An automatic assembly line for needle roller bearings

A technology for automatic assembly and needle roller bearings, which is applied to shafts and bearings, bearing components, mechanical equipment, etc., and can solve problems such as manual participation in assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

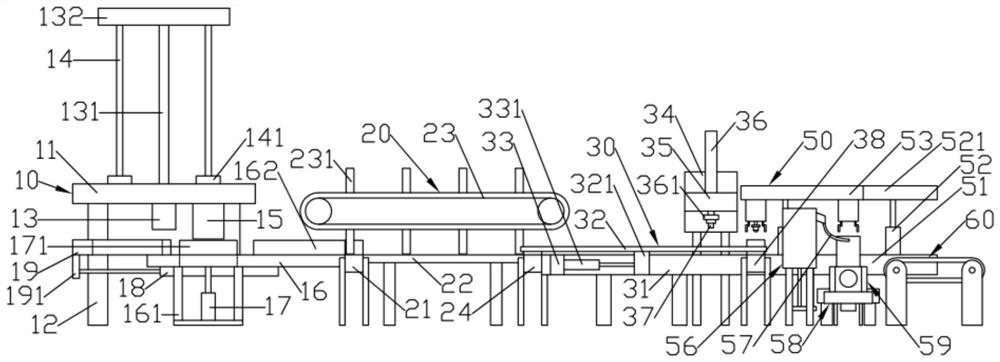

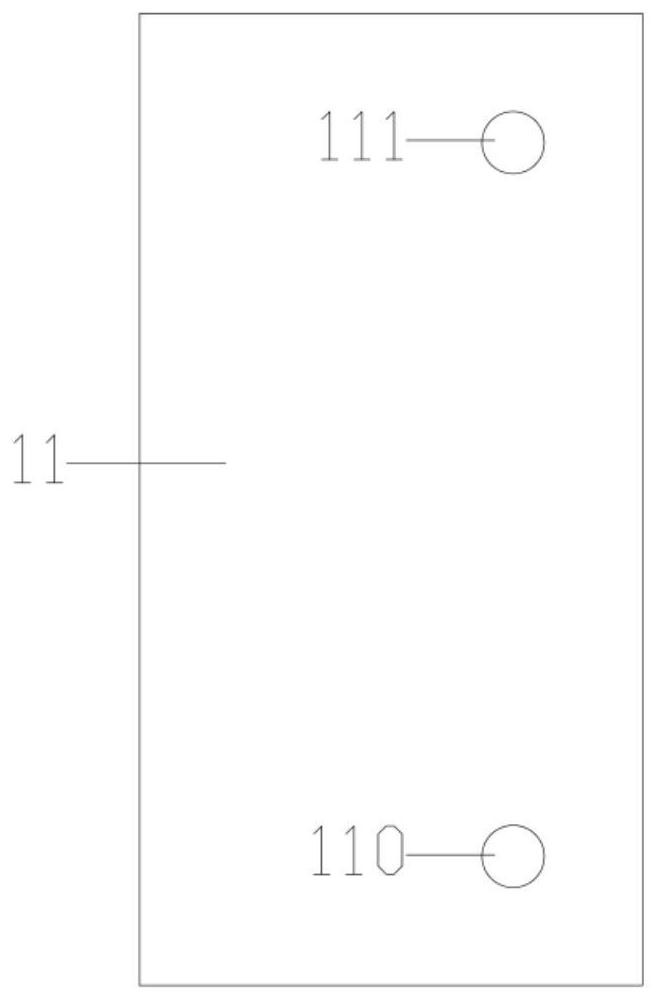

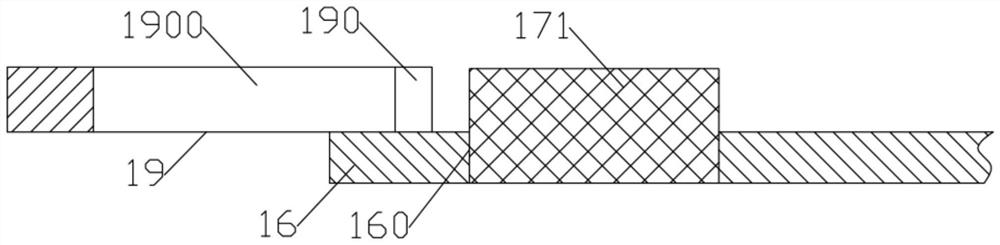

[0024] Such as Figure 1 to Figure 8 As shown, an automatic assembly line for needle roller bearings includes a feeding device 10, a conveying device 20, an inner and outer fitting device 30, an assembly device 50, and a discharge conveyor belt 60 arranged from left to right; the feeding device 10 includes a feeding Center plate 11; the bottom surface of the feed center plate 11 is provided with a number of evenly distributed feed support feet 12; the right rear end of the feed center plate 11 is formed with an inner ring blanking hole 111 that penetrates up and down, and the right front end is formed with an up and down The penetrating outer ring blanking hole 110; a pair of annular cylindrical lower guide sleeves 15 are fixed on the bottom surface of the feeding center plate 11; the pair of lower guide sleeves 15 are respectively facing the inner ring blanking hole 111 and the outer ring drop Material hole 110; the front end of the upper end of the feeding center plate 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com