Preparation method of anti-counterfeiting self-adhesive label

A label and label paper technology, used in printing, information-carrying cards, cardboard items, etc., can solve the problems of folds between the surface paper and the backing paper, waste of glue, no glue scraping and collection, etc., so as to avoid wasting glue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

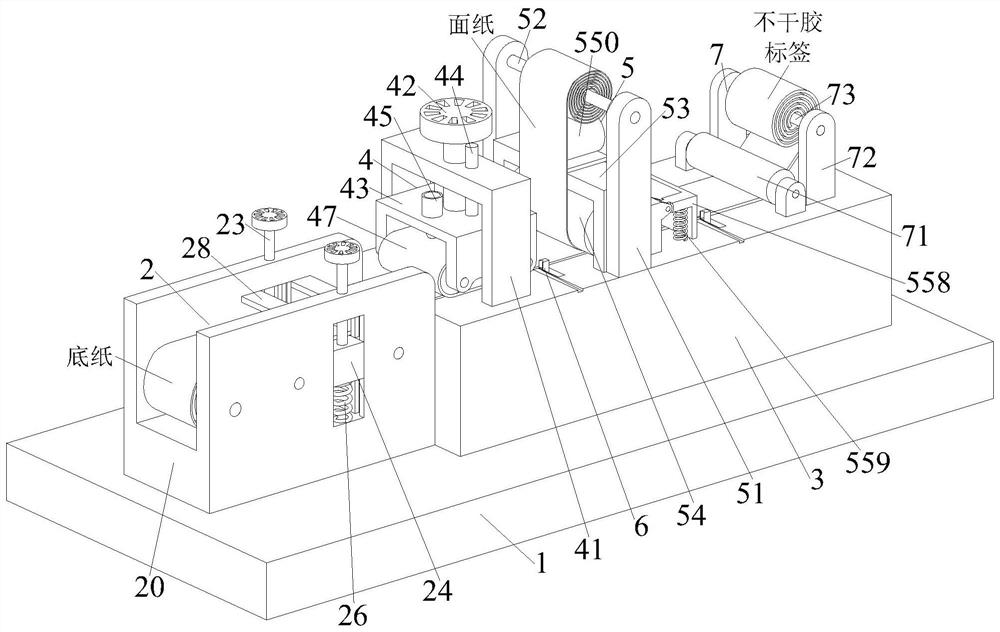

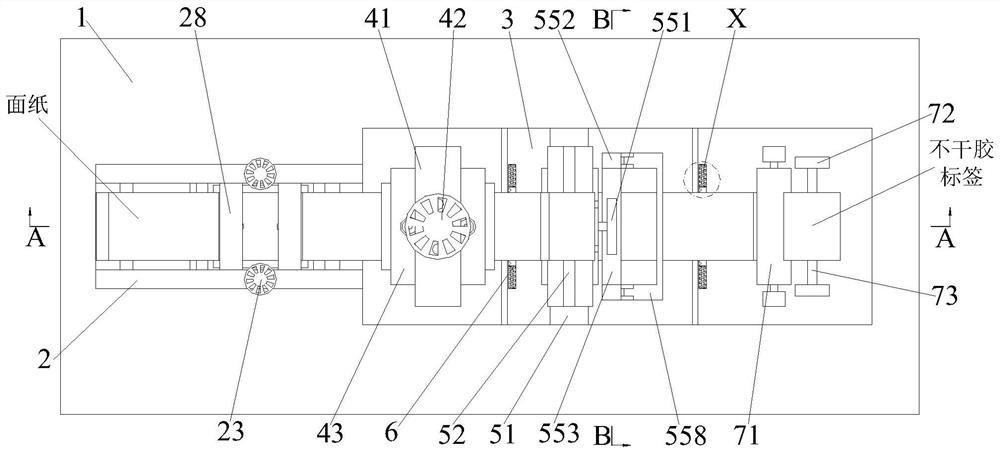

[0039] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

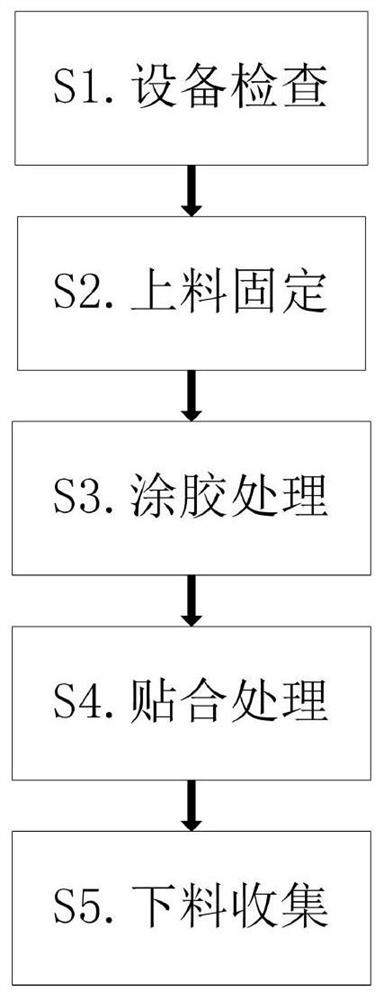

[0040] A method for preparing an anti-counterfeit self-adhesive label, the specific preparation method is as follows:

[0041] S1. Equipment inspection: check the anti-counterfeit self-adhesive label making equipment before using it to make anti-counterfeit self-adhesive labels;

[0042] S2. Loading and fixing: manually place the bottom paper and the face paper on the feeding device 2 and the laminating device 5 respectively, and wind the bottom paper and the face paper through the winding device 7;

[0043] S3. Gluing treatment: after the loading is completed, the upper surface of the backing paper is glued by the glue coating device 4;

[0044] S4. Bonding treatment: after the bottom paper is glued, the surface paper is pasted on the bottom pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com