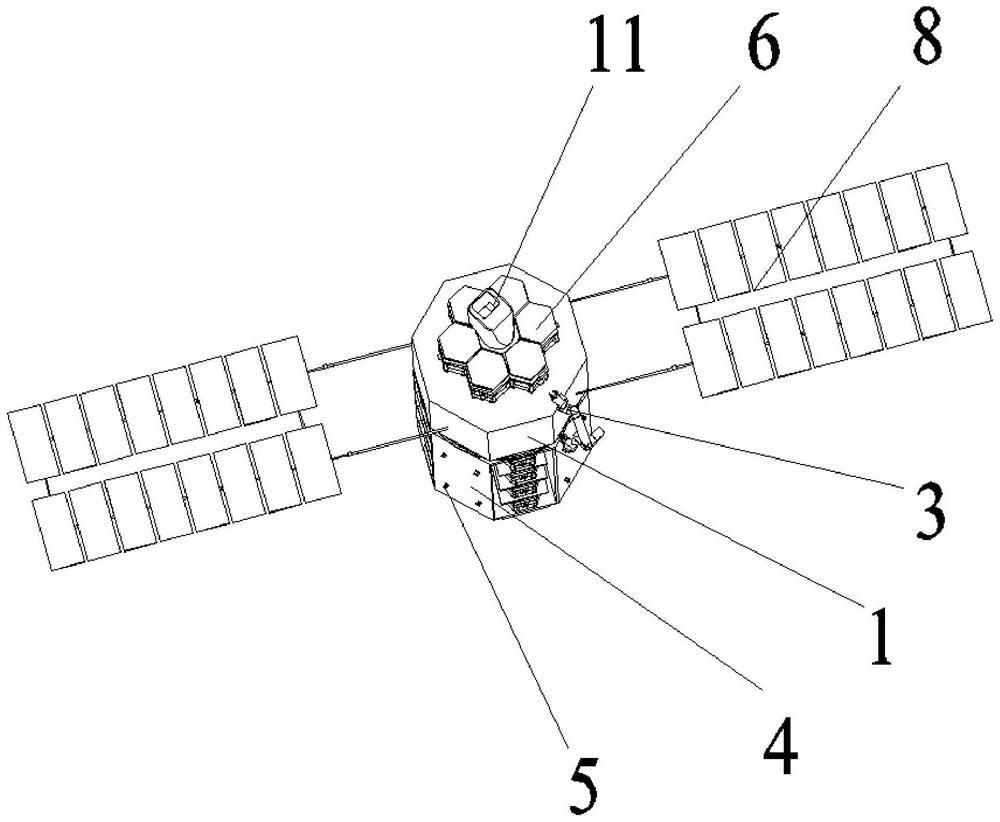

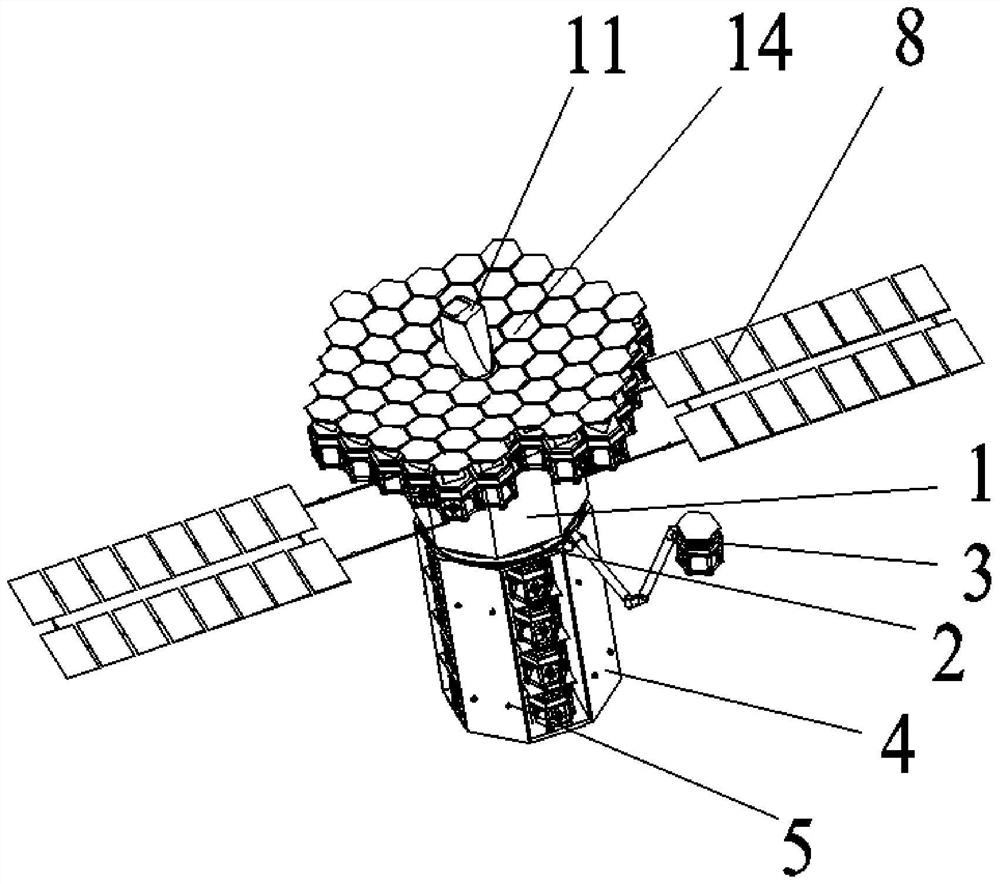

[0025] Specific implementation mode one: refer to Figure 1 to Figure 5 This embodiment is described. This embodiment provides an on-orbit assembly system for a very large space telescope based on a multi-space robot. The three-mirror module 11 and two solar wing sail panels 8, the three-mirror module 11 is positioned on the axis of the spacecraft platform 1, and the three-mirror module 11 is fixedly connected to the top of the spacecraft platform 1, and the two solar wing sail panels 8 Equidistantly installed on the outer circular surface of the spacecraft platform 1 along the circumferential direction, the metering ring 2 is arranged below the spacecraft platform 1, and one end of the metering ring 2 is fixedly connected to the bottom of the spacecraft platform 1, and the cargo compartment 4 is arranged on the The lower part of the metering ring 2, and the cargo compartment 4 is disassembled and connected with the metering ring 2, the telescopic robot arm 3 is arranged on th...

specific Embodiment approach 2

[0027] Specific implementation mode two: refer to Figure 1 to Figure 5 This embodiment is described. This embodiment is to further limit the telescopic robotic arm 3 described in the first specific embodiment. In this embodiment, the telescopic robotic arm 3 is connected to the sliding block through a ball joint. Other compositions and connection methods are the same as those in Embodiment 1.

