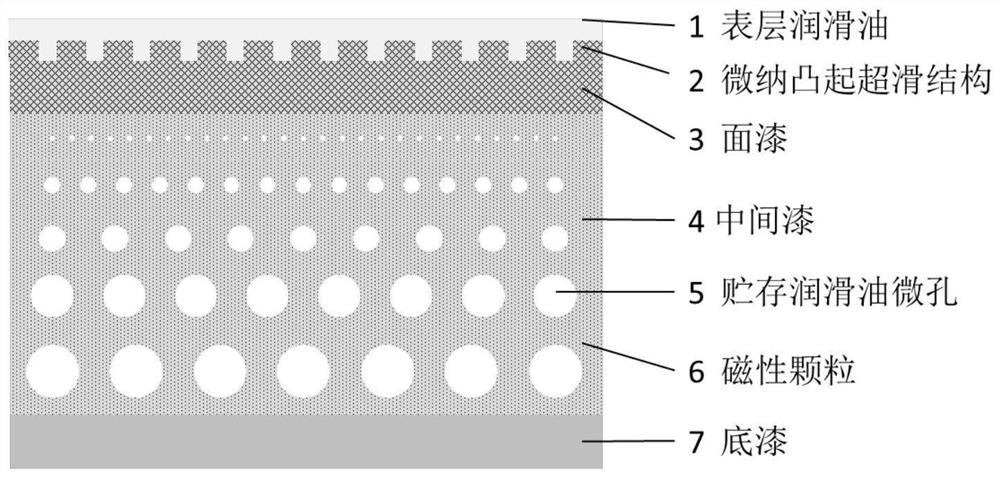

A magnetically responsive dynamic self-secretion coating and its preparation method and application method

A self-secretion and magnetic response technology, applied in coatings, polyether coatings, anti-corrosion coatings, etc., can solve problems such as loss of protective functions, achieve the effects of improving oil storage rate, increasing porosity, and enhancing coating protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

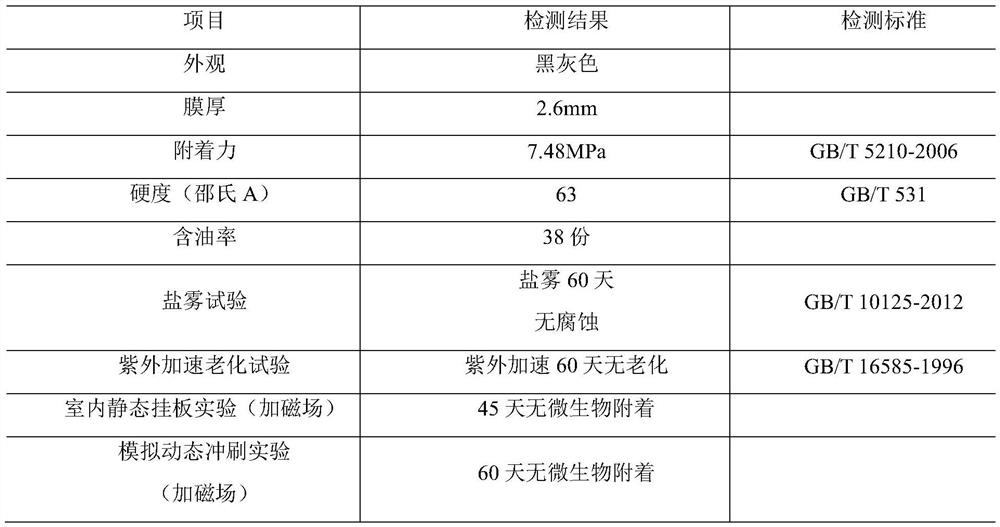

Examples

Embodiment 1

[0043] 1) Primer preparation process:

[0044] Take 100g of powdered filler aluminum tripolyphosphate with particle size of 1000 mesh, 30g of zinc chrome yellow, 35g of flake zinc powder, and 12g of polyaniline, and mix them evenly to prepare composite antirust filler. Take 1000g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 15000cp, and 120g of dimethyl silicone oil with a viscosity of 100cp, put them into a vacuum kneader, and mix them with the prepared anti-rust filler evenly. Under the condition of 90° C., after vacuum stirring for 2 hours, transfer to a grinder and grind for 0.5 hour. After the coarse material is crushed, transfer it to a high-speed mixer, add 35g of dimethyl silicone oil, 22g of methyloxime silane, 20g of chain extender ethyl orthosilicate, 12g of aminopropyltriethoxysilane, methyltrimethoxy 10g of silane; 2g of organotin catalyst, stirred at 600r / min for 1h under vacuum condition, vacuum packaged after delivery to obtain the finished ...

Embodiment 2

[0055] 1) Preparation of primer:

[0056] Take 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 10000, and 10 parts of dimethyl silicone oil with a viscosity of 100cp, and mix them to obtain a resin base material; take 5 parts of aluminum tripolyphosphate with a particle size of 800 mesh, 2 parts of zinc chrome yellow, 5 parts of flaky zinc powder and 1 part of polyaniline were used to prepare the composite anti-rust filler; the resin base material and the composite anti-rust filler were added to the vacuum kneader, stirred at 80°C for 3 hours, then transferred to the grinder to grind for 0.5 Hours; after the grinding material is cooled, turn the vacuum high-speed mixer, take 3 parts of dimethyl silicone oil with a viscosity of 100cp, 2 parts of methyloxime silane, 1 part of chain extender tetraethyl orthosilicate, aminopropyltriethoxy 1 part of silane, 1 part of methyltrimethoxysilane, 0.1 part of organotin catalyst, mixed and stirred for 1 hour under...

Embodiment 3

[0064] 1) Preparation of primer:

[0065] Take 120 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 20000, 20 parts of dimethyl silicone oil with a viscosity of 500cp, and mix them to obtain a resin base material; take 10 parts of aluminum tripolyphosphate with a particle size of 1000 mesh, 5 parts of zinc chrome yellow, 20 parts of flaky zinc powder and 2 parts of polyaniline were used to prepare composite anti-rust fillers; the resin base material and composite anti-rust fillers were added to a vacuum kneader, stirred for 4 hours under vacuum at 100°C, and then transferred to a grinder for grinding for 1 Hours; after the grinding material is cooled, turn the vacuum high-speed mixer, take 5 parts of dimethyl silicone oil with a viscosity of 500cp, 5 parts of methyloxime silane, 2 parts of chain extender ethyl orthosilicate, aminopropyl triethoxy 5 parts of silane, 3 parts of methyltrimethoxysilane, 0.3 parts of organotin catalyst, mixed and stirred for 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com