Movable formwork cast-in-place beam maintenance method and maintenance system

A technology of mobile formwork and maintenance system, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc. It can solve problems affecting the quality of box girders, over-maintenance, and poor sustainability, so as to facilitate repeated use and continuous maintenance, and meet the requirements of spraying. Showing demand and ensuring sustainable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with drawings and embodiments.

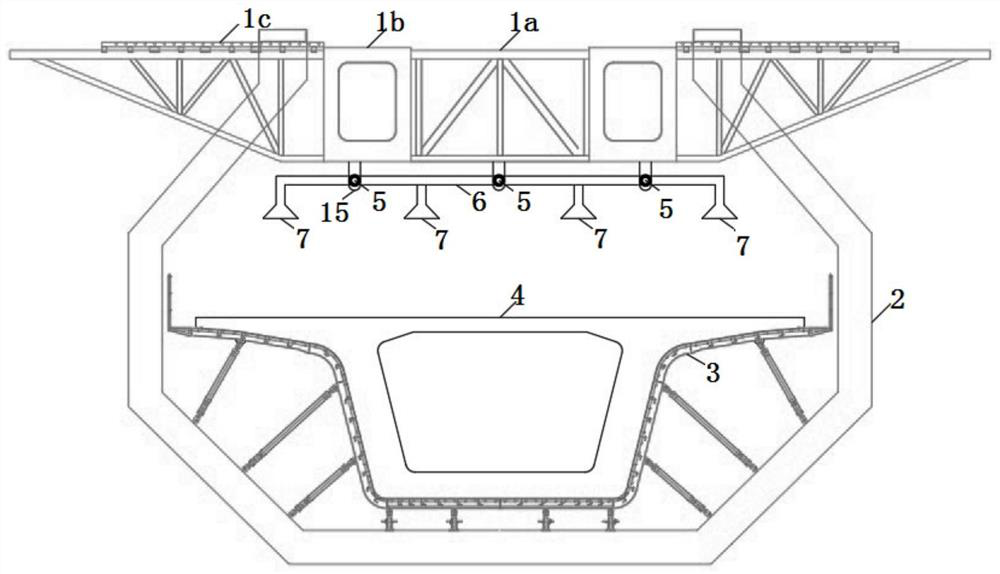

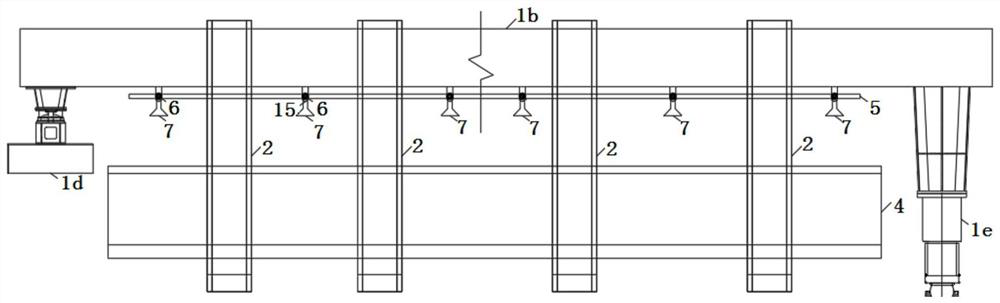

[0040] refer to Figure 1 to Figure 4, the invention provides a mobile formwork cast-in-place beam maintenance method, comprising the following steps:

[0041] (1) Fix the maintenance water pipe between the mobile formwork and the beam surface 4 before the mobile formwork passes through the hole, so that the spray coverage of all the maintenance nozzles 7 installed on the maintenance water pipe covers the entire beam surface;

[0042] (2) Set the first maintenance time period, and carry out spray maintenance on the beam surface within the first maintenance time period;

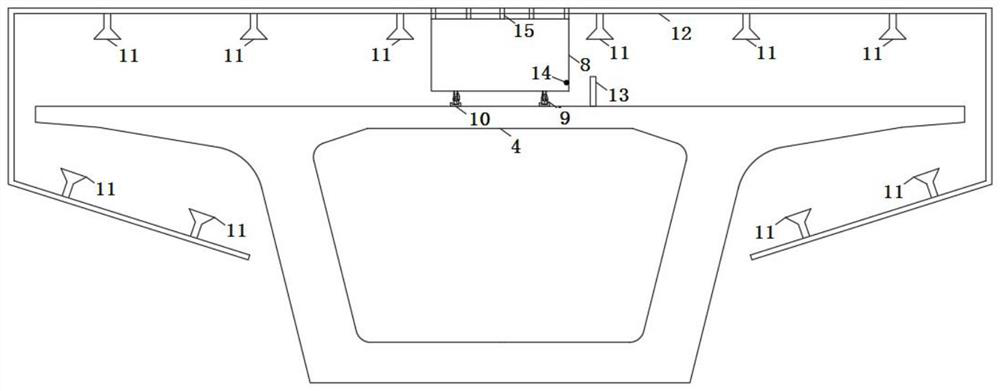

[0043] (3) After moving the formwork through the hole, lay the track 10 along the extension direction of the beam surface, erect the intelligent maintenance trolley 8 on the track, and erect the trolley maintenance water pipe 12 on the intelligent maintenance trolley, so that the maintenance nozzles on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com