[0028] In this embodiment, the telescopic mechanical arm 3 is slidingly connected to the metering ring 2 through a sliding block, so that the telescopic robotic arm 3 can perform a 360° circular rotation along the axis of the metering ring 2. The telescopic robotic arm 3 itself has 9 The degree of freedom includes 7 degrees of freedom of rotation of joints and 2 degrees of freedom of movement of arms. The telescopic manipulator 3 is hinged with the sliding block to realize that the telescopic manipulator 3 can swing relative to the metering ring 2 .

specific Embodiment approach 3

[0029] Specific implementation mode three: refer to Figure 1 to Figure 5 Describe this embodiment, this embodiment is to further limit the cargo compartment 4 described in the second specific embodiment, in this embodiment, the cargo compartment 4 is a cylindrical structure, and the cargo compartment 4 is sequentially provided with modular Sub-mirror discharge cabin, secondary mirror module discharge cabin, secondary mirror bracket discharge cabin, halo structure mounting base discharge cabin and halo structure discharge cabin, several modular sub-mirrors 6, secondary mirror modules 9, The three secondary mirror brackets 10, the light blocking ring structure 12 and the light blocking ring structure mounting base 13 are correspondingly placed in each discharge compartment. Other compositions and connection methods are the same as those in the second embodiment.

[0030] In such a setting, the original overall large-scale space telescope will be split into various parts, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com